Surge control system of compressor unit

A technology of surge control and compressor unit, which is applied in the direction of pump control, mechanical equipment, machine/engine, etc. It can solve the problems of slow execution speed, restriction of unit performance, service life of unit, and high cost of long-term operation, so as to achieve fast response speed, The effect of reducing operation failure rate and long-term operation cost and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

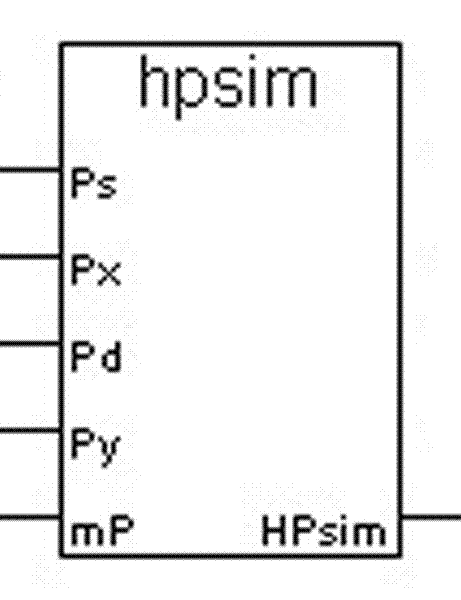

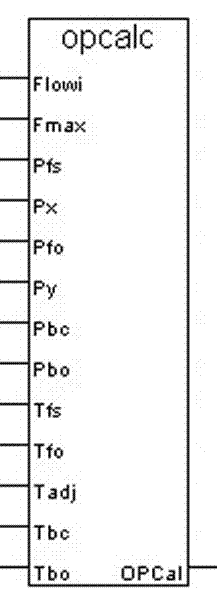

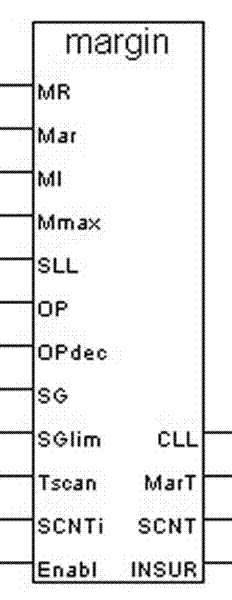

[0032] As shown in the figure, the present invention includes a controller, a high-speed pressure transmitter, a throttling device, a temperature sensor, and an anti-surge regulating valve; connected.

[0033] The high-speed pressure transmitter detects the inlet and outlet pressure of the compressor and converts it into a standard analog signal and sends it to the controller.

[0034] The throttling device detects the compressor inlet or outlet flow and converts it into a standard analog signal and sends it to the controller.

[0035] The temperature sensor detects the inlet and outlet temperature of the compressor and converts it into a standard analog signal and sends it to the controller.

[0036] The controller receives the pressure, flow, and temperature signals input from the high-speed pressure transmitter, throttling device, and temperature sensor, and outputs a surge control signal through calculation to control the anti-surge valve to adjust the suction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com