Method for dyeing wool quickly at low temperature

A rapid dyeing and wool technology, applied in the field of wool dyeing, can solve the problems of large damage to wool fibers, failure to satisfy manufacturers, and long process, and achieve the effect of retaining inherent characteristics, good economic and social benefits, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

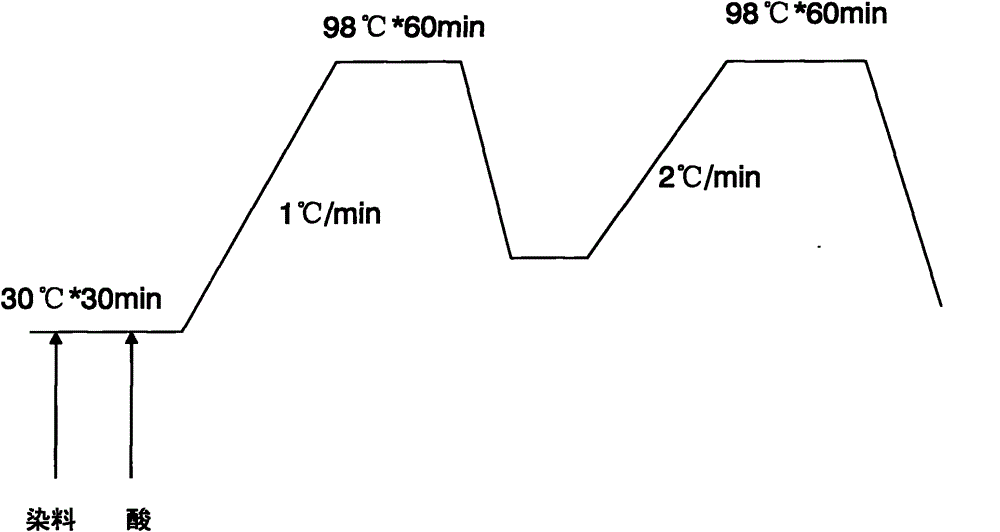

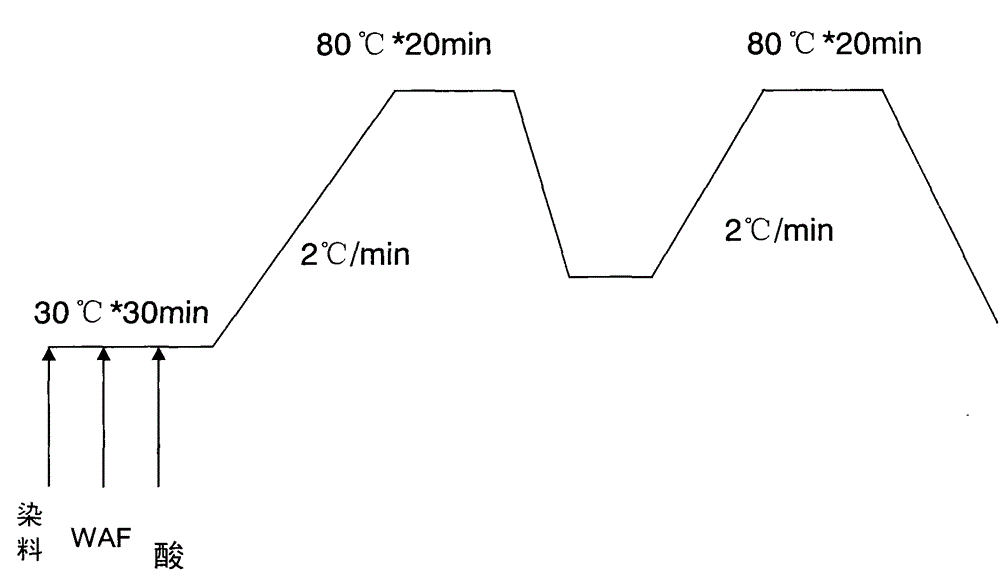

Method used

Image

Examples

Embodiment 1

[0025] The low-temperature quick dyeing method of wool of the present invention comprises: the preparation of leveling agent, the preparation of dye liquor and the low-temperature dyeing of wool, wherein:

[0026] 1) The leveling agent is made of the following raw materials in weight ratio:

[0027] Get 15 kilograms of sodium acetate; 25 kilograms of aromatic polyether sodium benzene sulfonate, 5 kilograms of sodium bisulfite, 15 kilograms of n-amyl alcohol, 1000 kilograms of water;

[0028] The preparation steps are as follows:

[0029] Weigh sodium acetate according to the proportion of the formula, add it to water, dissolve and stir evenly, adjust the pH value to 4.5 with glacial acetic acid, then add aromatic polyether sodium benzenesulfonate, sodium bisulfite, and n-amyl alcohol, and then uniformly mix in a constant temperature oscillator Stir for 30min and set aside;

[0030] 2) The dye liquor is made from the following raw materials in weight ratio:

[0031] Dye: 2 k...

Embodiment 2

[0038] The low-temperature quick dyeing method of wool of the present invention comprises: the preparation of leveling agent, the preparation of dye liquor and the low-temperature dyeing of wool, wherein:

[0039] 1) The leveling agent is made of the following raw materials in weight ratio:

[0040] Get 25 kilograms of sodium acetate; 35 kilograms of aromatic polyether sodium benzene sulfonate, 15 kilograms of sodium bisulfite, 25 kilograms of n-amyl alcohol, 1000 kilograms of water;

[0041] The preparation steps are the same as in Example 1.

[0042] 2) The dye liquor is made from the following raw materials in weight ratio:

[0043] Dye: 8 kg, leveling agent: 5 kg, water 1000 kg;

[0044] Dyes include:

[0045] The preparation steps are the same as in Example 1.

[0046] 3) The low-temperature dyeing procedure of wool is the same as in Example 1.

Embodiment 3

[0048] 1) The leveling agent is made of the following raw materials in weight ratio:

[0049] Get 20 kilograms of sodium acetate; 28 kilograms of aromatic polyether sodium benzene sulfonate, 8 kilograms of sodium bisulfite, 18 kilograms of n-amyl alcohol, and 1000 kilograms of water; the preparation steps are the same as in Example 1.

[0050] 2) The dye liquor is made from the following raw materials in weight ratio:

[0051] Dye: 3 kg, leveling agent: 1.5 kg, 1000 kg of water; the preparation steps are the same as in Example 1.

[0052] Dyes include:

[0053] 3) The low-temperature dyeing procedure of wool is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com