Desanding method used in process for producing ethanol by adopting cassava

A production process and technology for ethanol, applied in the field of ethanol production from cassava, can solve the problems affecting the service life of equipment, loss of cassava starch, and reduction of alcohol yield, etc., so as to improve energy utilization rate, reduce starch loss, and reduce the amount of processed materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

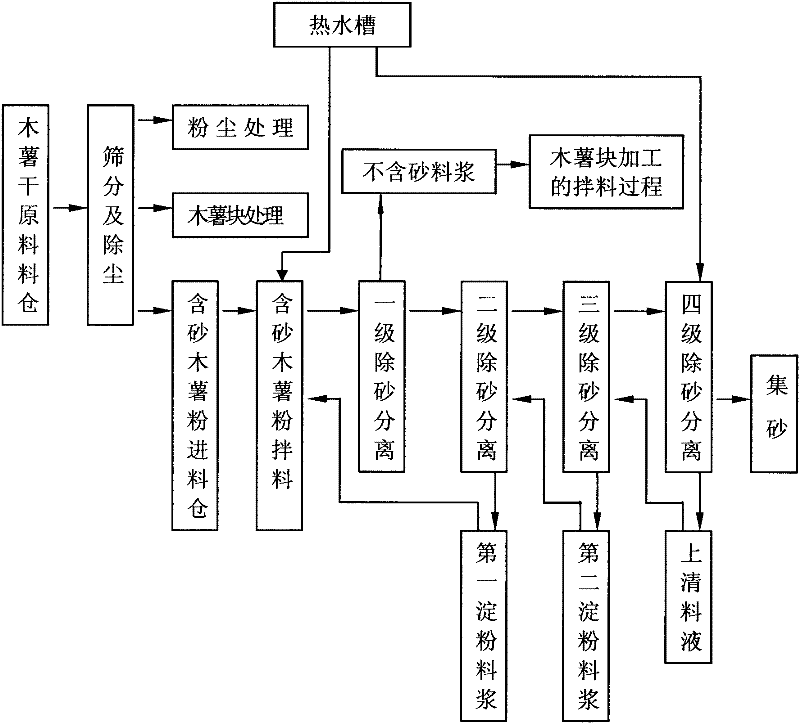

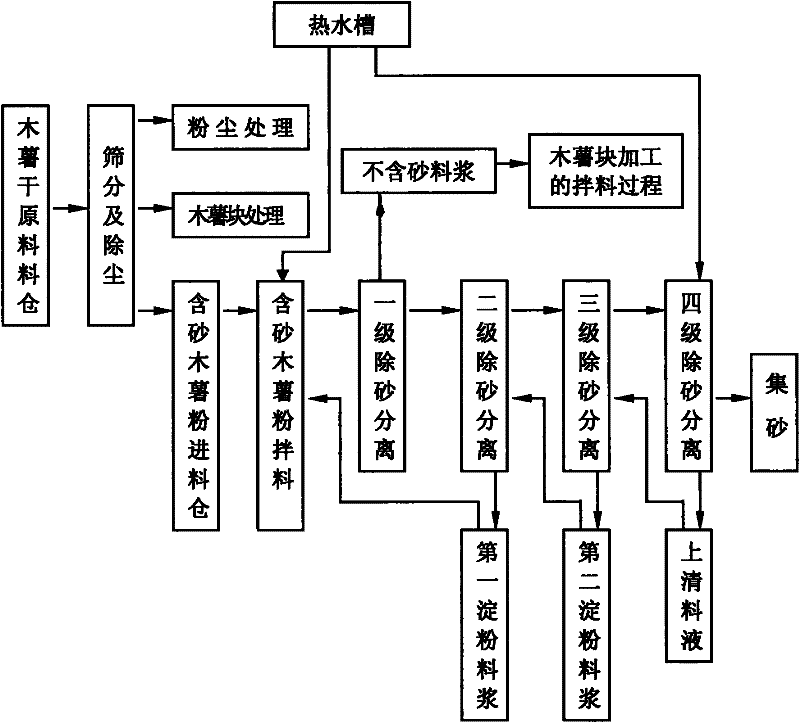

Image

Examples

Embodiment 1

[0028] Mixing with sandy cassava flour: Sandy cassava flour is mixed in a mixing tank. Mix sandy cassava flour and hot water in a ratio of 1:3. After mixing, the temperature is 60°C. Add high-temperature-resistant amylase in an amount of 21u / g per gram of cassava flour. Stir evenly, and the number of revolutions of the agitator is 50 rpm / min, stirring and heat preservation for 40min.

[0029] First-stage sand removal and separation, the uniformly mixed cassava flour feed liquid is input into the upper part of the first-stage long strip-shaped square tank, kept at 60°C, stirred and settled, stirred evenly, and the rotation speed of the agitator is 60 rpm. Sand and material liquid are separated to obtain sand-containing sediment and sand-free material liquid. A grit collection tank is installed at the bottom of the long strip-shaped tank, and the grit collection tank is connected to an automatic unloader to obtain the first-stage Sandy cassava flour feed liquid is processed a...

Embodiment 2

[0036] Mixing with sandy cassava flour: Sandy cassava flour is mixed in a mixing tank. Mix cassava flour with sand and hot water in a ratio of 1:5, the temperature after mixing is 62°C, add high-temperature-resistant amylase, the addition amount is 30u / g per gram of cassava flour, stir evenly, and the number of revolutions of the agitator is 41 rpm / min, stirring and heat preservation for 60min.

[0037] First-stage sand removal and separation, the uniformly mixed cassava flour feed liquid is input into the upper part of the first-stage long strip-shaped square tank, kept at 62°C, stirred and settled, stirred evenly, and the rotation speed of the agitator is 50 rpm. Sand and feed liquid are separated to obtain sand-containing sediment and sand-free feed liquid. A grit collection tank is installed at the bottom of the long strip-shaped tank, and the grit collection tank is connected to an automatic unloader to obtain the first-stage sand-free liquid. The cassava flour feed liq...

Embodiment 3

[0044] Mixing with sandy cassava flour: Sandy cassava flour is mixed in a mixing tank. Mix sandy cassava flour and hot water in a ratio of 1:3. After mixing, the temperature is 62°C. Add high-temperature-resistant amylase in an amount of 27u / g per gram of cassava flour. Stir evenly, and the number of revolutions of the agitator is 45 rpm / min, stirring and heat preservation for 60min.

[0045] First-level sand removal and separation, the uniformly mixed cassava flour liquid is input into the upper part of the first-level long strip-shaped square tank, kept at 62°C, stirred and settled, stirred evenly, and the rotation speed of the agitator is 41 rpm. Sand and feed liquid are separated to obtain sand-containing sediment and sand-free feed liquid. A grit collection tank is installed at the bottom of the long strip-shaped tank, and the grit collection tank is connected to an automatic unloader to obtain the first-stage sand-free liquid. The cassava flour feed liquid is processed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com