Method suitable for rapidly extracting high quality RNA of polysaccharide polyphenol plant tissue

A technology of plant tissue and extraction method, applied in the field of RNA, can solve the problems of high quality of plant tissue RNA, loss of 5SRNA, inappropriate extraction, etc., and achieve the effect of no DNA pollution and high RNA quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

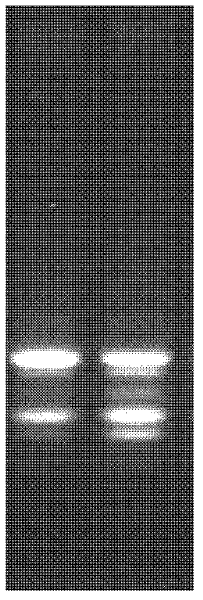

Image

Examples

Embodiment 1

[0023] Embodiment 1 Application reagent of the present invention and method extract the RNA of banana leaf and root

[0024] (1) Get each 200mg of fresh blade and root from banana seedlings and pulverize in liquid nitrogen;

[0025] (2) Add 1.2mL lysate preheated at 65°C to a 2mL centrifuge tube, add crushed plant tissue with liquid nitrogen, shake and mix;

[0026] (3) Add 600 μL of a mixture of chloroform and isoamyl alcohol, the volume ratio of chloroform and isoamyl alcohol is 24:1, shake and mix, and centrifuge at 8000 r / min at 4°C for 15 min;

[0027] (4) Take the supernatant, add 400 μL of precipitation solution, mix well, and precipitate at -20 ° C for 0.5 to 2 hours, then centrifuge at 12000 r / min below 4 ° C for 15 min;

[0028] (5) Discard the supernatant, precipitate with 500 μL of resuspension solution, add 500 μL of ice-cold water-saturated phenol (pH<5.0), shake and mix well, place on ice for 10 min, below 4°C, 12000 r / min, centrifuge for 15 min;

[0029] (6) ...

Embodiment 2

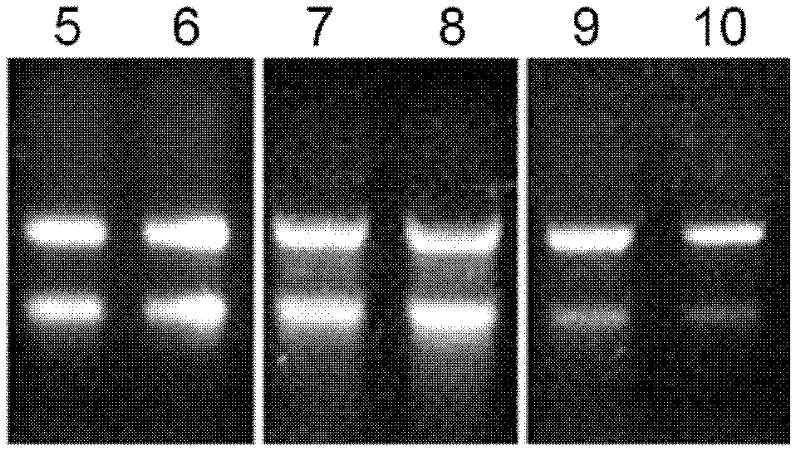

[0032] Embodiment two: application reagent of the present invention and method extract the RNA of banana pulp

[0033] (1) Get 100 mg of fresh young banana fruit and pulverize it in liquid nitrogen;

[0034] (2) Add 1.2mL lysate preheated at 65°C to a 2mL centrifuge tube, add crushed plant tissue with liquid nitrogen, shake and mix;

[0035] (3) Add 600 μL of a mixture of chloroform and isoamyl alcohol, the volume ratio of chloroform and isoamyl alcohol is 24:1, shake and mix well, centrifuge at 8000 r / min below 4 °C for 15 min;

[0036] (4) Take the supernatant, add 400 μL of precipitation solution, mix well, and precipitate at -20 ° C for 0.5 to 2 hours, then centrifuge at 12000 r / min below 4 ° C for 15 min;

[0037] (5) Discard the supernatant, precipitate with 500 μL of resuspension solution, add 500 μL of ice-cold water-saturated phenol (pH<5.0), shake and mix well, place on ice for 10 min, below 4°C, 12000 r / min, centrifuge for 15 min;

[0038] (6) Take the supernatant...

Embodiment 3

[0041] Embodiment three: application reagent of the present invention and method extract longan pulp RNA

[0042] (1) Get 100 mg of fresh longan pulp and pulverize it in liquid nitrogen;

[0043] (2) Add 1.2mL lysate preheated at 65°C to a 2mL centrifuge tube, add crushed plant tissue with liquid nitrogen, shake and mix;

[0044] (3) Add 600 μL of a mixture of chloroform and isoamyl alcohol, the volume ratio of chloroform and isoamyl alcohol is 24:1, shake and mix well, centrifuge at 8000 r / min below 4 °C for 15 min;

[0045] (4) Take the supernatant, add 400 μL of precipitation solution, mix well, and precipitate at -20 ° C for 0.5 to 2 hours, then centrifuge at 12000 r / min below 4 ° C for 15 min;

[0046] (5) Discard the supernatant, precipitate with 500 μL of resuspension solution, add 500 μL of ice-cold water-saturated phenol (pH<5.0), shake and mix well, place on ice for 10 min, below 4°C, 12000 r / min, centrifuge for 15 min;

[0047] (6) Take the supernatant, add 500 μL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com