Method for brewing yellow rice wine with extruded rice raw material with or without enzyme

A processing method and extrusion processing technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of large loss of raw rice, large equipment space, long processing time, etc., to improve the utilization rate of raw materials, shorten the fermentation period, and unique flavor. and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The rice raw material before extrusion has a water content of <17%. After being crushed or not, the water content is adjusted to 20%-60%. At the same time, no or an appropriate amount of enzyme preparation is added. Adding or adding an appropriate amount of enzyme preparation to the rice raw material, the temperature of the first sleeve, the second sleeve and the third sleeve is 30-60°C, 60-120°C and 120-190°C respectively, and the temperature can be adjusted automatically , the screw speed is 30rpm-500rpm, adjustable, extruded to obtain the rice raw material without adding or adding enzyme preparation, cooled and crushed for later use.

[0021] The above-mentioned processing method prepares the processing method of extruding rice wine raw materials without adding enzymes or adding enzymes for rice wine brewing, wherein the enzyme preparations added by extrusion include high-temperature-resistant α-amylase, medium-temperature α-amylase, and protease One or more of them,...

Embodiment 2

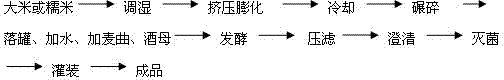

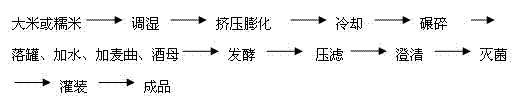

[0023] Embodiment 2: the process of brewing yellow rice wine from rice raw materials provided by the present invention.

[0024] Use extruded rice raw materials without adding enzyme preparations or adding enzyme preparations. After extrusion, the materials are cooled to room temperature in the air and then crushed. Add wheat koji at 10%-16% of the raw materials, and 8%-10% of the volume of the fermentation mash Add 12% distiller's mother, and the amount of water added is 200%-350% of the raw material. After mixing evenly, the product temperature is controlled at 24-26°C and enters the main fermentation. During the fermentation process, the temperature is controlled at 30-31°C, and the main fermentation is at 3-5 Complete within 2 days; then enter the post-fermentation stage, control the product temperature at 15-18 ℃, and ferment for 20-30 days; After pasteurization, filling and storage for half a year to one year, it is the finished rice wine.

[0025] The extrusion cooking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com