Method for extracting anthocyanin type components from wine grape pomace

A technology of grape pomace and anthocyanins, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of high toxicity and side effects, low extraction rate of products, and achieve easy organization and no pollution to the environment , The process steps are simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

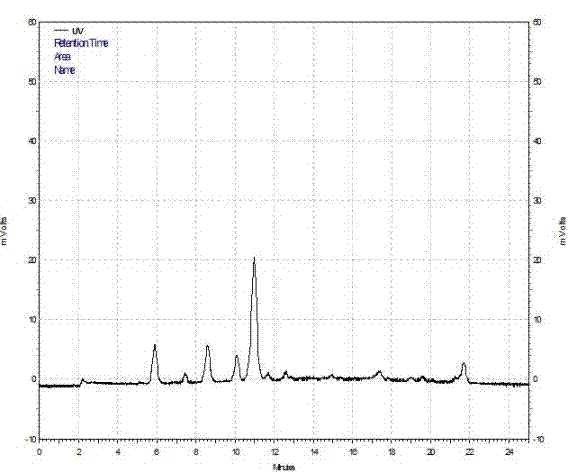

Image

Examples

Embodiment 1

[0031] (1) Evenly spray 10% of the total weight of purified water in the wine grape pomace, and ferment naturally in the extraction tank at 37-39°C for 40 hours;

[0032] (2) With 45% (volume fraction) ethanol that is 12 times the weight of raw materials, heat reflux extraction twice, each time for 2 hours;

[0033] (3) The two extracts are combined, concentrated in a vacuum, and ethanol is recovered to obtain the grape skin extract liquid;

[0034] (4) Extract the medicinal solution and pass through the AB-8 macroporous resin chromatography column, rinse with deionized water, elute with 2.5 times the column volume of 60% (volume fraction) ethanol aqueous solution, and collect the eluate;

[0035] (5) The eluate was concentrated in vacuum to a sugar content of 42°;

[0036] (6) The concentrated paste was spray-dried to obtain a product with an anthocyanin content of 9.76%.

Embodiment 2

[0038] (1) Evenly spray 10% of the total weight of purified water in the wine grape pomace, and ferment naturally in an extraction tank at 39-42°C for 36 hours;

[0039] (2) With 55% (volume fraction) ethanol that is 10 times the weight of raw materials, heat reflux extraction twice, each time for 2 hours;

[0040] (3) The two extracts are combined, concentrated in a vacuum, and ethanol is recovered to obtain the grape skin extract liquid;

[0041] (4) The extracted medicinal solution is passed through a polyamide chromatography column, washed with deionized water, eluted with 70% (volume fraction) ethanol aqueous solution twice the column volume, and the eluate is collected;

[0042] (5) The eluate was concentrated in vacuum to a sugar content of 42°;

[0043] (6) The concentrated paste was spray-dried to obtain a product with anthocyanin content of 12.36%.

Embodiment 3

[0045] (1) Evenly spray 20% of the total weight of purified water in the wine grape pomace, and ferment naturally in the extraction tank at 39-42°C for 36 hours;

[0046] (2) With 65% (volume fraction) ethanol that is 12 times the weight of raw materials, heat reflux extraction twice, each time for 2 hours;

[0047] (3) The two extracts are combined, concentrated in a vacuum, and ethanol is recovered to obtain the grape skin extract liquid;

[0048] (4) Extract the medicinal solution through the X-5 resin chromatography column, rinse with deionized water, elute with 4 times the column volume of 50% (volume fraction) ethanol aqueous solution, and collect the eluent;

[0049] (5) The eluate was concentrated in vacuum to a sugar content of 42°;

[0050] (6) The concentrated paste was spray-dried to obtain a product with an anthocyanin content of 8.34%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com