Flap aerated biological filter and wastewater treatment method thereof

A biological aerated filter and filter technology, applied in the direction of sustainable biological treatment, aerobic process treatment, etc., to achieve the effects of reducing construction difficulty, improving equipment utilization rate, and reducing consumption

Inactive Publication Date: 2012-03-28

惠州市铭博实业发展有限公司 +1

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a flap aerated biological filter and its sewage treatment method, to solve the technical problems of further ensuring the quality of aeration and backwashing of the filter and improving work efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

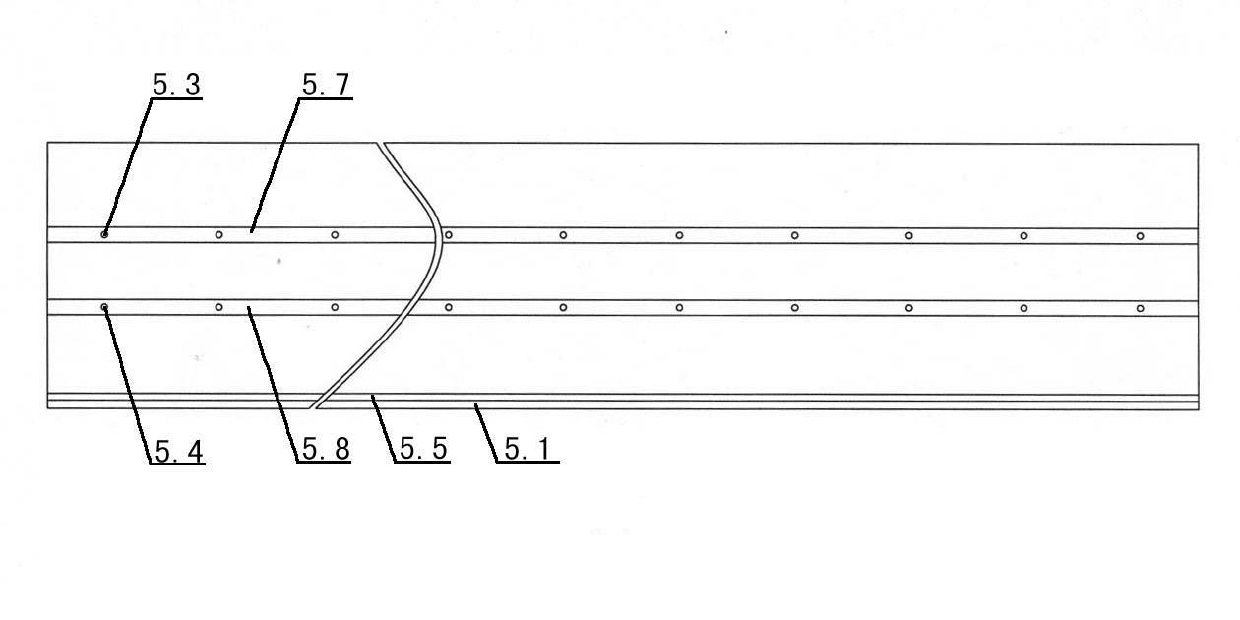

The invention relates to a flap aerated biological filter and a wastewater treatment method thereof. The flap aerated biological filter comprises a filter, water distribution pipes and gas distribution piped, wherein a water collecting channel with a rectangular section is arranged below the middle part of the bottom plate of the filter; the filter and the water collecting channel are divided into two layers by a water collecting channel partition; rows of water distribution pipes and gas distribution lateral pipes are arranged on the water collecting channel partition; a filtering material layer is paved on the water collecting partition; a flap valve is installed on one side of the filter wall; a backwashing water discharge channel is arranged outside the flap valve; a water inflow channel and an overflowing weir are arranged above the flap valve; the water distribution pipes and the gas distribution lateral pipes are buried in the filtering material layer, and are communicated withwater / gas distribution combined vertical pipes; and the filter wall at one side of the water collecting channel is communicated with outflow pipes of an aeration amount control valve and a backwashing gas control valve, an after-filtration water outflow pipe and a backwashing water inflow pipe. By the flap aerated biological filter, two independent aeration and backwashing gas distribution systems of a traditional biological filter are replaced, the investment is reduced, the construction difficulty is reduced and the use utilization of equipment is improved; and the flap aerated biological filter can be widely applied to wastewater treatment process of a biological filter.

Description

technical field The invention relates to a sewage treatment facility. Background technique Most of the traditional biological aerated filters currently in operation are V-shaped filter tanks. According to the flow direction of the sewage treatment process, they can be divided into upflow (UBAF) and downflow (DBAF). The two processes have their own advantages, but both have their own advantages. A common defect is that the aeration head and filter head of the filter, the air intake pipe and the backwash air pipe are all set independently, which not only increases the construction investment but also increases the construction difficulty. The bottom is assembled twice, and the flatness is not easy to control, resulting in uneven water and gas distribution. Because the traditional biological aerated filter only forms an air cushion filter at the bottom of the filter plate, the air pressure is not stable enough during aeration and air-water backwashing , affect the effect of a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F3/02

CPCY02W10/10

Inventor 汪平颜述敏杜海宽

Owner 惠州市铭博实业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com