Hoisting and turning-over device and method for large chemical container

A chemical and large-scale technology, applied in the direction of lifting devices, etc., can solve the problems of poor cylinder stability and damage to the gasifier cylinder, and achieve the effects of low manufacturing cost, convenient and reliable installation and disassembly, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

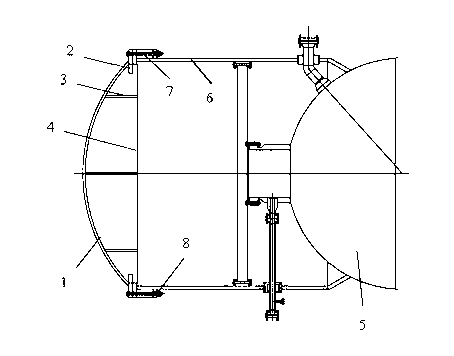

[0017] The following combination Figure 1 ~ Figure 4 , a preferred embodiment of the present invention is described in detail.

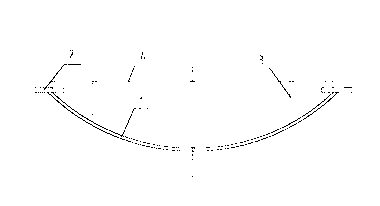

[0018] Such as figure 1 Shown is a schematic structural view of the lifting and turning device of the large chemical container of the present invention. It consists of arched components and connecting bolts 7 and nuts 8 . The arched assembly is connected with a large chemical container through connecting bolts 7 and nuts 8 . Among them, such as figure 2 As shown, the arch assembly includes an arc steel plate 1 and a supporting steel plate 4 ; The arch assembly further includes several ribs 3 arranged between the arc steel plate 1 and the supporting steel plate 4 for strengthening the supporting strength of the arch assembly.

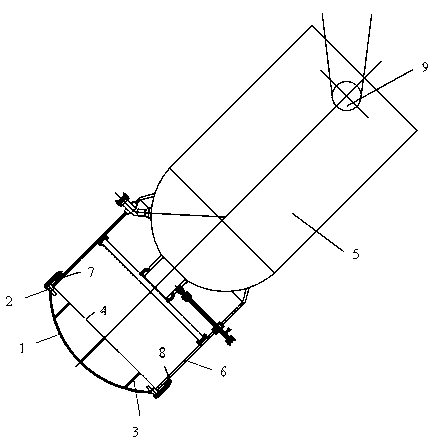

[0019] Such as image 3 with Figure 4 As shown, the method for turning over a large chemical container by using the lifting and turning device described in detail is described in detail, and the specific steps are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com