Material and flavor adding method and device capable of reducing liquid loss

A material liquid and material technology, applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of product quality degradation, deviation from process parameter values, and reduction of cigarette product feeding accuracy, so as to achieve low loss of material liquid, good feeding uniformity, The effect of high feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

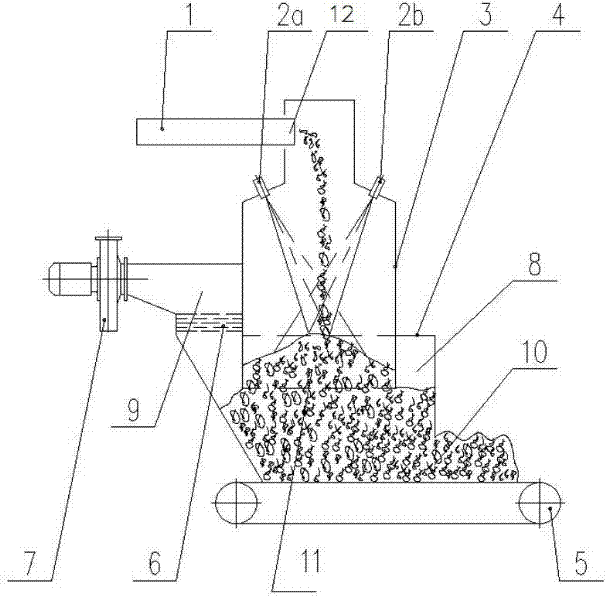

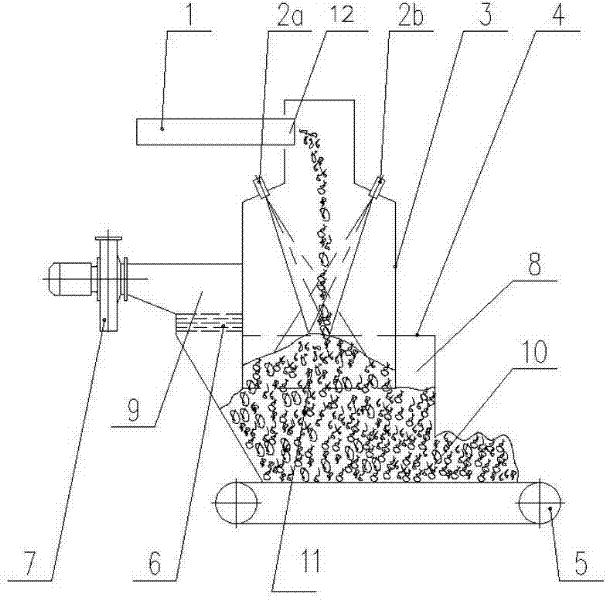

[0012] Such as figure 1 As shown, a method of feeding and flavoring to reduce the loss of the material liquid is to spray the atomized material liquid sprayed from the nozzle 2a to the material continuously falling from the upper part of the mixing chamber in the mixing chamber 3 to mix the material liquid and the material At the same time, negative pressure wind is applied below the material layer 11 falling to the bottom of the mixing chamber, and the atomized material liquid particles that are not adhered to the material and are still suspended above the material layer in the mixing chamber are sucked through the material layer and Filtration and absorption, further adhering the atomized particles of the material liquid to the material.

[0013] The materials described in the present invention are tobacco materials, such as shredded tobacco, tobacco leaves, tobacco stems, tobacco stem particles and the like.

[0014] Realize the feeding and perfuming device that reduces fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com