Display

A display and slit technology, applied in the display field, can solve the problems such as the reduction of the aperture ratio of the electrowetting display, the increase of the complexity of the driving system design, and the increase of the response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

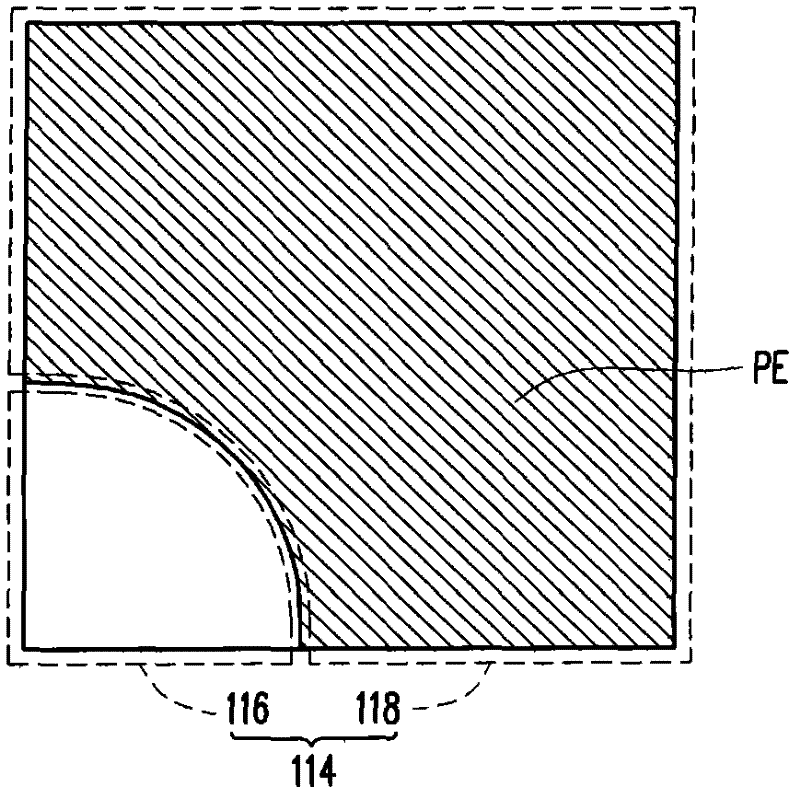

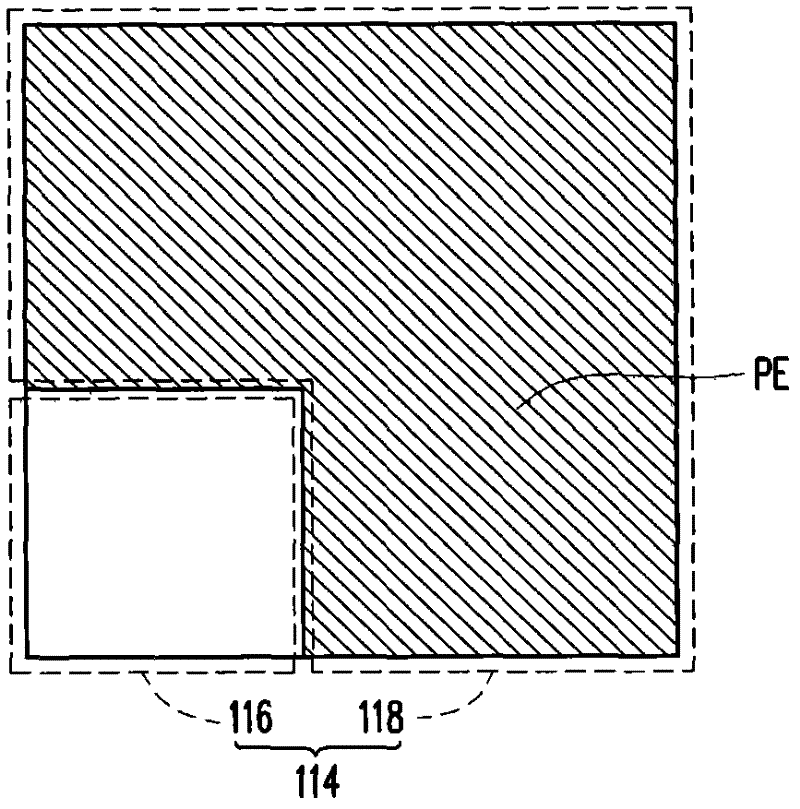

[0045] image 3 It is a partial top view cross-sectional schematic diagram of a display according to an embodiment of the present invention. Please refer to image 3 , the display 100 of this embodiment includes a pixel matrix substrate 110 , a pair of facing substrates 120 and a flow medium 130 . The pixel matrix substrate 110 includes a first substrate 112 and a plurality of pixel structures 200 . The pixel structures 200 are, for example, arranged in a matrix on the first substrate 112 .

[0046] In this embodiment, the opposite substrate 120 includes a second substrate 122 and a common electrode 124 , wherein the common electrode 124 is located on the second substrate 122 . The flow medium 130 includes a polar fluid 132 and a non-polar fluid 134 (in Figure 4A to Figure 4D represented by uniform dense dots), flows between the pixel matrix substrate 110 and the opposite substrate 120 , and the polar fluid 132 and the non-polar fluid 134 are not miscible with each other....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com