Method for determining productivity of diazomethane and method for preparing the diazomethane

A diazomethane and yield technology, applied in the preparation of test samples, material separation, instruments, etc., can solve the problem of reducing the yield of diazomethane and its conversion products, reducing the accuracy of diazomethane yield, side reactions, etc. problem, to achieve the effect of safety inspection of diazomethane yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The method for preparing diazomethane disclosed by the present invention comprises the steps of:

[0030] The dimethyl sulfoxide solution of the N-nitroso compound or the mixed solution of dimethyl sulfoxide and ether and the methanol solution of the strong base are mixed and reacted in the first micro-reaction device to obtain the first mixture including diazomethane . The first micro-reaction device preferably consists of a micro-mixer and a capillary micro-reactor. The time of the mixing reaction in the micro-mixer is extremely short, most of the reactions are carried out in the capillary microreactor, the total mixing reaction time is 10s~50s, and the mixing reaction is carried out in the first micro-reaction device The temperature ranges from 15°C to 45°C;

[0031] A sample of the first reaction mixture comprising diazomethane is mixed with the methanol solution of alkyl acetic acid or benzoic acid in the second micro-reaction device to obtain the second mixture ...

Embodiment 1

[0051] (1) At first, the dimethyl sulfoxide solution of the dimethylnitrosobenzene sulfonamide of 0.3mol / L is mixed with the methanol solution of 0.45mol / L potassium hydroxide in a micro mixer, and then the mixed The reaction mixture is passed into a capillary microreactor with an internal diameter of 1 mm to continue the reaction, and the reaction generates a diazomethane reaction mixture. The micromixer and the capillary microreactor are placed in a water bath, the reaction temperature is 20 ° C, and the reaction time is 39.2 s, the volumetric flow rate is 24ml / min.

[0052] (II) Then, the above-mentioned diazomethane reaction mixture is mixed with the methanol solution of 1.2mol / L isobutyric acid in another micromixer, and then the mixed reaction mixture is passed into a capillary microreactor with an internal diameter of 2mm Continue the reaction in the middle of the reaction to generate a reaction mixture of methyl isobutyrate. The micro-mixer and capillary micro-reactor ...

Embodiment 2~5

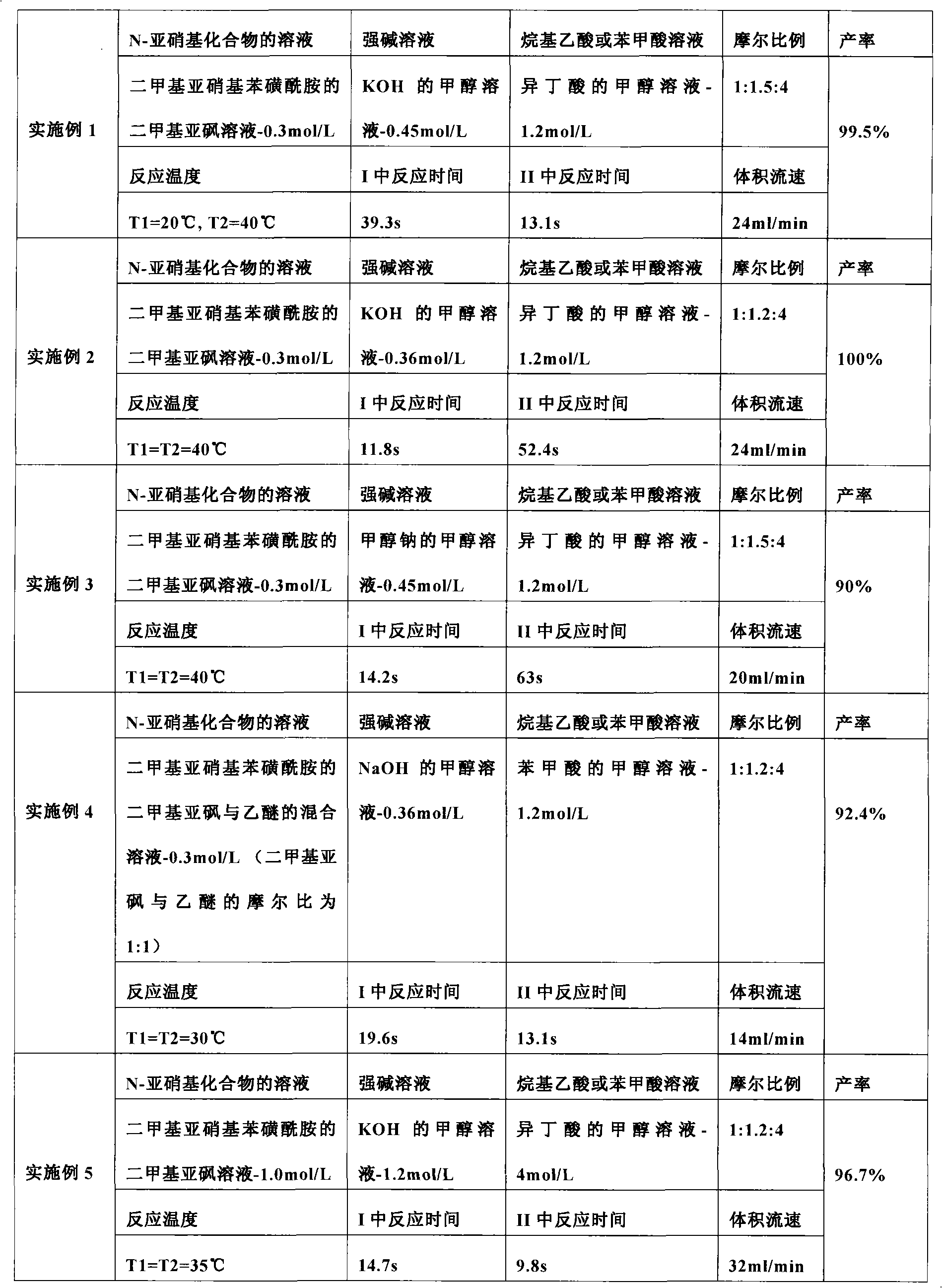

[0055] Compared with Example 1, except that the variables shown in the following table changed, Examples 2-5 adopted basically the same experimental device and basically the same experimental steps to achieve a high yield similar to that of Example 1.

[0056]

[0057] Compared with the prior art, the above examples disclose a relatively accurate method for measuring the yield of diazomethane within a certain range of data and a method for preparing diazomethane in a safe, continuous and high-yield manner, which is an important contribution to the diazomethane industry. The expansion of production on the Internet provides a feasible operation plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com