Testing device for rubber creeper tread abrasion loss performance and method

A rubber crawler and testing device technology, which is applied in the direction of measuring device, testing wear resistance, using stable tension/pressure testing material strength, etc., can solve the problems of long test period and only construction site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

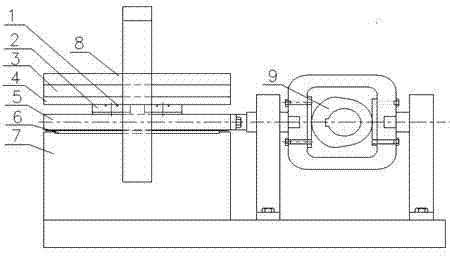

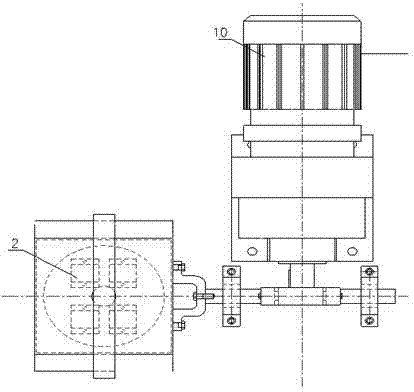

[0037] like figure 1 , figure 2 As shown, the test device for the wear performance of rubber track shoes includes: friction nail 1, heating plate 3, first pressing plate 4, sliding plate 5, wear-resistant plate 6, base 7, second pressing plate 8, transmission cam 9 and motor 10, etc. . in:

[0038] A sliding plate 5 is arranged on the base 7, and the sliding plate 5 can slide freely on the base 7; Above the sliding plate 5, the first pressing plate 4, the heating plate 3 and the second pressing plate 8 are successively installed, and there is a space for placing the rubber test piece 2 between the sliding plate 5 and the first pressing plate 4, and the lower part of the first pressing plate 4 Friction nails 1 are arranged on the surface.

[0039] Since the sliding plate 5 needs to slide freely, a wear-resistant plate 6 is fixed on the base 7 to reduce the frictional resistance between the sliding plate 5 and allow the sliding plate 5 to slide freely on the wear-resistant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com