Pressure sampling head of Pitotbar flow sensor

A technology of flow sensor and pressure-taking head, which is applied to the volume/mass flow generated by mechanical effects, and the direction of fluid flow detection by measuring differential pressure. It can solve the problem that the accuracy and precision are not very high and the pressure-taking effect is not very good problem, to achieve the effect of good pressure taking effect, high accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

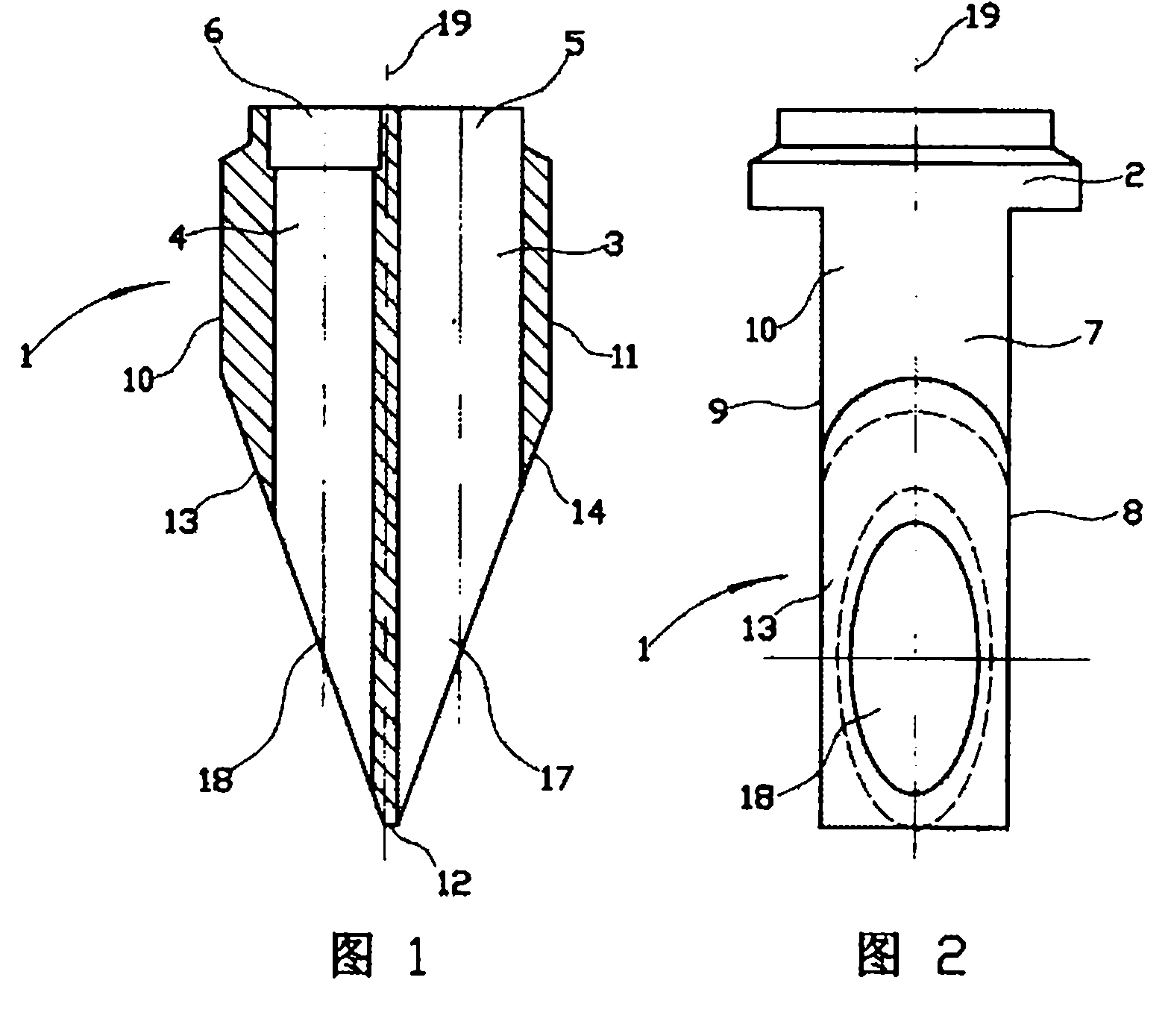

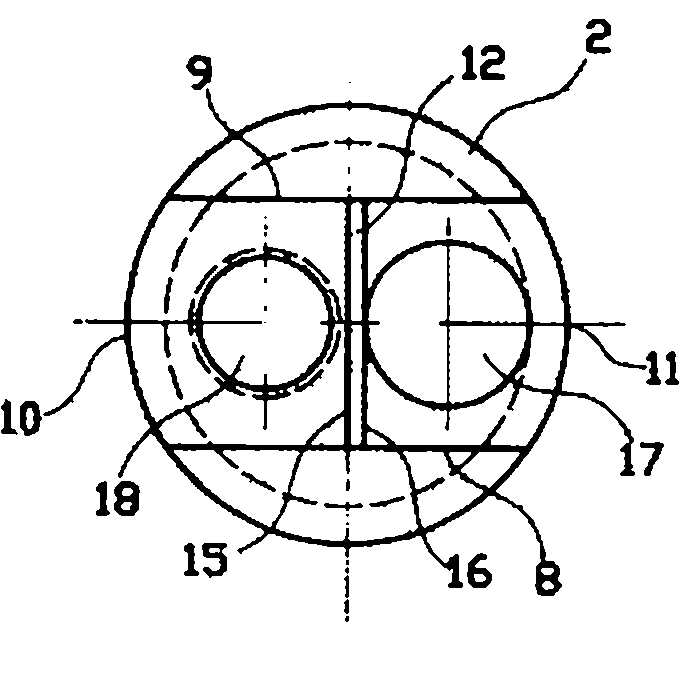

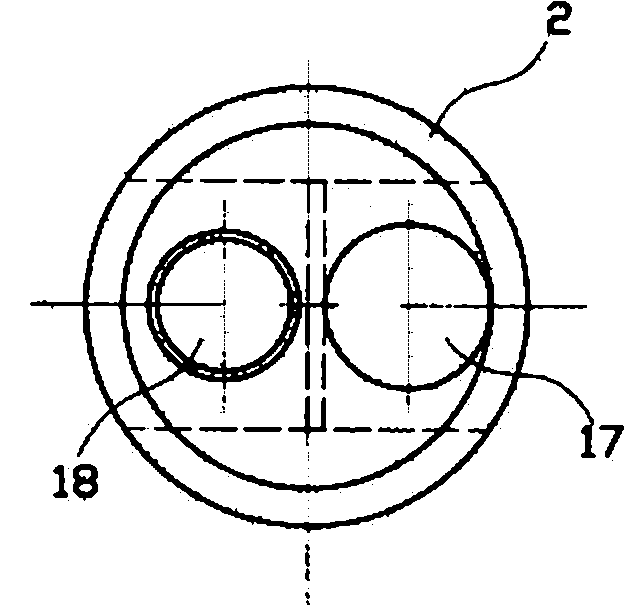

[0019] Figure 1~Figure 3 Among them, the pressure head of the Bitoba flow sensor has a pressure head body 1, and the upper end of the pressure head body has a cylindrical upper joint 2 perpendicular to the axis 19 of the pressure head body. The axis of the body is parallel to the total pressure channel 3 and the static pressure channel 4. The total pressure channel and the static pressure channel have the total pressure channel port 5 and the static pressure channel port 6 at the upper end of the pressure head body. The lower section of the pressure head body is the axis and the static pressure channel. Take the drum-shaped column 7 whose axis of the pressure head body is on the same straight line. The lower end surface 12 of the shaped column is perpendicular to the axis of the pressure head body, and there are left and right inclined surfaces 13, 14 respectively between the two arc surfaces and the lower end surface of the drum-shaped column. The angles of the included ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com