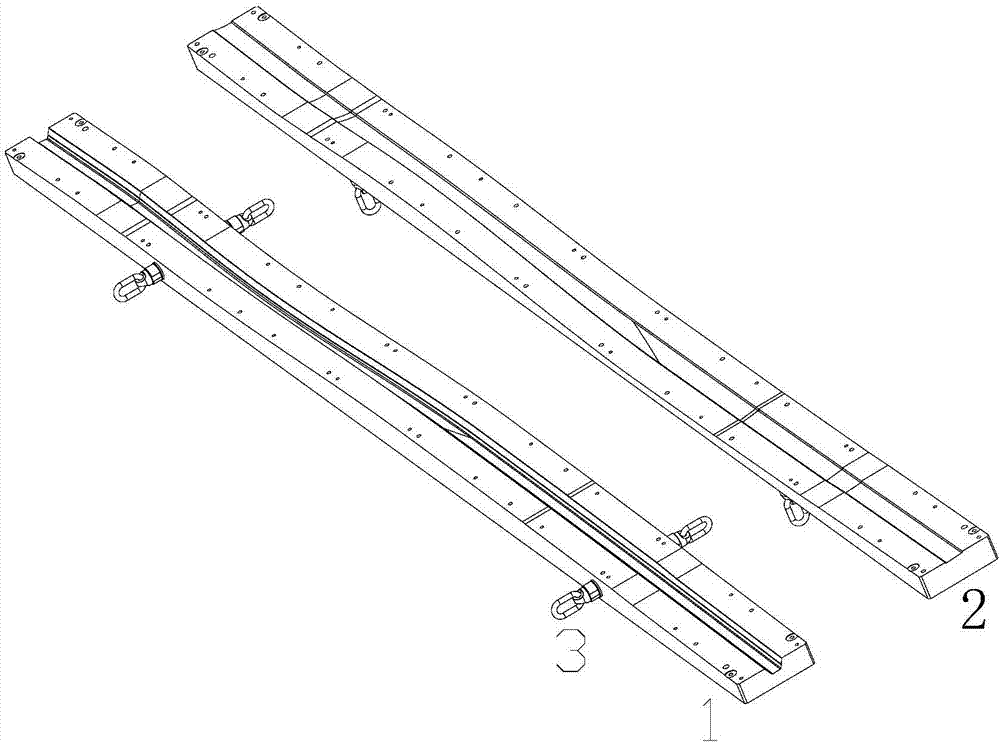

Airbag capable of being used for composite omega stringer co-curing forming

A technology of curing molding and airbags, which is applied in applications, household components, household appliances, etc. It can solve the problems of difficult control of rubber expansion, parts defects, and poor pressurization effect of long truss R angle, and achieve ideal pressurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

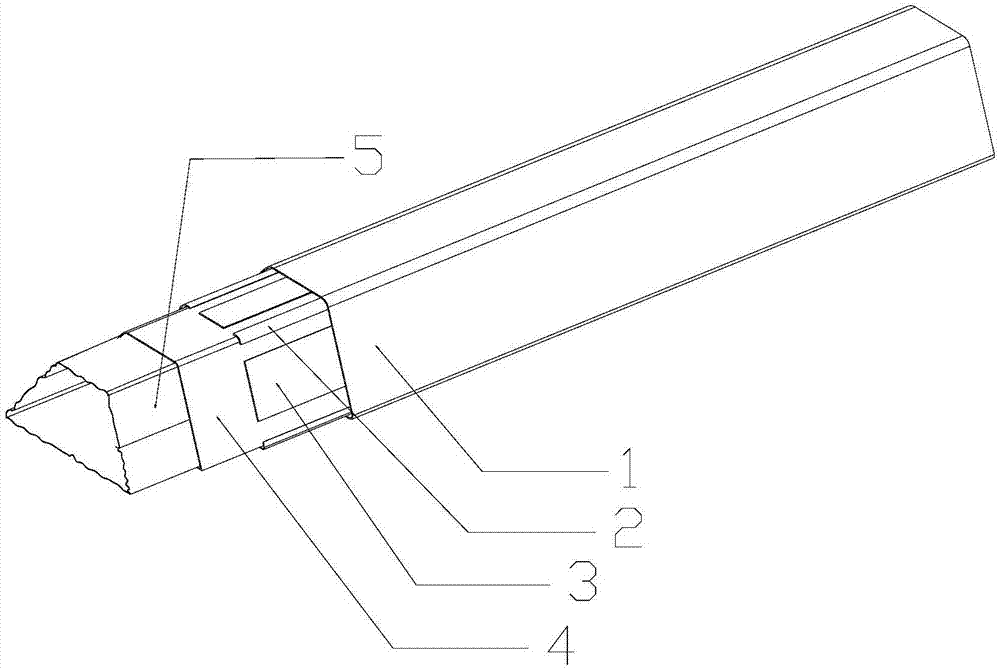

[0015] An airbag that can be used for co-curing molding of composite material Ω stringers, the airbag is made of carbon fiber reinforced fabric reinforced vulcanized rubber, formed by a metal male-female combination mold, and its cross-section is consistent with the inner surface of the Ω stringer; the airbag includes an outer Unvulcanized rubber layer 4, R-angle reinforced fiber 5, carbon fiber reinforced fabric 6, inner unvulcanized rubber layer 7 and vacuum bag 8; the outermost layer of the airbag is the outer unvulcanized rubber layer 4, and its cross-section is consistent with the inner profile of the Ω stringer ; At the position of the R angle of the airbag, that is, at the edge of the inner wall of the outer unvulcanized rubber layer 4, an R-angle reinforcing fiber 5 is pasted to ensure that the airbag and the inner surface of the Ω stringer fit together; the inner unvulcanized rubber layer 7 is located at the outer unvulcanized rubber layer In the layer 4, a layer of ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com