An airtight door and its seal structure

A technology for sealing parts and airtight doors, applied in the field of airtight doors, can solve the problems of complicated processing technology, easy wrinkling, deformation and falling off, and unsatisfactory airtight effect at the corners of the bowl-shaped bell mouth sealing strip, and achieves easy standardization. Production, good economic benefits, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

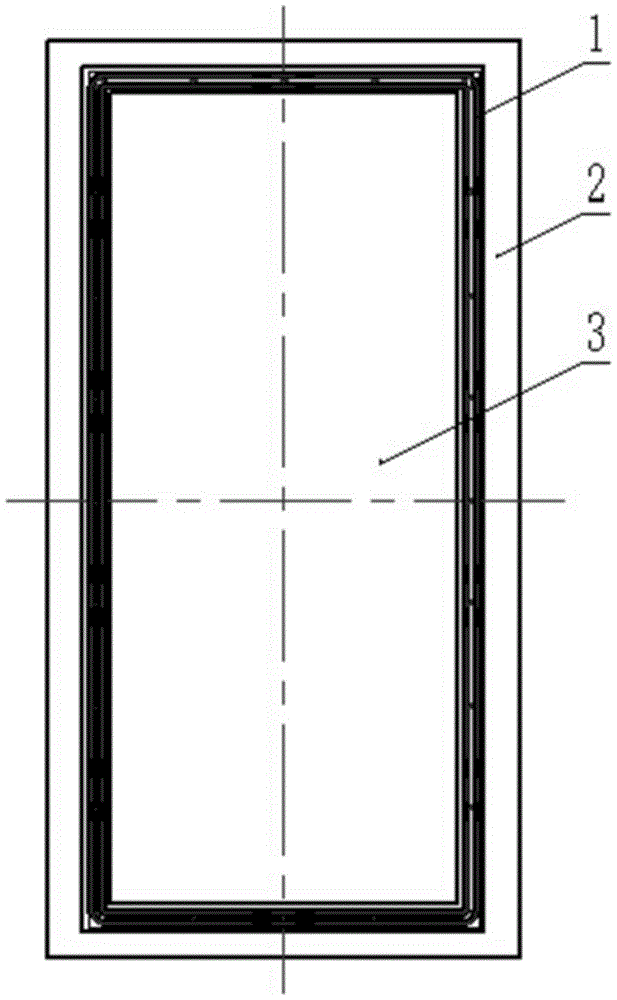

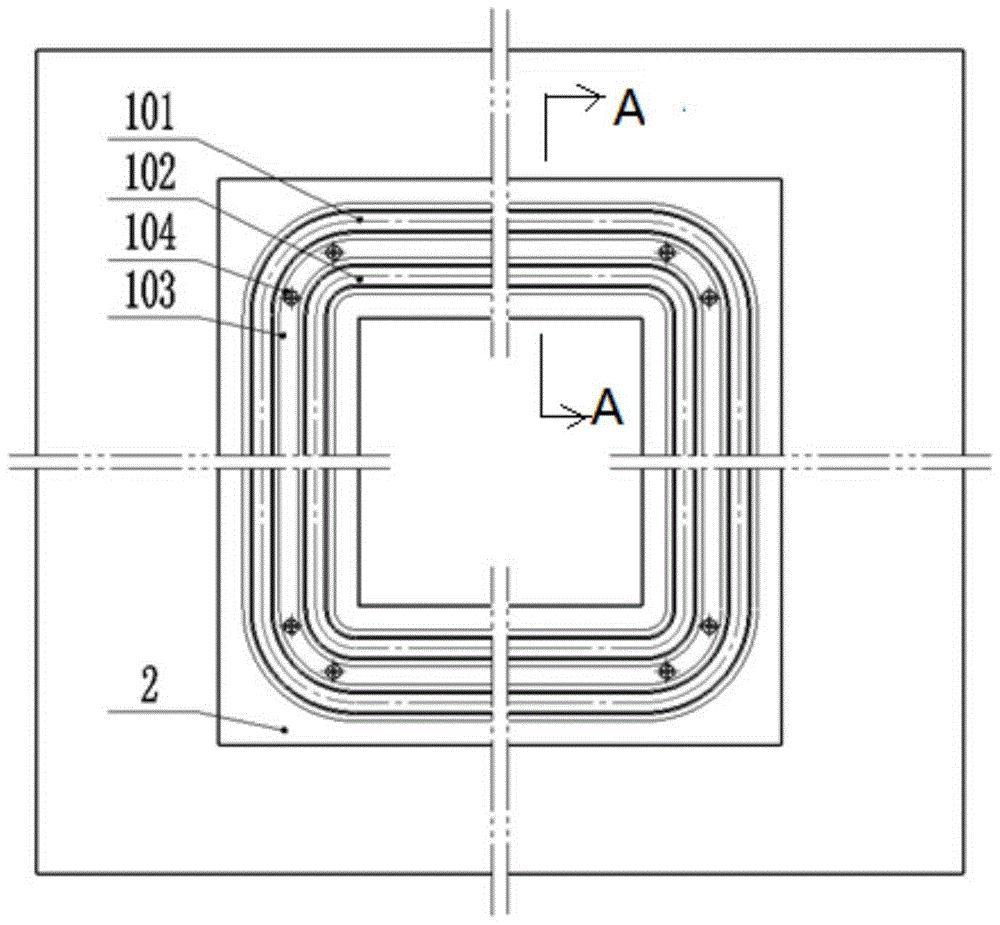

[0022] join Figure 1-Figure 3 , an airtight door seal structure, including a seal structure 1, a door frame 2, and a door leaf 3, the seal structure 1 is installed on the door frame 2; the seal structure includes an outer seal ring 101, an inner seal ring 102, Seal groove seat 103, screw 104; Described seal groove seat 103 has the seal groove of detachable assembly outer seal ring and inner seal ring simultaneously, and is fixed on the door frame 2 by screw 104; Outer seal ring 101 and inner seal ring 102 are both It is a hollow structure; the outer sealing ring 101 and the inner sealing ring 102 are compressed by the door frame 2 and the door leaf 3 to achieve a sealing effect.

[0023] The joints of the two ends of the outer seal ring 101 and the inner seal ring 102 are glued with oblique joints.

[0024] The sealing groove seat 103 is formed by sheet metal bending processing, and the seams are fully welded to form an integral structure.

[0025] The sealing groove seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com