Suction sewage truck for railway ballast bed

A technology for sewage suction vehicles and track beds, which is used in track cleaning, construction, cleaning methods, etc., can solve the problems of limited track suction width, reduced sewage suction capacity, large distance, etc., to improve space utilization and dynamic performance. The effect of improving dirt absorption performance and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the drawings.

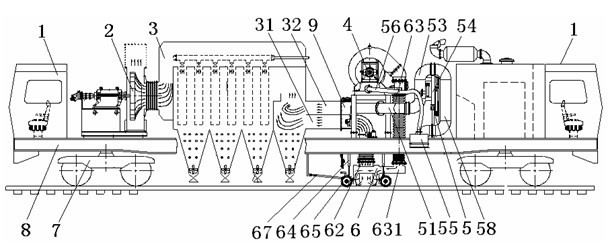

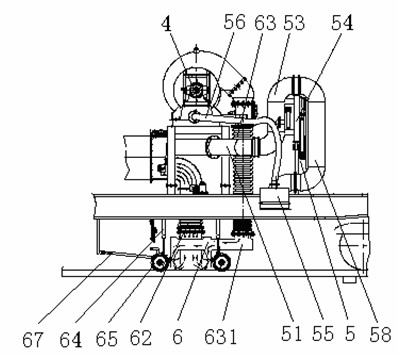

[0029] The railway track bed sewage suction vehicle provided by the present invention includes a bogie 7 underneath, a cab 1, a conventional dust collector 3 and an exhaust fan 2, and a conventional blower 4 frame 8 on the frame 8. There are a lifting type railway track bed pollution blowing and suction device 6 connected with the dust collector 3 and a railway track bed side pollution blowing and suction device 5, of which:

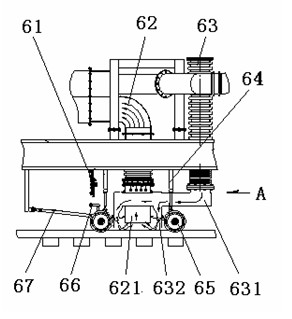

[0030] The lifting type railway track bed blowing and suction device 6 includes a suction bellows 62 connected to the inlet 31 of the dust collector 3 through a damper 9, a blowing bellows 63 connected to the blower 4, and a lifting cylinder 64 connected to the train On the lower side of the frame 8 there is a movable frame 66 with guide wheels 65 on it. The movable frame 66 is provided with a blow box 632 whose upper end is connected to the blowing bellows 62 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com