Technical method for manufacturing artificial boards with peanut shells and sunflower stalks by pressing

A technology of peanut shells and sunflower stalks, which is applied in the technical field of pressing wood-based panels with peanut shells and sunflower stalks, can solve the problems of high production cost, heavy use, and limited production, and achieve reduction of raw material costs, improvement of internal bonding force, and simplification of the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

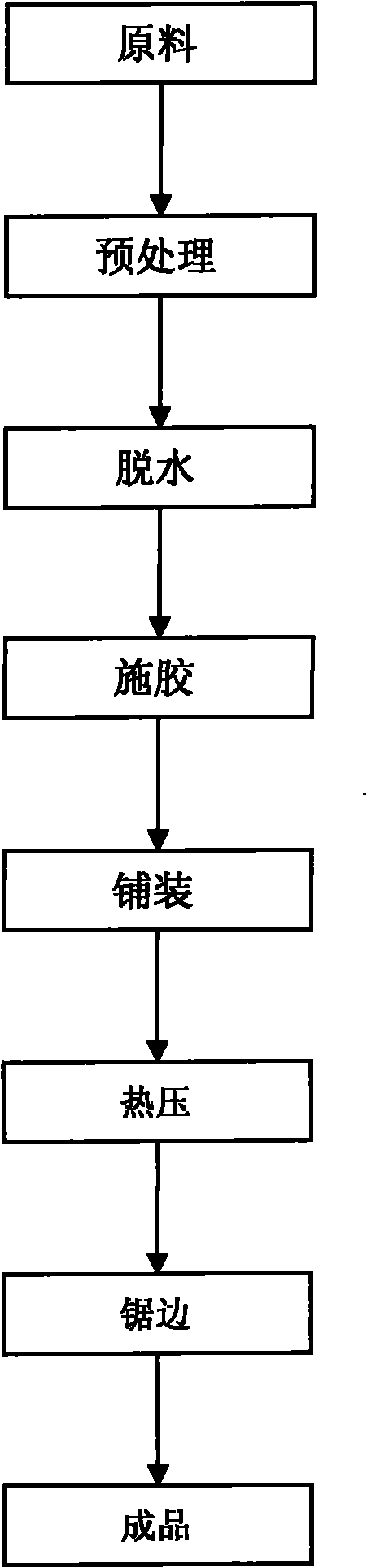

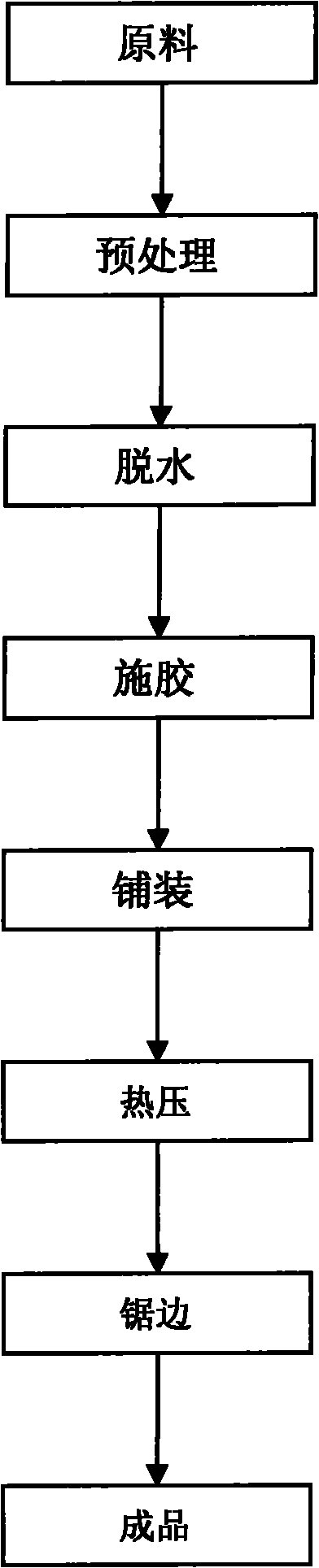

Method used

Image

Examples

Embodiment 1

[0017] First, crush the peanut shells into a flat sheet, break the sunflower stalks from the middle, remove the skin core, then dry or air-dry to make the water content <6%, and then enter the sizing process; the peanut shells Pour it into the glue mixing machine for sizing, spray the sunflower stalks with a glue gun, and spray the wood skin with a glue gun or brush it by hand. The glue is made of urea-formaldehyde resin glue with a solid content of 60%. The amount of sizing is 10% of the weight ratio of raw materials, and then it enters the paving process; firstly, the wooden skin after sizing is laid on the aluminum formwork, and then the peanut shells are laid, each layer is 20mm thick, and then the sunflower stalks are pressed on the same Lay the peanut shells vertically in parallel, then lay the second layer of peanut shells, the layer thickness is also 20mm, then lay the second layer of sunflower stalks horizontally in the same direction, and then lay the third layer of p...

Embodiment 2

[0019] Peanut shells are rolled, sunflower stalks are dried or air-dried after removing the skin core, and the moisture content is less than 6%. After the peanut shells and sunflower stalk wood skins are glued, they enter the paving process; first, the wood skins are laid on the aluminum formwork Then put the peanut shells on the wooden surface with a layer thickness of 15mm, then lay the sunflower stalks in the same direction, parallel and vertically lay them on the peanut shells, and then lay the second layer of peanut shells, the layer thickness is also 15mm, Then lay the sunflower stalks on the peanut shells in parallel and horizontally in the same direction, that is, one layer of peanut shells and one layer of sunflower stalks to form a criss-cross multi-layer structure. Repeated laying of 6 layers can press out 2440mm×1220mm×10mm Length×width×thick board, other process conditions are the same as embodiment 1, can produce qualified man-made board likewise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com