Milling cutter

A technology of milling cutter and cutter head, applied in the field of milling cutter, can solve the problem that the chip removal effect of the milling cutter is not very good, and achieve the effect of good chip removal effect, large feed rate and light cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

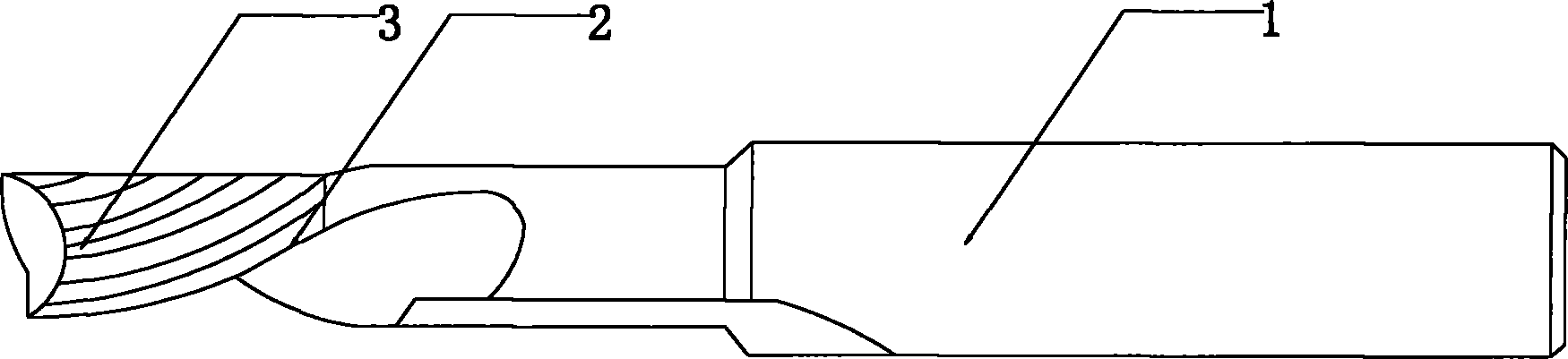

[0011] Such as figure 1 As shown, a milling cutter includes a tool handle 1 and a cutter head 2, and the cutter head 2 is designed as a hollow spiral structure, so that when high-speed cutting and high feed rate, a large amount of iron filings from the hollow cutter head 2 Discharge, the spiral structure can accelerate the discharge of iron filings. In order to further fully discharge the iron filings, a plurality of spiral grooves 3 are provided on the surface of the cutter head 2. The shape of each groove 3 is consistent with the spiral shape of the cutter head 2. The shapes are roughly the same, and each groove 3 can guide the discharge of iron filings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com