Heater of oil diffusion pump

A technology for oil diffusion pumps and heaters, applied in the direction of diffusion pumps, heating element shapes, pumps, etc., can solve the problems of the end of the life of the heating plate, large stress and deformation force, and short service life of the resistance wire, so as to reduce the probability of high temperature deformation, Effect of lowering surface temperature and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

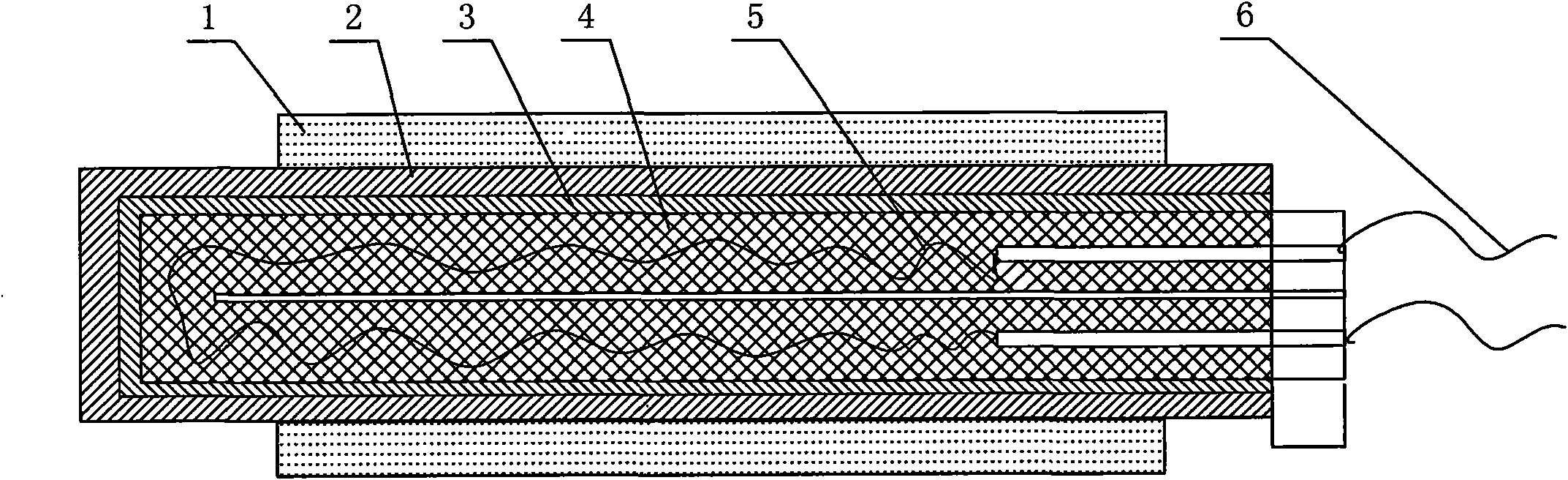

[0010] The structure of the present invention is as follows: the present invention includes a sleeve 2 and an electric heating tube arranged in the sleeve 2 and in close contact with the sleeve 2 , the electric heating tube extends from the sleeve 2 and is externally connected to a power line 6 .

[0011] The electric heating tube of the present invention is preferably a split sheath type, and its structure is U-shaped. 5 The free end is connected to the power line 6, and a magnesium oxide insulating layer 4 is provided between the heating wire 5 and the heat conduction shell 3.

[0012] In the present invention, a cooling strip 1 in contact with the sleeve 2 is further arranged outside the sleeve 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com