Anti-dazzling film, production method of anti-dazzling film, polarizing plate using anti-dazzling film and display device with polarizing plate

A technology of anti-glare film and polarizing plate, which is applied in the direction of optics, polarizing elements, optical elements, etc., can solve the problems of high haze value, low light transmittance, and low hardness of anti-glare film, and achieve high anti-glare performance and high transmittance. High light rate, good hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

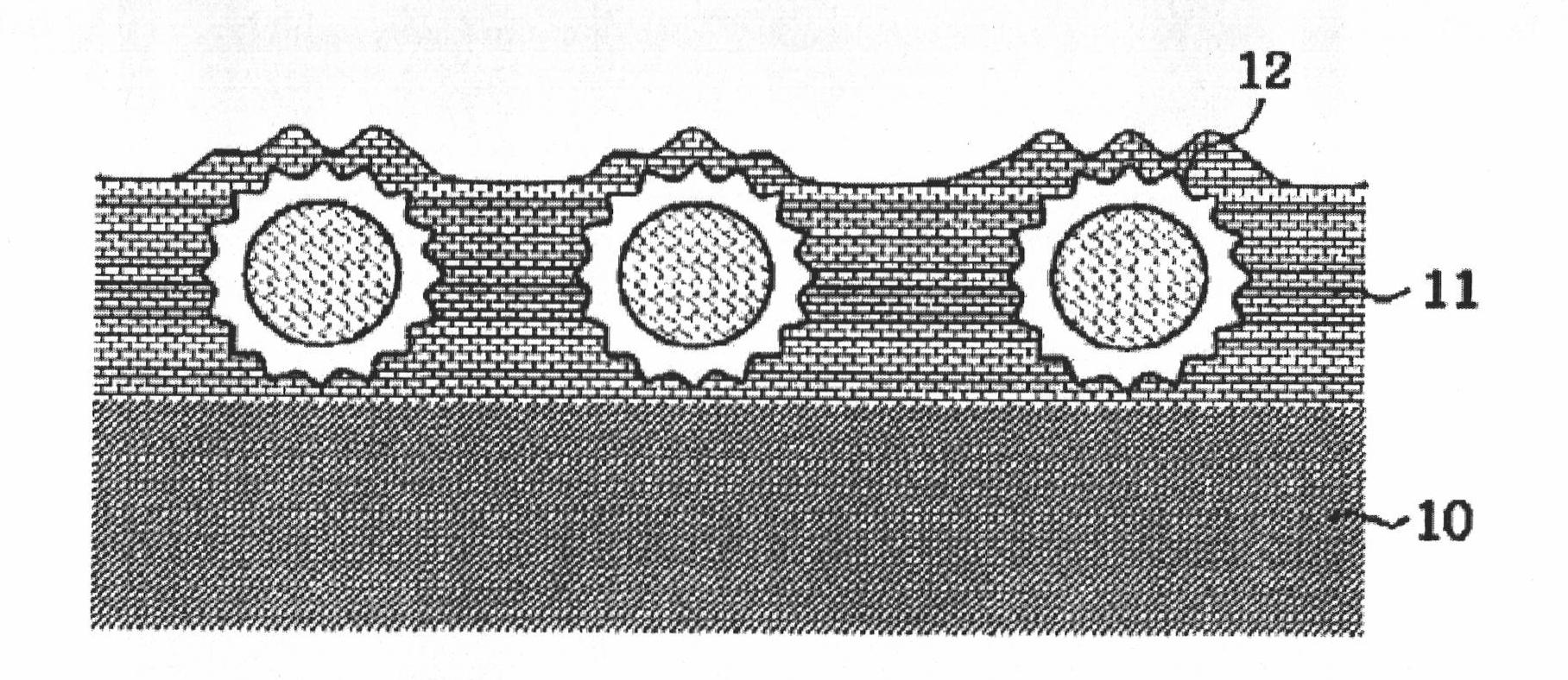

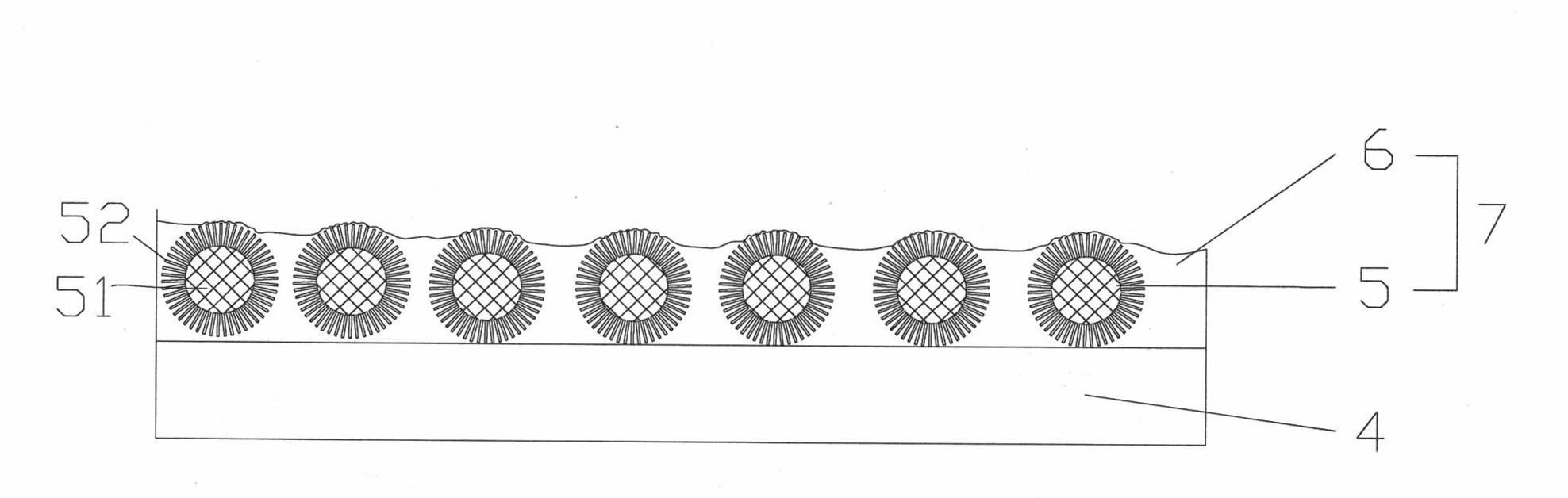

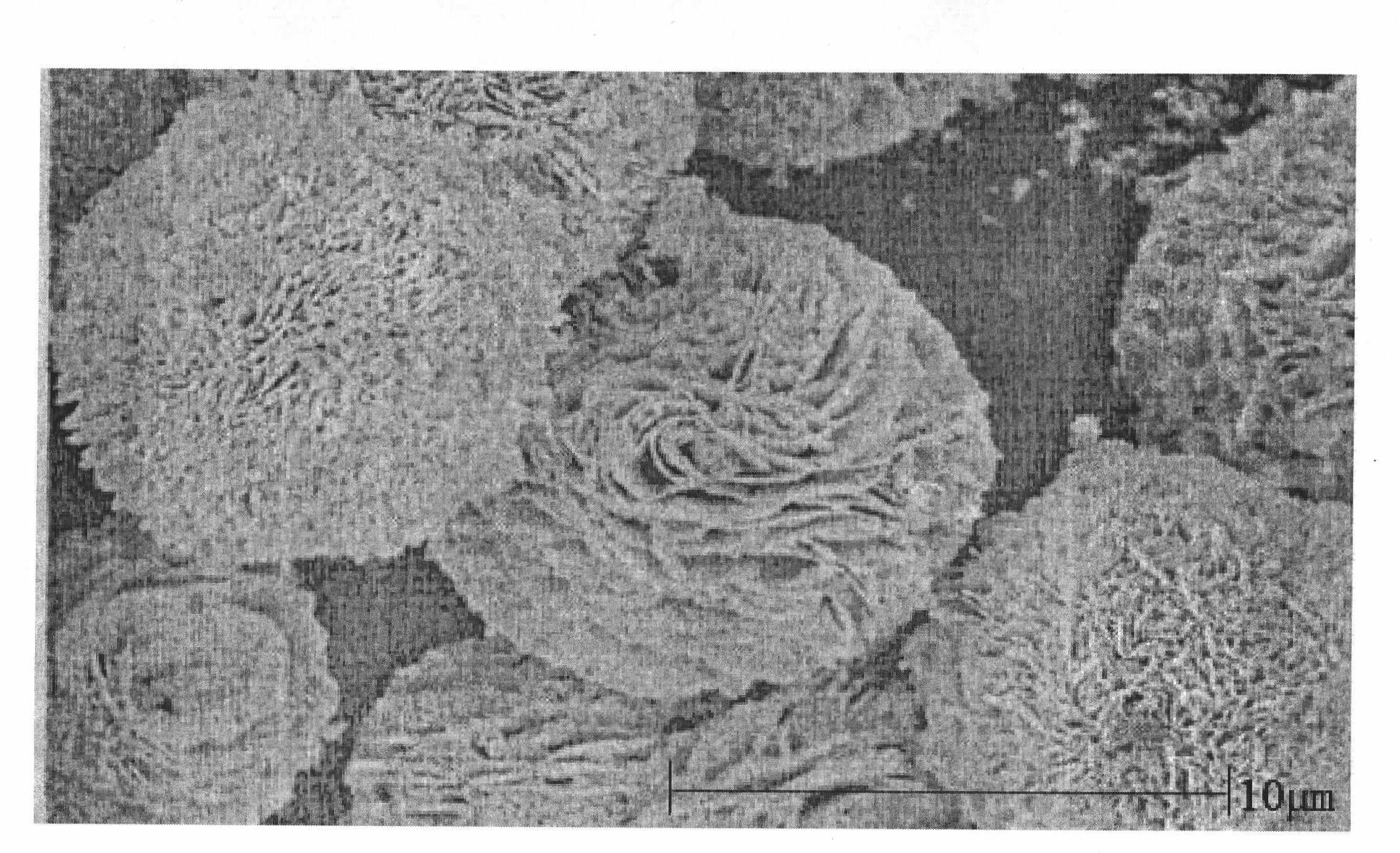

[0044] Step 1, preparing flower spherical particles.

[0045] The curd-shaped particles of the present embodiment are curd-shaped nickel oxide microspheres, which are made of macrocyclic polyamine (hexamethyl-1, 4, 8, 11-tetraazacyclo 14-4, 11-diene) using methanol, ethanol Diamine, hydrobromic acid, and acetone are raw materials, which are synthesized by chemical methods. The specific preparation method is as follows:

[0046] ① Weigh 5.0g of macrocyclic polyamine and dissolve it in 30mL of water, add 10g of basic nickel carbonate, and heat the mixture in a water bath for 30min;

[0047] 2. filter out unreacted basic nickel carbonate, and the obtained macrocyclic polyamine-nickel complex filtrate is standby;

[0048] ③Take 27mL of macrocyclic polyamine-nickel complex filtrate, dilute it with 13mL of twice distilled water, put it into a 50mL stainless steel kettle lined with polytetrafluoroethylene, put it in a temperature-programmed furnace, and react at 180°C for 24h;

[0...

Embodiment 2

[0062] With other conditions unchanged, the calcination temperature in step 5 of preparing the flower-shaped nickel oxide microspheres was increased to 6h, and the average particle diameter of the flower-shaped nickel oxide microspheres obtained was 4 μm, the height of the petals was 0.3 μm, and the width of the internal reticular voids was 0.25 μm, and the thickness of the anti-glare coating is 4.7 μm.

Embodiment 3

[0066] Other conditions remain the same, the calcination temperature in step 5 of the preparation of flower-shaped nickel oxide microspheres is increased to 8h, and the average particle diameter of flower-shaped nickel oxide microspheres obtained is 7 μm, the height of petals is 0.61 μm, and the width of internal reticular voids is 0.3 μm, and the thickness of the anti-glare coating is 7.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com