Hot-water type dynamic-regulating type steam-water direct-mixing type heat-exchanging device

A heat exchange device and dynamic adjustment technology, applied in the field of heat exchange, can solve the problems of inability to continuously adjust the state of the mixture, reducing heat exchange efficiency and operating safety, etc.

Inactive Publication Date: 2013-04-24

LUOYANG BLUE SEA INDAL

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Even when there are slight changes in heat load or operating parameters, it is impossible to continuously adjust the mixture state under a certain influent flow rate, so that the system operates in a non-optimal operating state, reducing heat transfer efficiency and operating safety

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

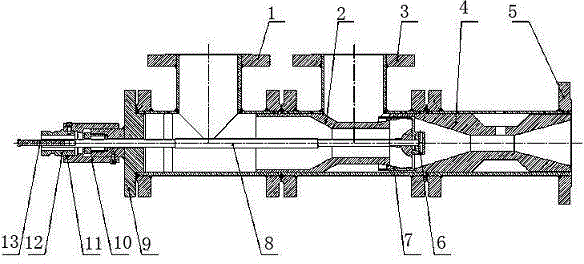

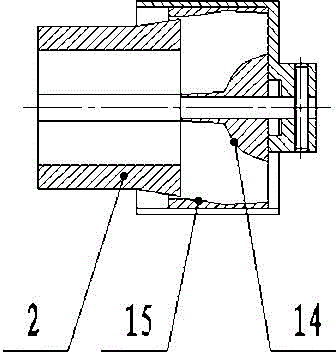

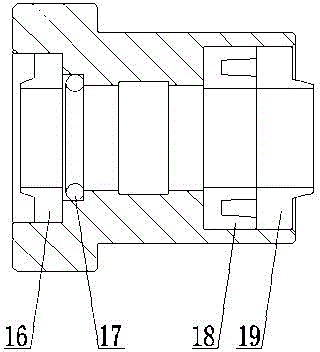

The invention belongs to a hot-water type dynamic-regulating type steam-water direct-mixing type heat-exchanging device, which comprises a front three-way pipe (1), a front core (2), a middle three-way pipe (3), a middle core (4), a long two-way pipe (5), a temperature sensor, an electric executing mechanism and a controller, wherein the front core (2) is coaxially arranged in the middle three-way pipe (3), the middle core (4) is nested between the middle three-way pipe (3) and the long two-way pipe (5), a regulating device (7) is arranged between the front core and the middle core, the regulating device can make axial forward and backward horizontal movement under the driving of the electric executing mechanism, the regulating device is formed from a water-direction regulating surface (14) and a steam-direction regulating surface (15), the magnitude of the steam quantity is controlled by adjusting a variable sectional area formed from the steam-direction regulating surface and the inner wall surface of a front-core nozzle, and the magnitude of the inlet-water quantity is controlled by adjusting the variable sectional area formed from the water-direction regulating surface and theouter wall surface of the front-core nozzle. When the steam parameter of a user is changed, the purpose of continuous and dynamic regulation is achieved under the condition that the operation of a system is not stopped.

Description

technical field [0001] The invention belongs to the technical field of heat exchange, and mainly relates to a hot water type dynamic regulation steam-water direct mixing heat exchanger. Background technique [0002] The domestic known steam-water direct mixing heat exchanger can only adjust the flow and temperature intermittently. When the heat load of the heat exchanger changes, or the parameters of steam and supply and return water change and the system affects the normal operation, it cannot be adjusted immediately. Cause the water temperature fluctuation range is too large, the rate of change is too fast. If adjustment is required, the current method is to stop the system, disassemble the equipment as a whole, and adjust the internal structure of the product to meet the requirements of use. Even when the thermal load or operating parameters change slightly, it is impossible to continuously adjust the state of the mixture under a certain influent flow rate, so that the s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F28C3/08F28F27/00

Inventor 曹辉王龙江张嘉孙晓琳吴小天罗明才

Owner LUOYANG BLUE SEA INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com