Pneumatic frictional heating water heater

A friction heating and hot water technology, which is applied to household heating, heating methods, heating systems, etc., can solve problems such as unusable water heaters, save energy, facilitate maintenance, and improve indoor temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

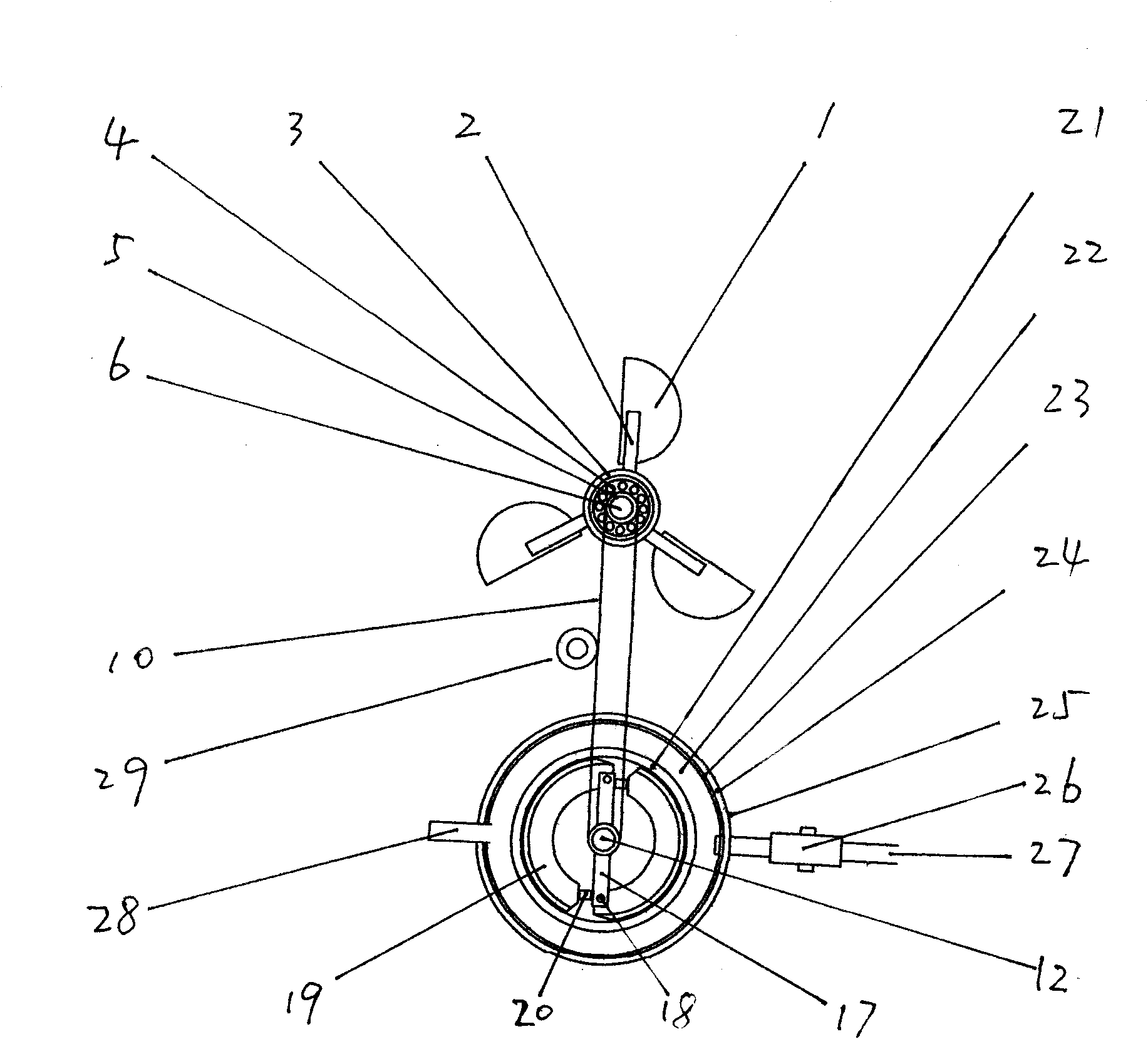

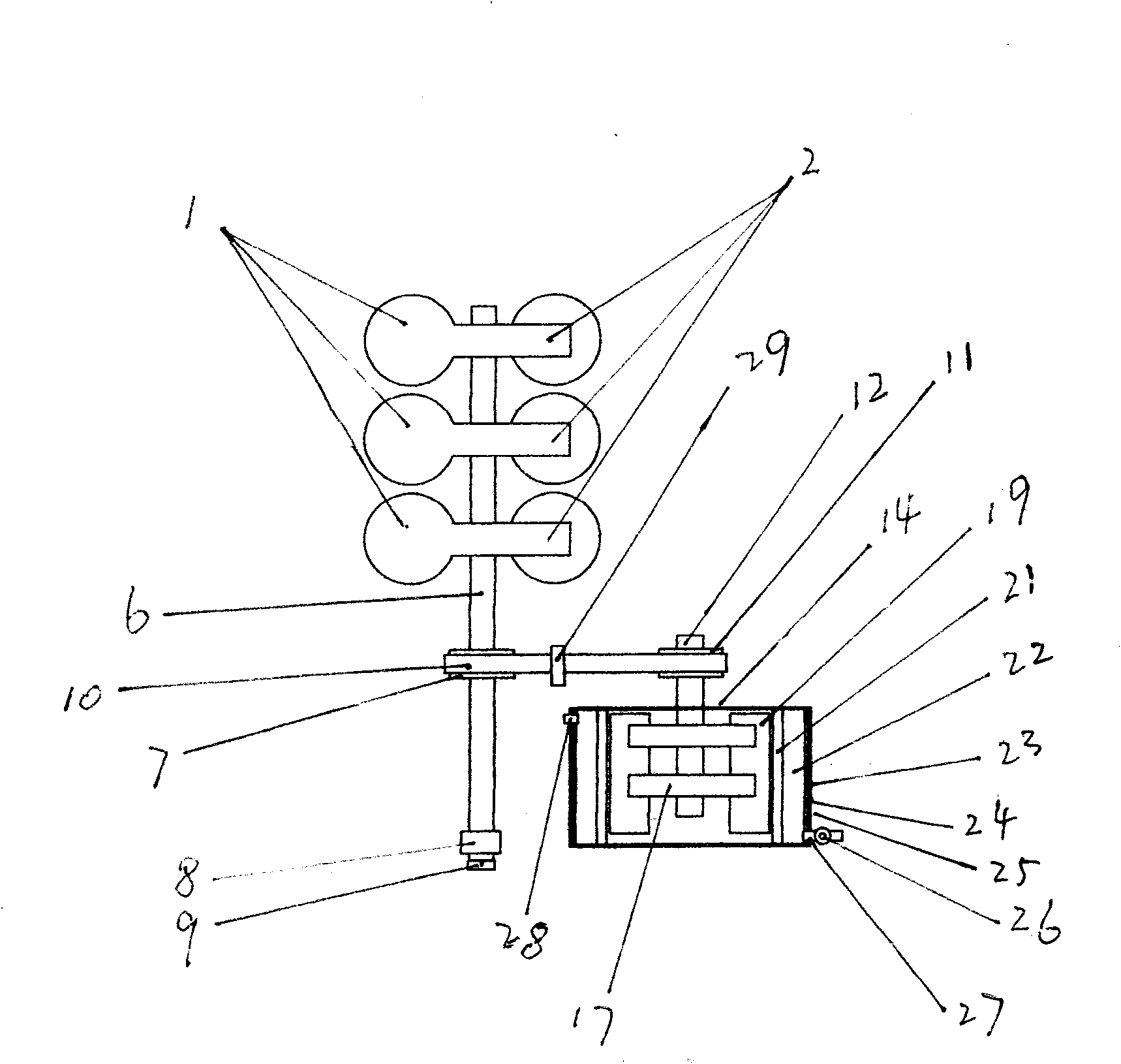

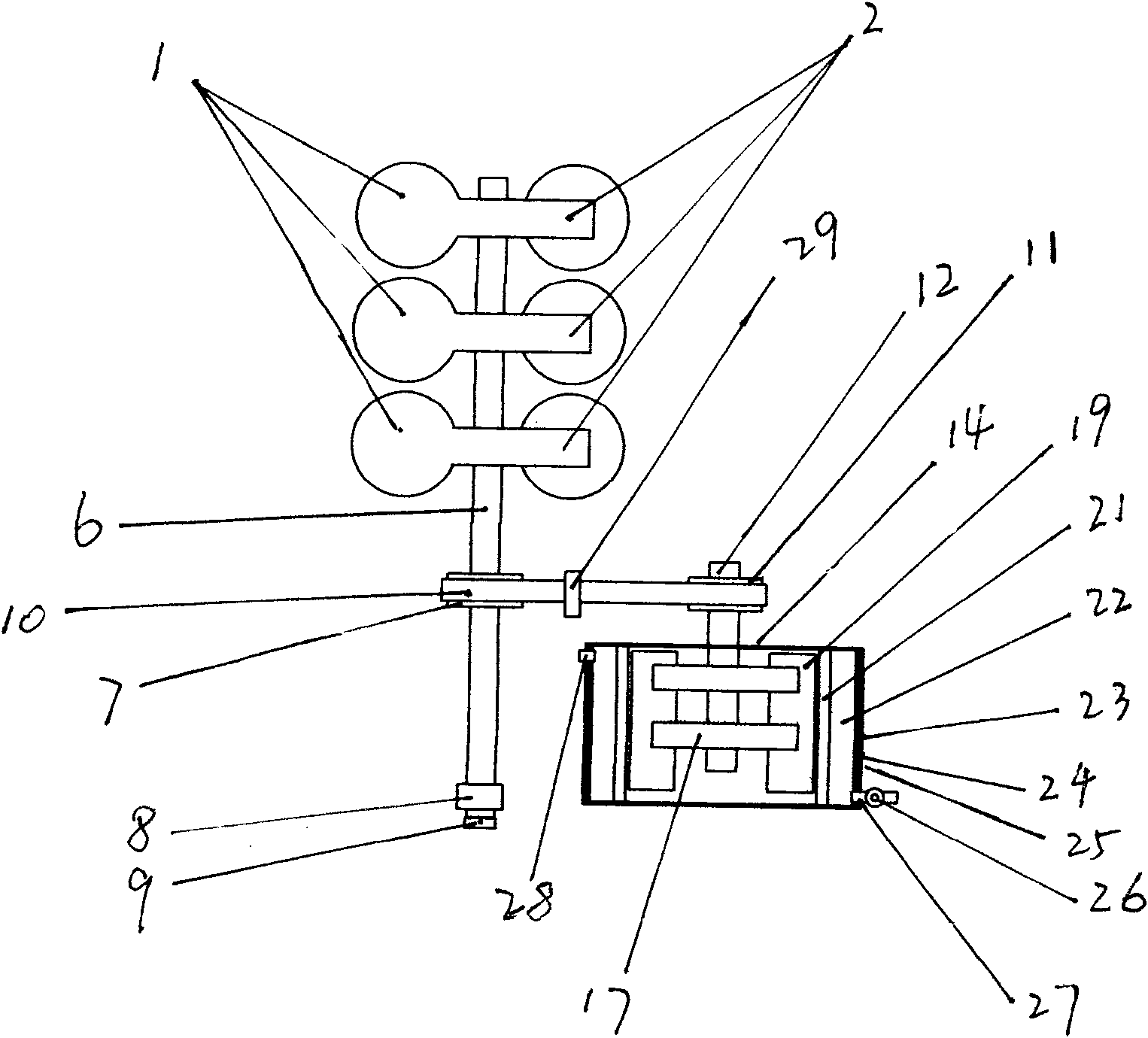

[0020] Fig. 1 is a perspective state of a top view of the present invention. Wind collection device as shown in Figure 1: using three hollow hemispherical wind buckets (1), under the action of connecting rod (2), bearing sleeve (3), bearing (4), and bearing tensioner sleeve (5) , to form a wind collection disk. It is characterized in that: the wind bucket (1) on the wind collection disk generates rotational power when the wind blows. This power can drive the transmission shaft in the middle of the wind collecting disk to rotate together. The wind collecting discs can overlap three or more layers, so as to increase the amount of wind collecting and increase the driving force of the transmission shaft rotation.

[0021] The bearing tensioner sleeve (5) in the middle of the wind collecting disk of the present invention. It is characterized in that: the wind collecting disk bearing (4) is tightly connected to the transmission shaft. The wind-collecting disk is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com