Center rocket type bimodal ramjet with circular structure

A ramjet and rocket-type technology, which is applied in the direction of rocket engine devices, ramjet engines, machines/engines, etc., can solve the problems of restricting the application of large-scale engines, small flame stability area, unfavorable processing and manufacturing, etc., to solve the problem of fuel Penetration and blending problems, safe and reliable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

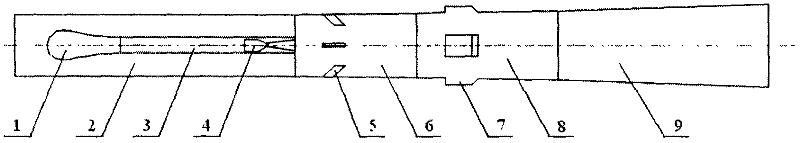

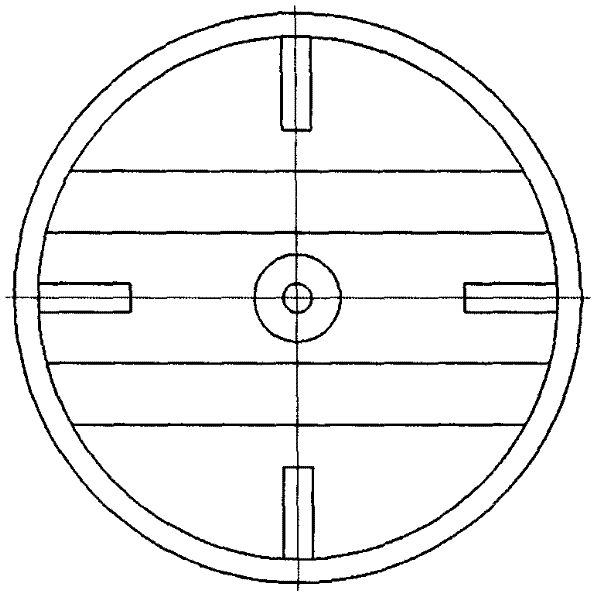

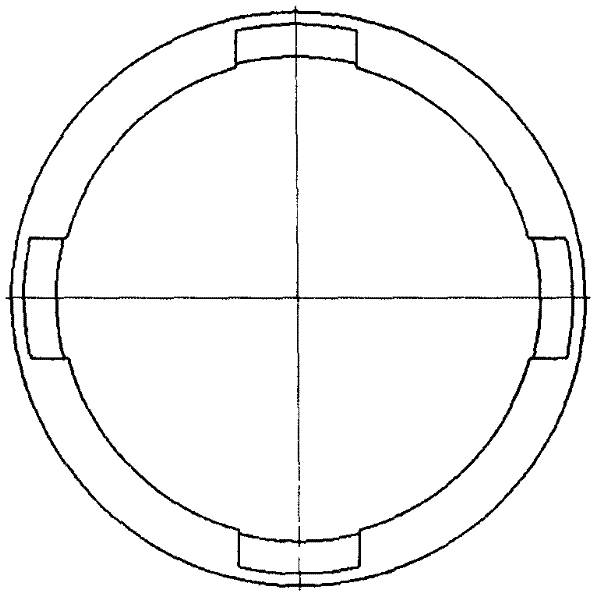

[0020] This embodiment is a center rocket dual-mode ramjet with a circular structure. The dual-mode ramjet includes an equipment nozzle 1, an isolation section 2, a main support plate 3, a central rocket 4, a small support plate 5, a first-stage combustion chamber 6, a cavity 7, a second-stage combustion chamber 8, and an expansion section 9.

[0021] figure 1 The structure of the dual-mode ramjet is shown. The isolation section 2, the first-stage combustion chamber 6, the second-stage combustion chamber 8, and the expansion section 9 are threaded through, and the cross-sections are circular structures; the equipment nozzle 1 is installed in the isolation Before segment 2, it is used to simulate the compression effect of the intake port in a real engine. The main support plate 3 is arranged in the isolation section 2. In order to ensure the symmetry of the flow field, it penetrates up and down along the symmetry plane of the isolation section 2; the central rocket 4 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com