Intermediate hinged shaft device for medium-low speed maglev turnout junction girder

The technology of turnout beam and hinge shaft is applied in the field of turnout design of medium and low-speed maglev traffic system, which can solve the problems of inability to withstand vertical force, insufficient rigidity of the beam body, and unrestricted vertical upward degree of freedom, etc., and achieves convenient installation and adjustment. Novel and unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

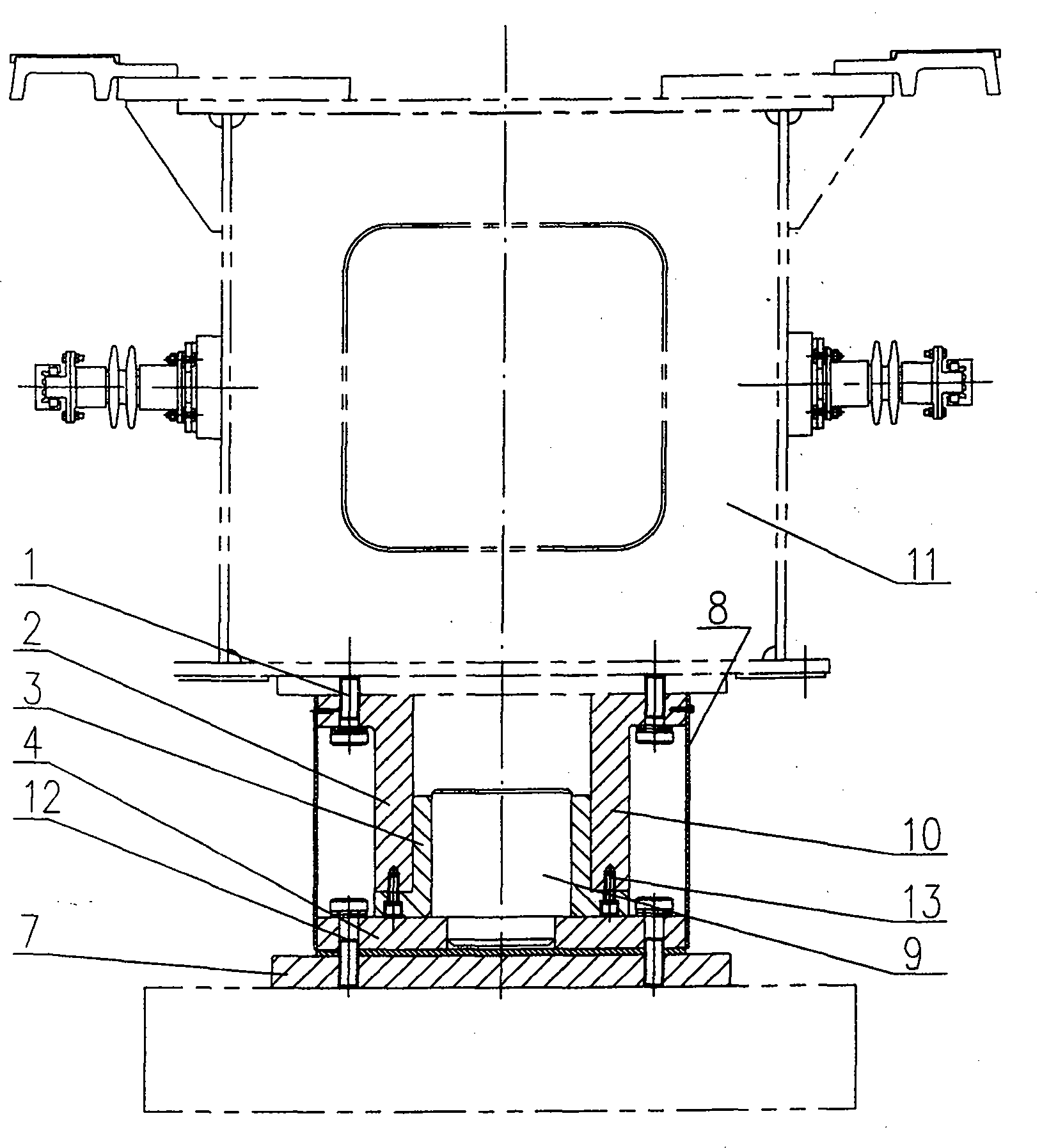

[0013] Attached below figure 1 An embodiment of the present invention is described.

[0014] An intermediate hinge shaft device for a medium-low speed maglev turnout beam, comprising a lower pressure bearing plate 7 , a hinge shaft 9 and an upper pressure bearing sleeve 10 . The upper pressure bearing sleeve 10 is composed of an upper shaft sleeve 2 and a high-strength brass sleeve 3 . A hinge shaft support 4 is fixed above the lower pressure bearing plate 7 by bolts II 12 , and the lower end of the hinge shaft 9 is inserted on the hinge shaft support 4 . The upper end of the hinge shaft 9 is covered with a high-strength brass bushing 3, and the high-strength brass bushing 3 is covered with an upper bushing 2, and the high-strength brass bushing 3 is fixedly connected with the upper bushing 2 as a whole. The upper end of the upper bushing 2 is fixedly connected with the turnout beam 11 through the bolt III1. A protective cover 8 is installed on the upper shaft sleeve 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com