Gas self-production agent, use of the gas self-production agent, and self-produced gas foam acidizing method for oil wells and water wells

A foam acidification, self-producing gas technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of complex procedures and high production costs, and achieve simplified construction procedures, low construction costs, and suitable Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

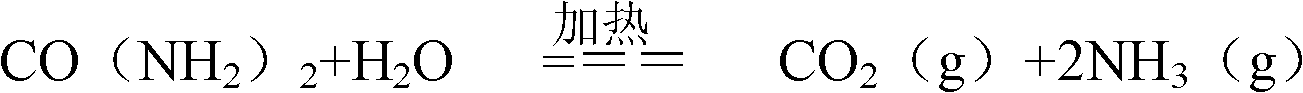

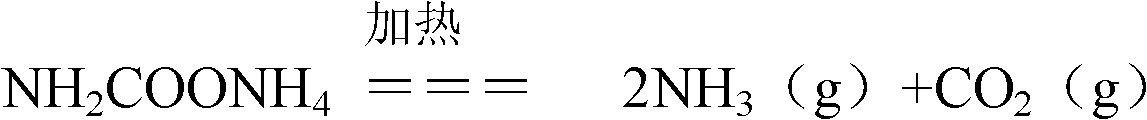

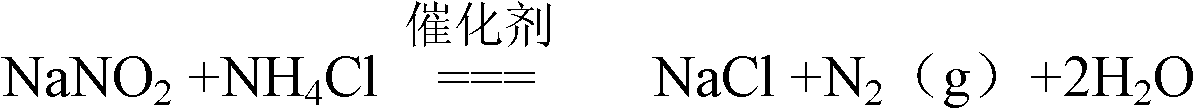

[0034] Self-generating gas agent, which generates gas when encountering acid or at the formation temperature of oil wells, and its active ingredient is ammonium carbamate.

[0035] The gas production performance of this self-generating agent is measured as follows:

[0036] The gas measuring device consists of a 200ml alkaline burette, a level bottle, a density bottle (50ml), a thermal fluid and an electric heating jacket. The density bottle holds the self-generating agent solution, and the bottle stopper is connected to the burette through the air guide tube. When the temperature of the density bottle reaches 60°C, connect it to the burette, and when the gas generation time reaches 5 minutes, close the connecting valve between the two, and read the ml of gas generated when the liquid level of the level bottle is at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com