System for manufacturing multi-component high molecular polymer fiber sound-absorbing heat-insulating material

A high-molecular polymer and thermal insulation material technology, which is applied in the field of manufacturing systems for multi-component polymer fiber sound-absorbing thermal insulation materials, can solve problems such as performance barriers, tensile decline, and discounted sound-absorbing performance of sound-absorbing thermal insulation materials, and achieve The clear effect of the structural principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

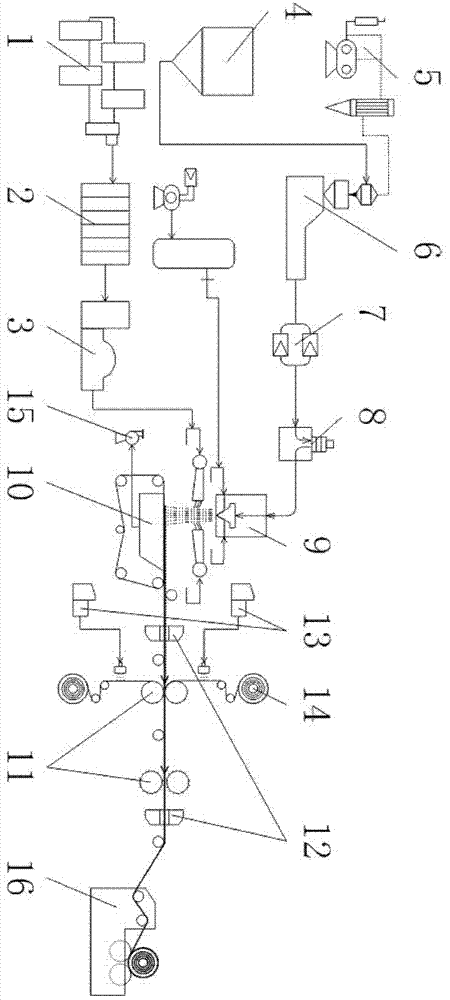

[0013] Embodiment: With reference to accompanying drawing, the manufacturing system of multi-component polymer fiber sound-absorbing and thermal insulation material, comprises short fiber mixed carding device, melt-blown mixed forming device, surface strengthening treatment device and winding machine 16, short fiber mixed carding device Including automatic feeding weighing machine 1, multi-bin mixing machine 2 and carding machine 3, the conveyor belt of automatic feeding weighing machine 1 extends into the feeding port of multi-bin mixing machine 2, and the outlet of multi-bin mixing machine 2 The feed port is connected to the carding machine 3, and the melt-blown mixing and forming device includes a raw material bin 4, a vacuum pump 5, an extruder 6, a melt filter 7, a gear pump 8 and a melt-blown die head 9, and the extruder 6 is connected with a raw material There is a vacuum pump 5 between the warehouse 4, the raw material warehouse 4 and the extruder 6, and the extruder 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com