Non-woven fabric and manufacturing method thereof

A manufacturing method and technology for non-woven fabrics, which are used in textiles and papermaking, layered products, fiber processing, etc., can solve the problems of reducing water pressure resistance, humidity buffering performance, and difficulty in realizing differential transfer of liquid water in non-woven fabrics. Improved water pressure resistance, improved water pressure resistance, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Select single cellulose fiber to produce non-woven fabric with spunlace process in the present embodiment, cloth weight 60g / m 2 .

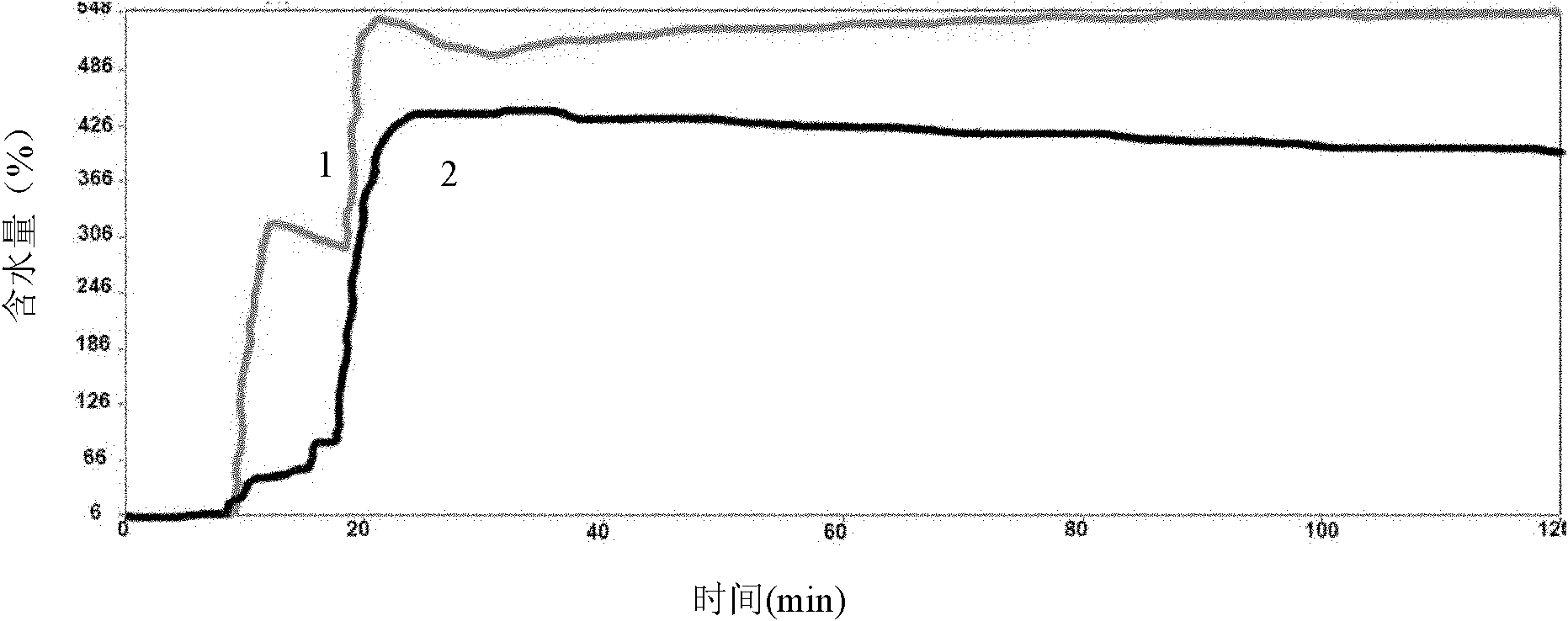

[0056] Measure the differential water conductivity of non-woven fabrics according to the standard SNT1689-2005, see the test results figure 2 , figure 2 It shows the change with time of the water content of the upper and lower surfaces of the nonwoven fabric. In the figure, curve 1 represents the change of water content on the upper surface of the nonwoven fabric, and curve 2 represents the change of water content on the lower surface of the nonwoven fabric. Depend on figure 2 It can be seen that the non-woven fabric is a kind of hydrophilic non-woven fabric. When the water reaches the upper surface of the non-woven fabric, the water diffuses and penetrates on both surfaces. The water content of the two surfaces is basically the same. The water content is slightly higher than the lower surface.

[0057] Use the spraying method to ca...

Embodiment 2

[0073] The non-woven fabric with a two-layer structure is produced by the needle punching method: the bottom layer is fed with hydrophilic polyester staple fibers with special-shaped cross-sections, which are laid out after carding, and the upper layer is covered with a layer of hydrophobic polypropylene staple fibers (also laid out after feeding and carding). Intertanglement and reinforcement of fibers is achieved by needling. The thickness of the hydrophobic layer of the obtained nonwoven fabric was about 0.5 mm, and the thickness of the hydrophilic layer was about 0.1 mm. After testing, it was found that the increase in the thickness of the hydrophilic layer made the effect of differential water conduction more obvious.

Embodiment 3

[0075] First, the hydrophobic polypropylene staple fiber is functionally finished, and then the nonwoven fabric is manufactured according to the method in Example 2. Functional finishing of hydrophobic polypropylene staple fiber:

[0076] I. Preparing Auxiliaries

[0077] A.WRSC35 (Hong Kong Advanced (Group) Co., Ltd.) 60g / L

[0078] B. Nano protein material (self-made according to the prior patent) 8g / L

[0079] C. Chitosan (Tokyo Chemical Industry Co., Ltd.) 2g / L

[0080] D. Thickener FS-80 (Dandong Star Fine Chemical Co., Ltd.) 5g / L

[0081] E. Cross-linking agent PU-DS70 (Dongguan Tongsen Chemical Co., Ltd., Guangdong Province) 5g / L

[0082] F. Other water;

[0083] II. Spraying

[0084] A. Spray volume: 20g / m 2 ;

[0085] B. Drying: 120°C for 2 minutes, 140°C for 1.5 minutes.

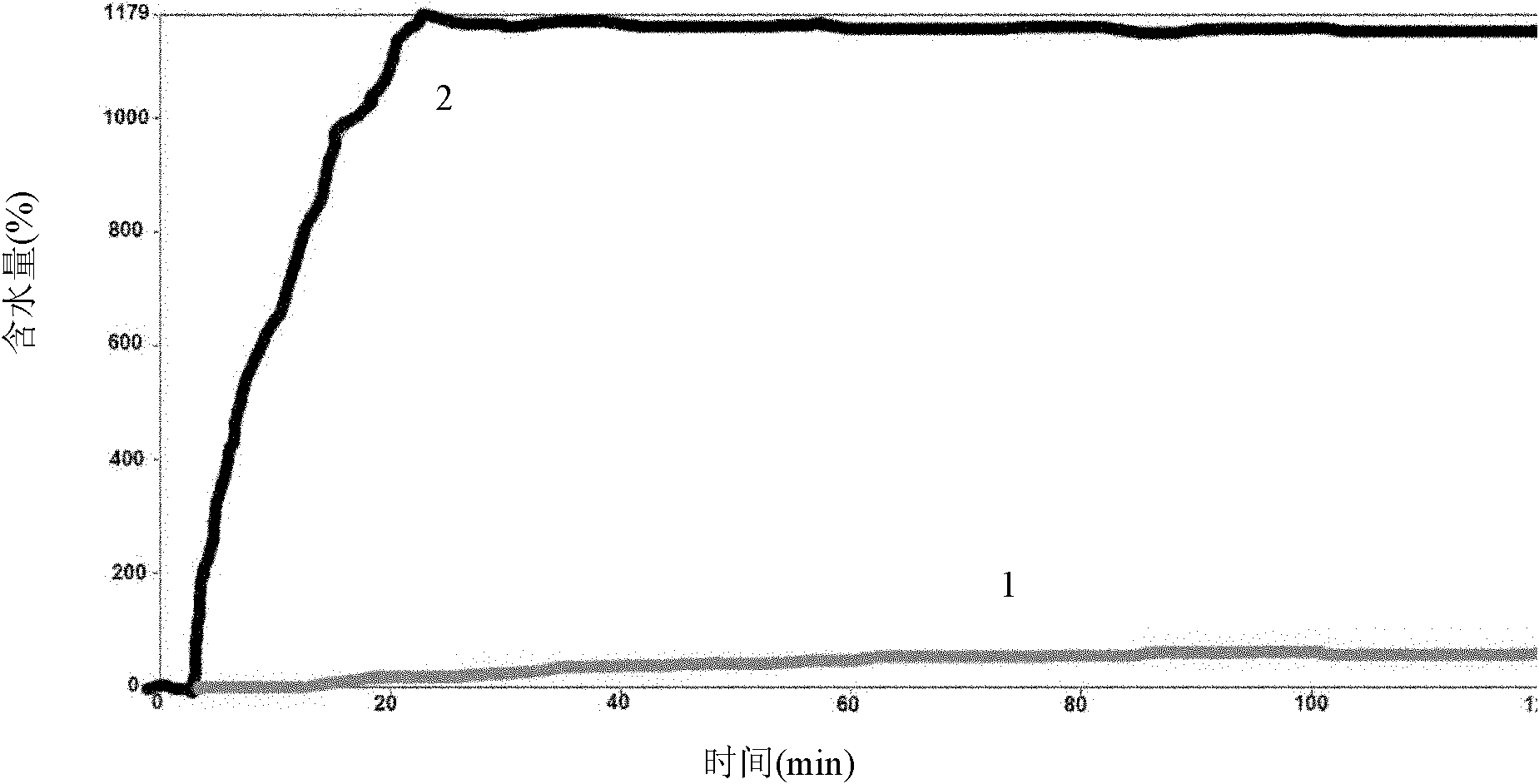

[0086] Figure 9 It is the comparison chart of moisture regain before and after finishing the non-woven fabric hydrophobic layer of this embodiment, as Figure 9 As shown, the moisture r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com