Brewery facility for producing and bottling beer

A technology for filling equipment and equipment, which is used in beer brewing, lighting and heating equipment, biochemical equipment and methods, etc., and can solve problems such as high energy density that cannot reach the maximum temperature level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

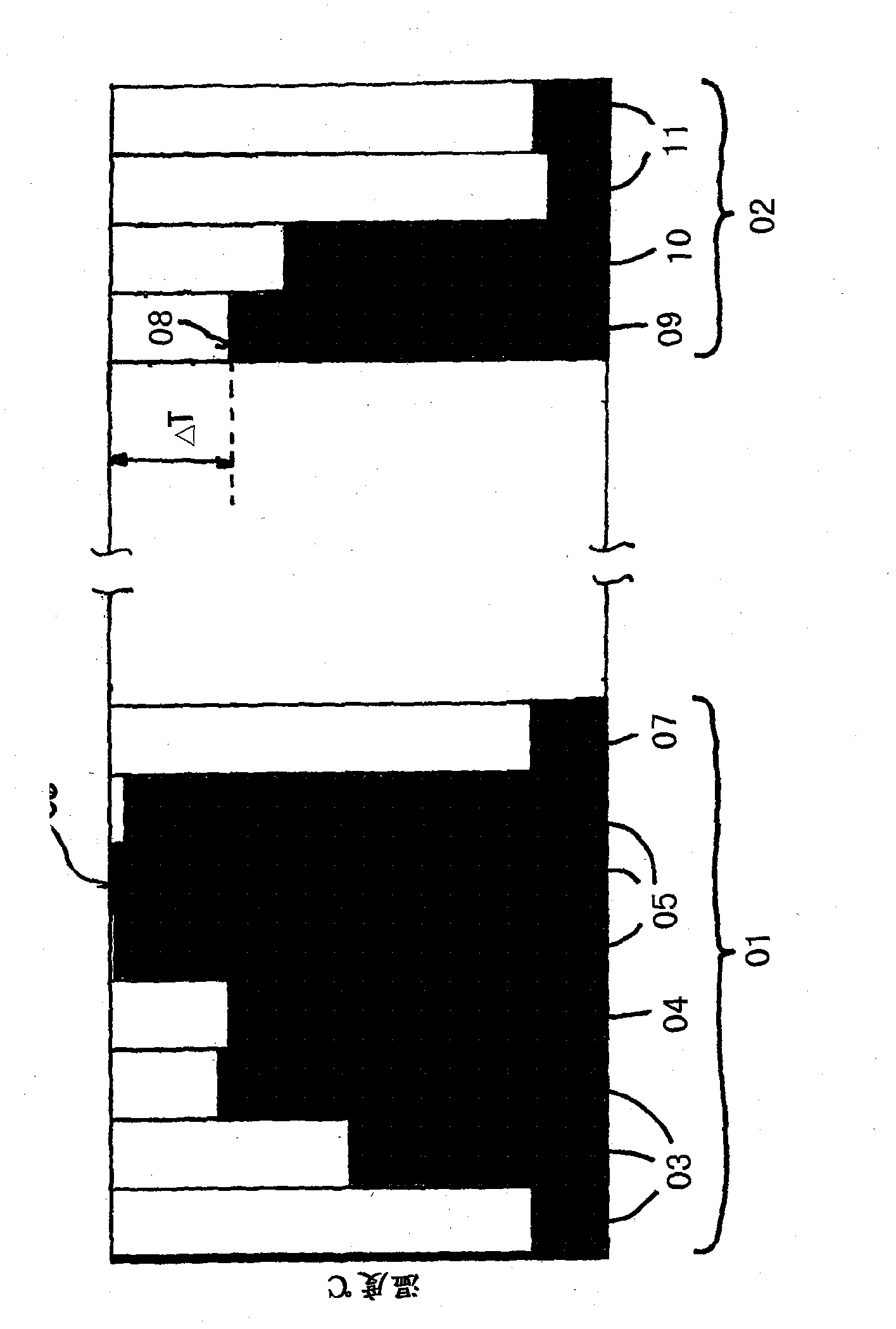

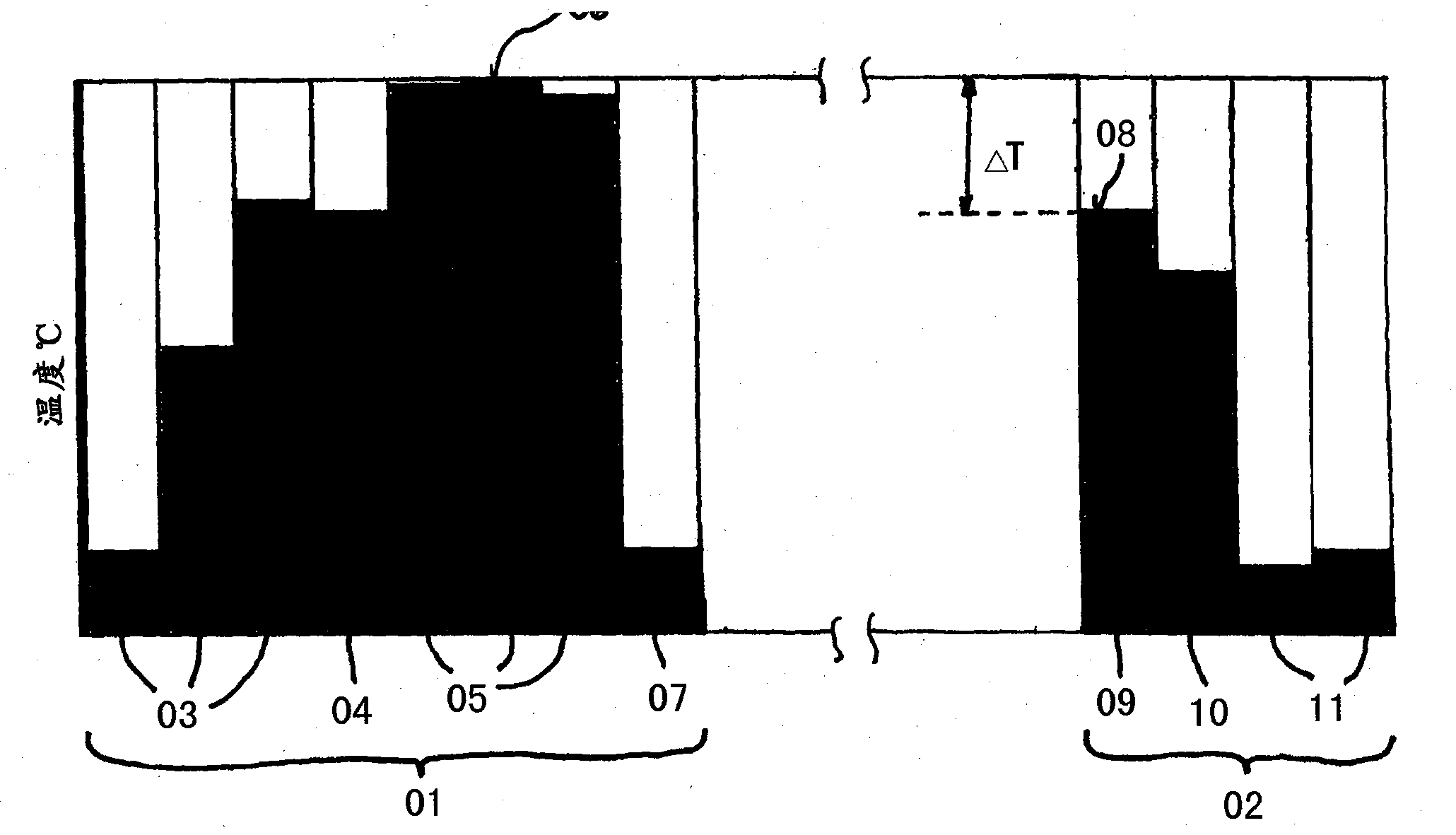

[0022] figure 1The temperature levels of a partial process are shown on the one hand in the brewhouse plant 01 and on the other hand in the filling plant 02 . Here, in the brewhouse plant 01 , the wort is successively heated up to a maximum temperature level 06 during a mashing process 03 , a refining process 04 and a wort boiling process 05 and subsequently cooled down in a wort cooling process 07 . The maximum temperature level 08 for the bottle washing process 09 is determined in the filling plant 02 , whereas the temperatures are significantly lower in the pasteurization process 10 and in the filling process 11 . The difference between the maximum temperature 06 in the brewing plant 01 and the maximum temperature 08 in the filling plant 02 is the basis of the brewing plant according to the invention, which has a function for supplying the brewing plant 01 with process heat and a separate energy supply grid supplying the filling plant 02 with process heat.

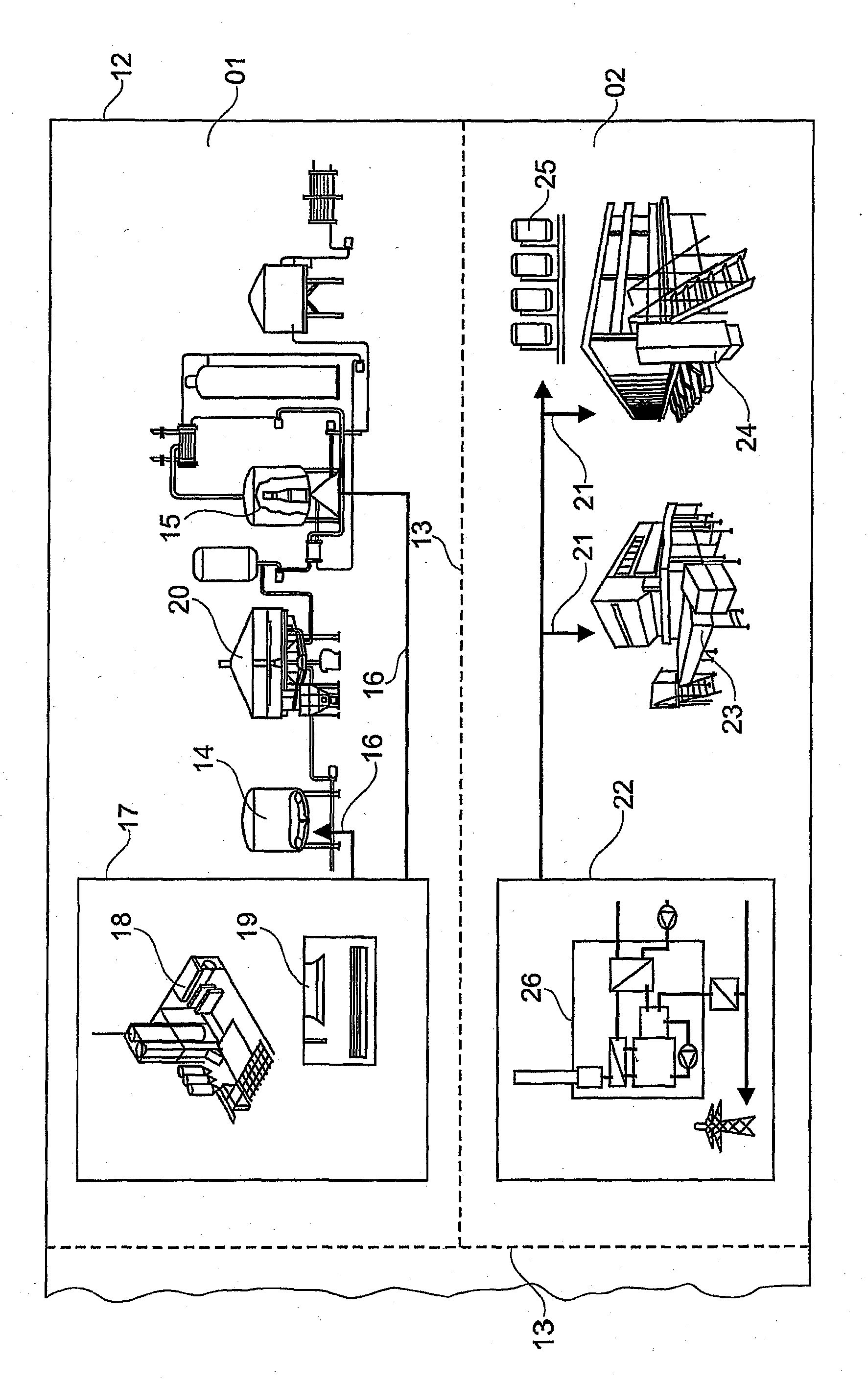

[0023] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com