Laser optical fiber coupling device containing non-imaging optical element

A fiber coupling device and non-imaging optics technology, applied in the coupling direction of optical waveguide, can solve the problems of poor illumination uniformity, alternating light and dark stripes, high cost, and uneven spot, so as to reduce damage to laser tubes and optical fibers The probability of high yield, the effect of improving the yield and the simple adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

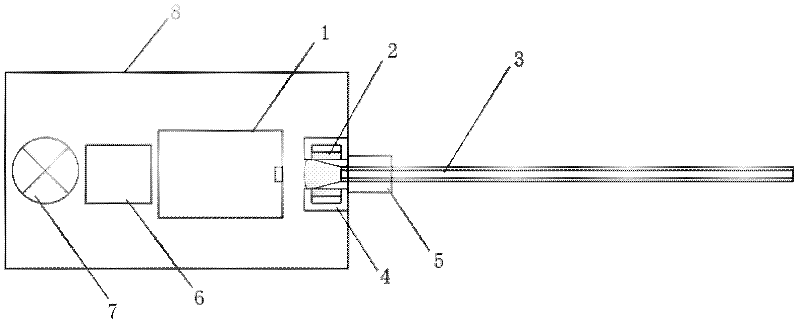

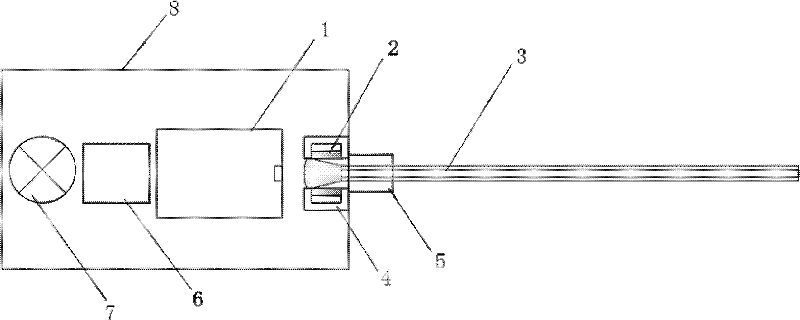

[0010] Depend on figure 1 As shown, a laser fiber coupling device containing non-imaging optical elements, the light source includes: a semiconductor laser tube 1, a non-imaging condenser lens 2 and an optical fiber 3, the semiconductor laser tube 1 emits a beam, and the beam passes through the non-imaging condenser lens 2 , converge on the rear surface of the non-imaging condenser lens 2, and then the beam enters the optical fiber 3 to form a laser fiber light source. The light source also includes: a driving circuit board 6 , a fan 7 and a mechanical packaging shell 8 , and the semiconductor laser tube 1 , the non-imaging condenser lens 2 , the driving circuit board 6 and the fan 7 are integrated and packaged in the mechanical packaging shell 8 .

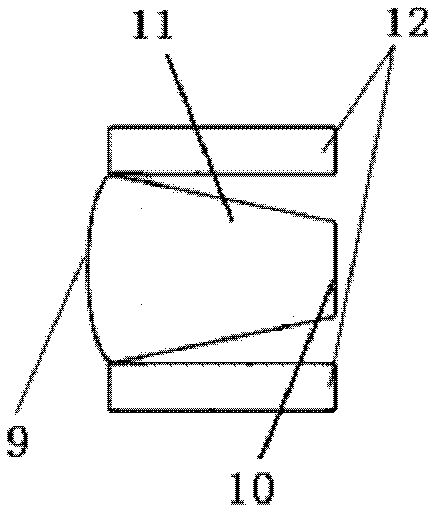

[0011] Depend on figure 2 As shown, the front surface 9 of the non-imaging condenser lens 2 is a spherical surface, the rear surface 10 is a plane, and the side surface 11 is a free-form surface designed according to the princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com