Ship engine control system

A technology for control systems and ships, applied in engine control, machines/engines, motor-driven engines, etc., can solve problems such as engine failure and failure to obtain response performance, and achieve the effect of improving fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

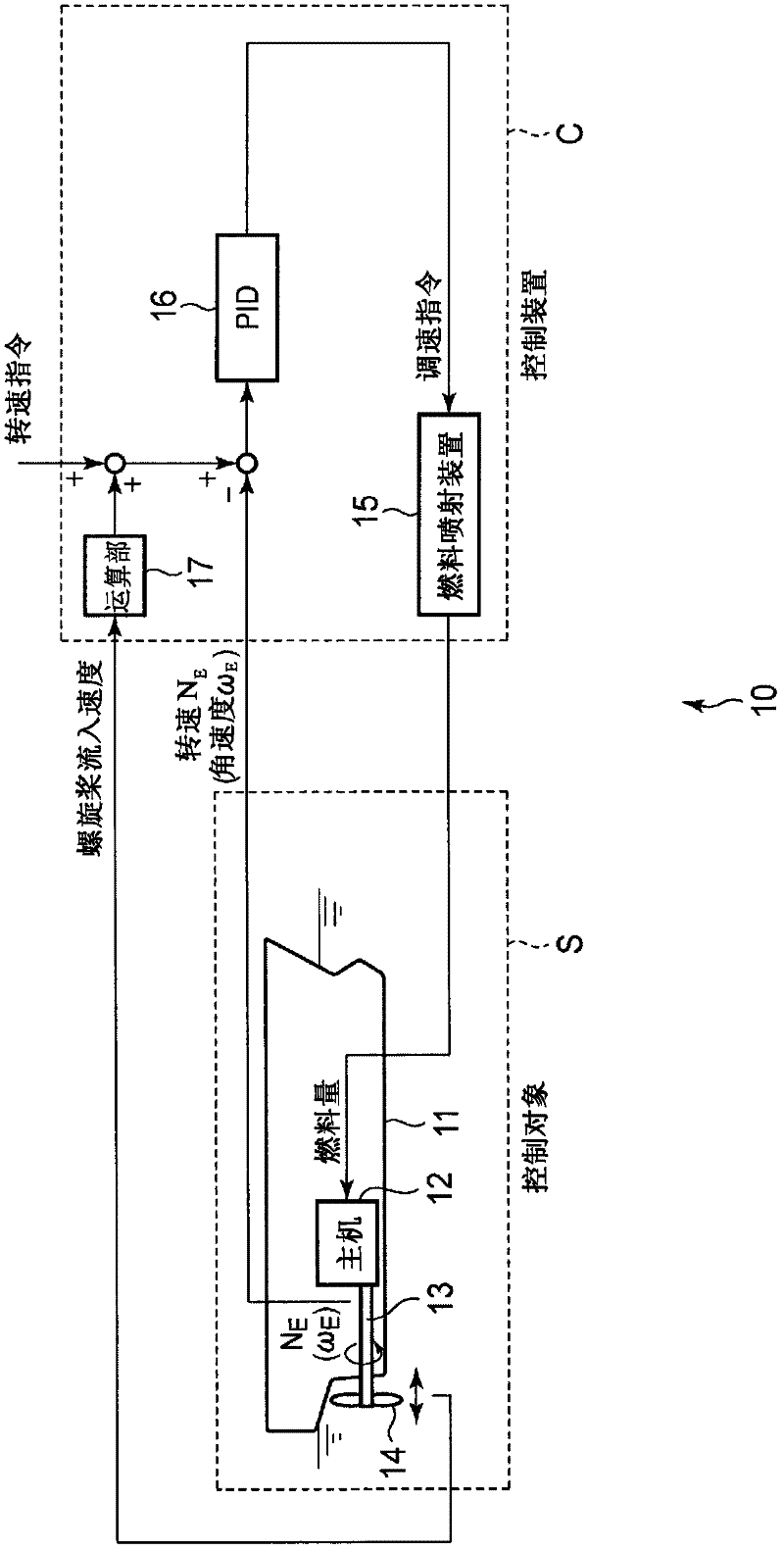

[0036] figure 1 It is a block diagram which shows the whole structure of the marine engine control system concerning 1st Embodiment of this invention.

[0037] The marine engine control system 10 of the present embodiment uses the hull 11 , the main engine 12 , the main shaft 13 , the propeller 14 , etc. as control objects S, and supplies fuel from the fuel injection device (actuator) 15 of the control device C in the main engine 12 . The main shaft 13 connecting the main engine 12 and the propeller 14 is provided with detection of the actual rotation speed N of the main shaft 13 or the main engine 12 E (or angular velocity ω E ) of a known rotational speed (angular velocity) sensor (not shown).

[0038] The control system 10 performs, for example, PID control using the spindle rotation speed (or engine rotation speed) as a rotation speed command (target value), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com