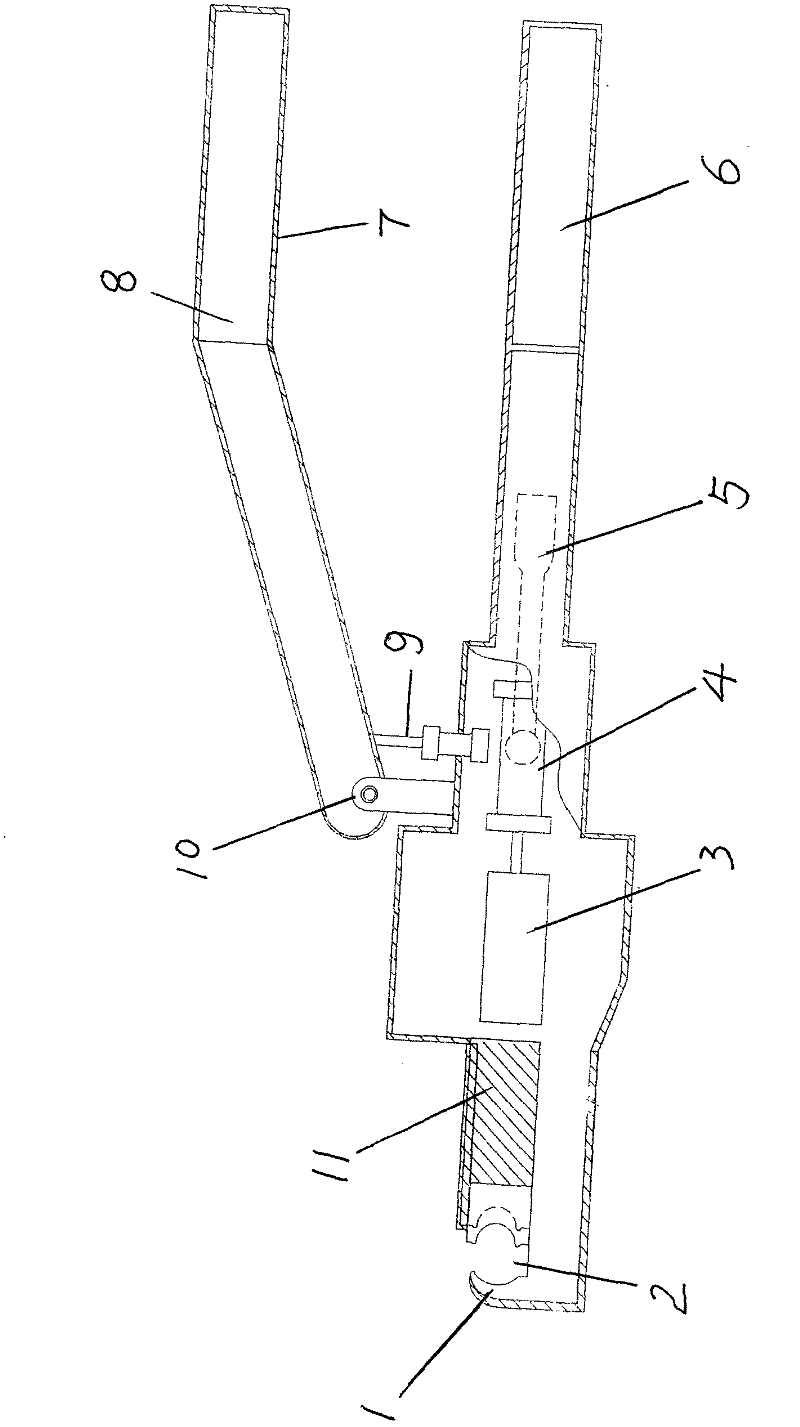

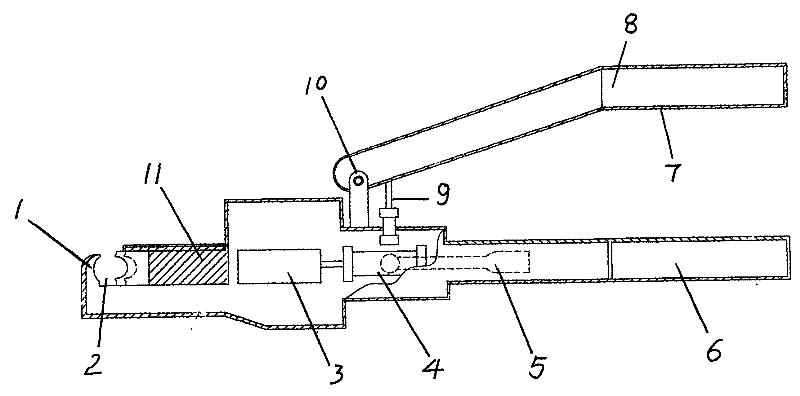

Quadratic miniature-busbar excising forceps

A technology for cutting pliers and busbars, which is applied in the direction of switchgear and electrical components, and can solve the problems of large cutter heads, cutting secondary small busbars, and poor insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Embodiments are described in detail with reference to the accompanying drawings. This cutting pliers is that the blade 1 of the fixed blade is installed in the opening groove at the front end of the fixed handle 6 backwards, and a moving blade 11 is slidably installed in the groove 2 of the fixed handle relative to the fixed blade. A striker 3 is installed in the fixed handle at the rear end of the head to the tail end of the positive moving knife head. The rear end of the striker is connected to the contact of a miniature hydraulic cylinder 4. A decompression button 5 is provided on the hydraulic cylinder, and a power arm 9 is vertically drawn out of the fixed handle on the hydraulic cylinder, the upper end of the power arm is connected to a moving handle 8, and the inner end of the moving handle is connected to a fixed handle. On the fixed support 10 of the handle, one deck insulating sheath 7 is respectively fixed on the outer wall of the fixed handle and the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com