Rotary compressor with air injection function

A technology of rotary compressor and air injection to increase enthalpy, applied in the field of compressors, can solve the problems of affecting the effect of increasing enthalpy, increasing the cost, and the effect of increasing enthalpy is not obvious, so as to improve the effect of increasing enthalpy, improve the energy efficiency of the system, and reduce the production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

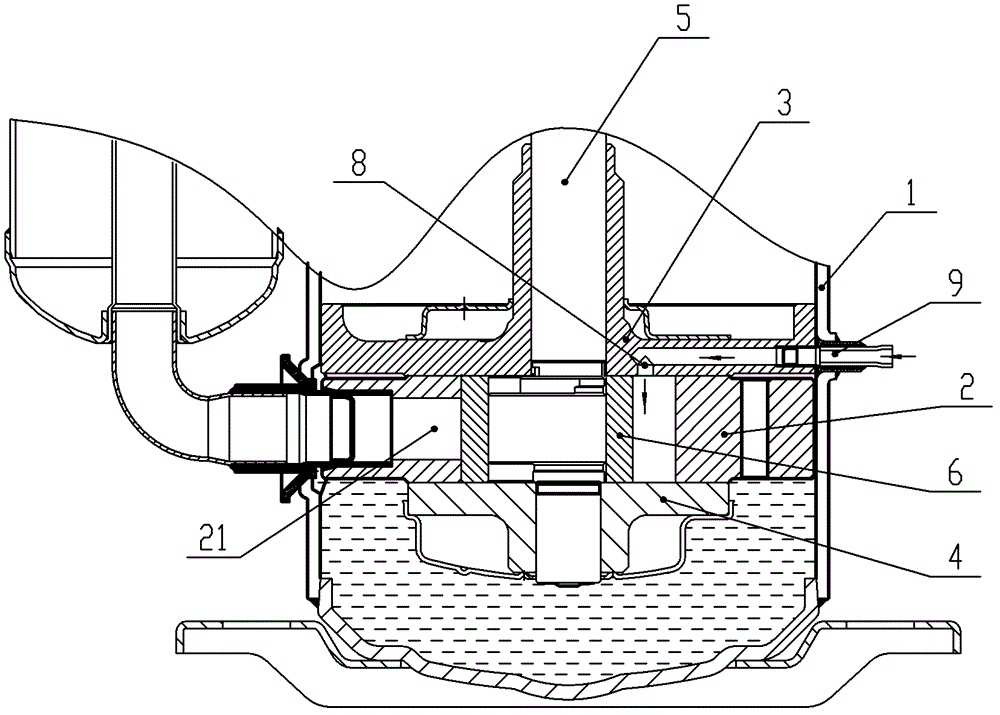

[0025] combine figure 1 and figure 2 As shown, the rotary compressor provided in this embodiment includes: a housing 1, a cylinder 2, an upper flange 3, a lower flange 4, a crankshaft 5, a roller 6, a sliding vane 7, a motor ( figure 1 not shown), etc. A radially telescopic sliding piece 7 is arranged in the cylinder 2, and the two sides of the sliding piece 7 are respectively provided with an air inlet 21 without an air suction valve and an air outlet with an air exhaust valve, and the upper flange 3 and the lower flange 4 are arranged on the The upper and lower ends of the cylinder 2 form a closed cylinder volume with the inner wall of the cylinder 2 . The roller 6 is installed on the eccentric crankshaft 5 , and the roller 6 rolls along the inner wall of the cylinder 2 to form a crescent-shaped working cavity 201 with the cylinder 2 . The sliding plate 7 relies on the force of the spring to make its end closely contact with the outer edge of the roller 6, and divides th...

Embodiment 2

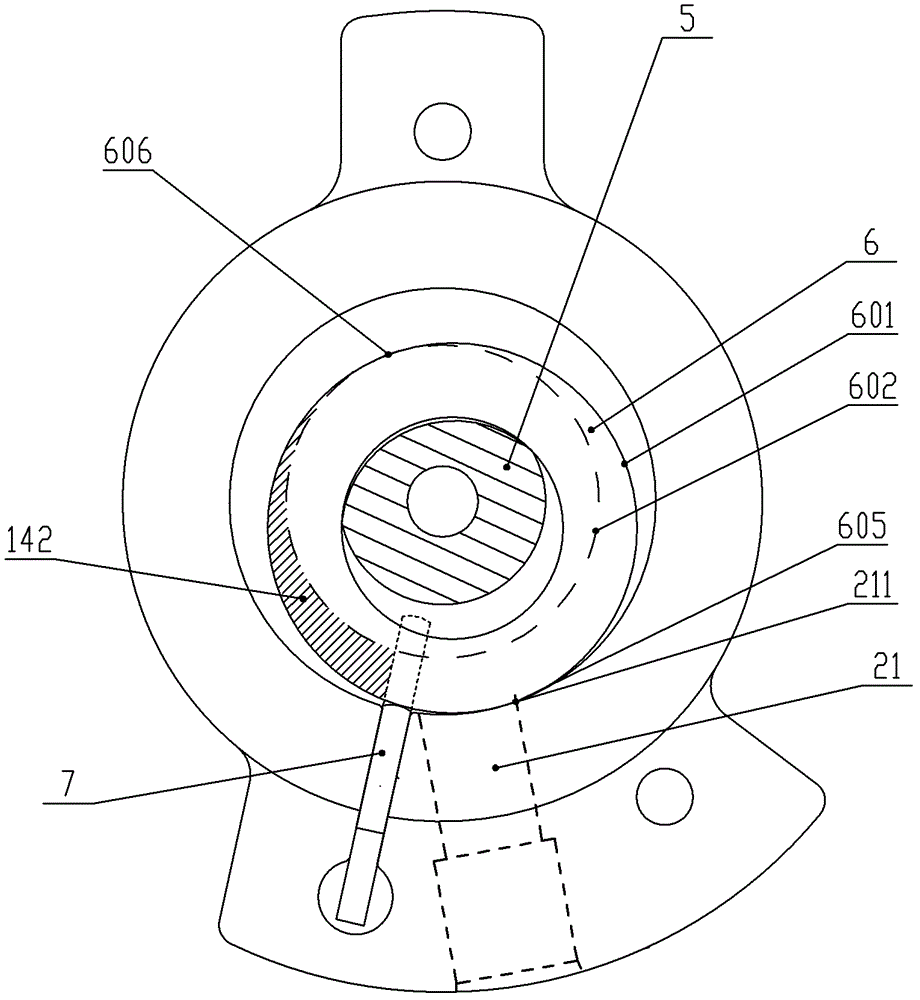

[0029] The difference between the second embodiment and the first embodiment is that the compressor in the first embodiment is a traditional cylinder wall suction hole, which has a suction clearance; the compressor used in the second embodiment adopts a lower flange (or In the case of upper flange and multi-stage cylinder, it may also be the way of the separator) suction hole, and there is no suction clearance volume in this way. For the compressor without clearance, the position of the air injection channel 8 at the end surface of the upper flange 3 has the following two situations:

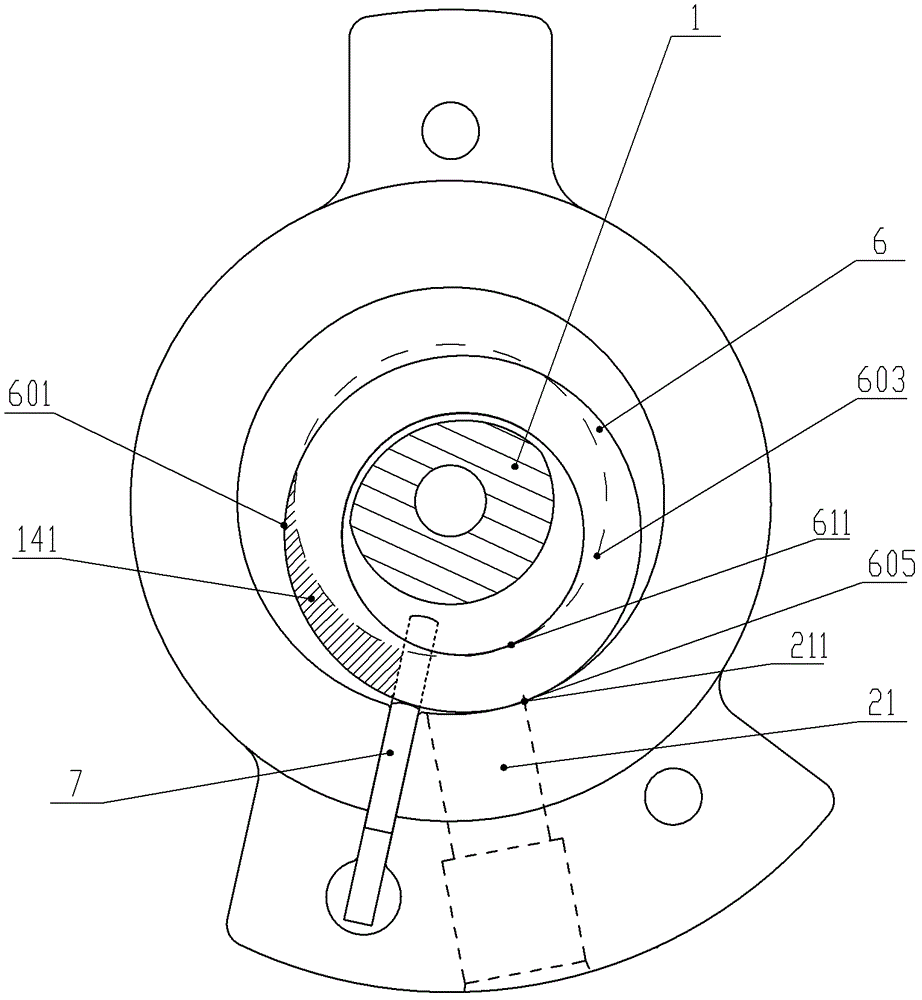

[0030] (1) if Figure 4 shown, for R 1 +e>D 1 -R 2 compressor (where R 1 is the inner radius of the roller, e is the eccentricity, D 1 Roller outer diameter, R 2 inner radius of the cylinder), and the air injection port is set at: when the highest point 605 of the outer circle of the roller 6 (that is, the tangent point between the roller 6 and the inner wall of the cylinder) is located at...

Embodiment 3

[0033] Embodiment 1 and Embodiment 2 limit four different situations, the scope of the air injection channel 8 on the upper flange to open the air injection port, and the present embodiment 3 provides a specific setting scheme for the position of the air injection port and the process of increasing the enthalpy by air injection . Such as Figure 6 As shown, in order to better show the position of the opened air injection port relative to the slide plate 7 and the air intake port 21, the position of the air injection channel 8 is directly drawn with a dotted line on the upper end of the cylinder 2 in an intuitive manner in the figure, and The position where an air injection port 811 of the air injection channel 8 is located. In order to allow the air injection port 811 to open in time and increase the enthalpy increase, the air injection port 811 can be set in a half crescent shape, or a circular air injection port can be used.

[0034] combine Figure 6 to Figure 9 , the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com