Comprehensive mechanized rock roadway tunneling machine

A comprehensive mechanization and tunneling machine technology, applied in the direction of cutting machinery, slitting machinery, and propulsion, can solve the problems of construction workers' lung diseases, affect the health of workers, and low safety factor, and achieve the reduction of silicosis and rheumatism among employees The occurrence of disease, the prevention of various types of roof accidents, and the effect of improving the level of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Carry out the specific embodiment of the present utility model in detail below in conjunction with accompanying drawing:

[0046] 1. The comprehensive mechanized rock roadway boring machine of the present invention

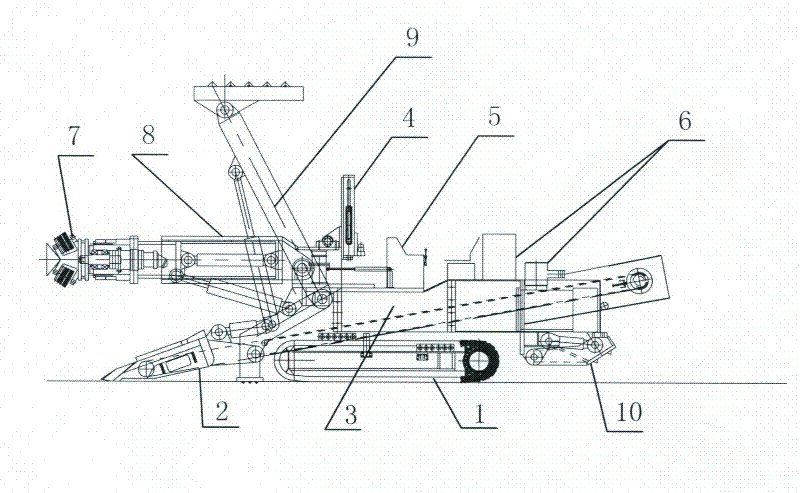

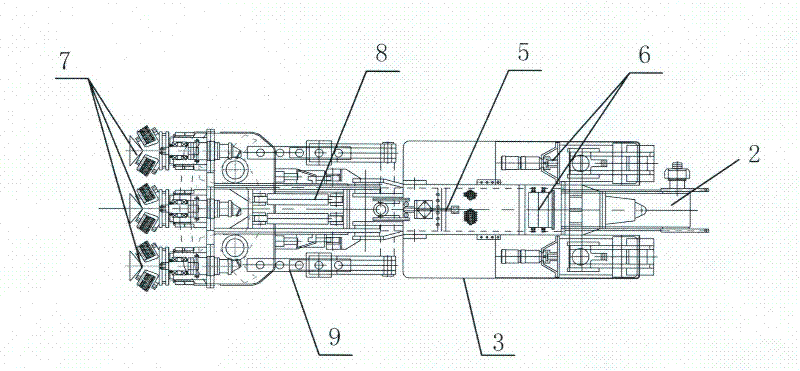

[0047] Such as figure 1 and figure 2 Shown, the comprehensive mechanized rock roadway boring machine that the present invention uses, it is the model (being the model of the embodiment of the present invention) that three cutting devices are adorned with the comprehensive mechanized rock roadway roadheader front portion.

[0048] The comprehensive mechanized rock roadway boring machine includes a crawler walking part 1, a belt conveyor part 2, a fuselage 3 installed on the crawler walking part, a lifting and swinging roof anchor rod and cable drilling machine 4, an operation console 5, and a hydraulic and control system 6; three cutting cutter head devices 7, up and down swing pushing device 8, temporary support and top and bottom plate supporting device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com