Horizontal triangle adhesive tape sticking device

A laminating device and apex technology, applied in tires, metal processing, and other household appliances, can solve problems such as increased production costs, reduced production efficiency, and low pass rate, so as to ensure smoothness and smoothness, and realize lamination operations. The effect of improving productivity and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

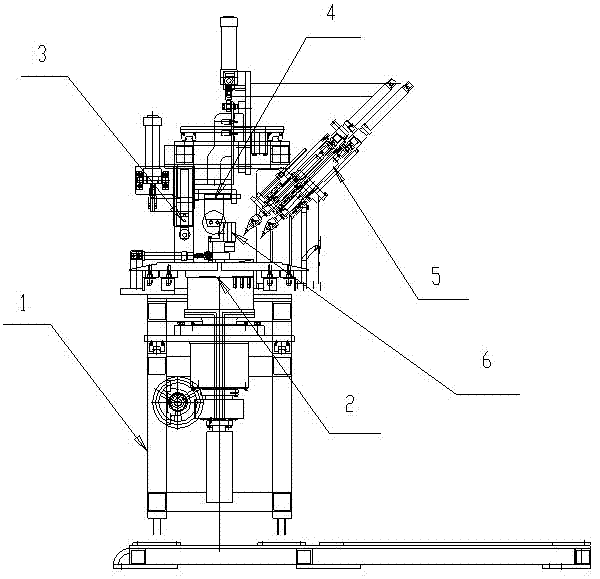

[0063] see figure 1 — Figure 8 , the present invention relates to a horizontal apex bonding device, which includes a frame 1 and a winding device 2 horizontally arranged on the frame 1 and two heating cutter devices 3, and the frame above the winding device 2 1 is also provided with small pinch wheel device 4 and big pinch wheel device 5.

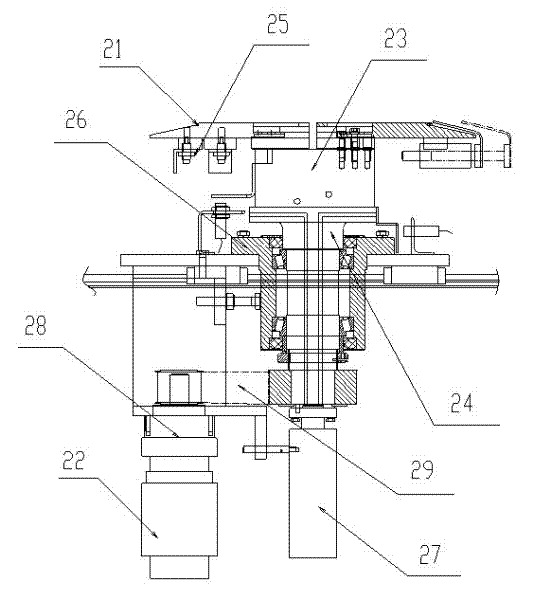

[0064] The winding device 2 includes a winding disk 21 and a servo motor 22, the winding disk 21 is composed of three equally divided sectors, the winding disk 21 is connected to the drive shaft 24 through the air claw 23, and the winding disk 21 A number of small cylinders 25 are installed on the lower end surface, and the several small cylinders 25 are located below the triangular tape, and a mounting seat 26 is sleeved on the periphery of the middle part of the transmission shaft 24, and the mounting seat 26 is installed on the frame 1 through a linear guide rail pair. On the bottom of the transmission shaft 24, a six-way rotary joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com