Separable transformer with magnetic core in nested structure

A nested structure and transformer technology, applied in the direction of transformer/inductor magnetic core, etc., can solve the problems of uneven magnetic flux inside the magnetic core, leakage of high-frequency magnetic field, and easy saturation of the magnetic core, so as to improve efficiency and transmit power capacity , The effect of reducing the leakage of high-frequency magnetic field and increasing the excitation inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

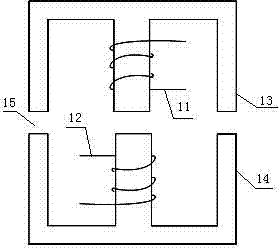

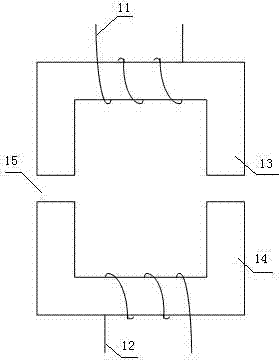

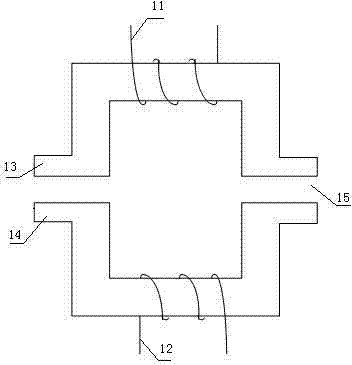

[0018] Refer to the attached Figure 5 , 6 , 7, and 8 describe in detail the implementation of the present invention, and the embodiment takes a UU-shaped magnetic core as an example. Such as Figure 5 As shown, this embodiment consists of a magnetic core 51 wound with a primary coil, a magnetic core 53 wound with a secondary coil, a bobbin 52 , a bobbin 54 , a primary coil 55 , a secondary coil 56 , and an air gap 57 . The structural assembly of the embodiment is that the skeleton 52 is set on the magnetic core 51 winding the primary coil, the primary coil 55 is wound on the skeleton 52, the skeleton 54 is sleeved on the magnetic core 53 winding the secondary coil, and the secondary The coil 56 is wound on the skeleton 54, and the magnetic core 53 wound on the secondary coil is nested in the magnetic core 51 wound on the primary coil, with an air gap 57 in the middle, and the air gap 57 can be formed by an air gap or Constructed of low magnetic permeability materials. Im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com