Vertical-face stone dry-hanging mounting structure

A technology for dry hanging and installation of stone materials, applied in building construction, covering/lining, construction, etc., can solve the problems of low construction efficiency, easy to cause fire, large losses, etc., achieve low labor costs, reduce open fire operations, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

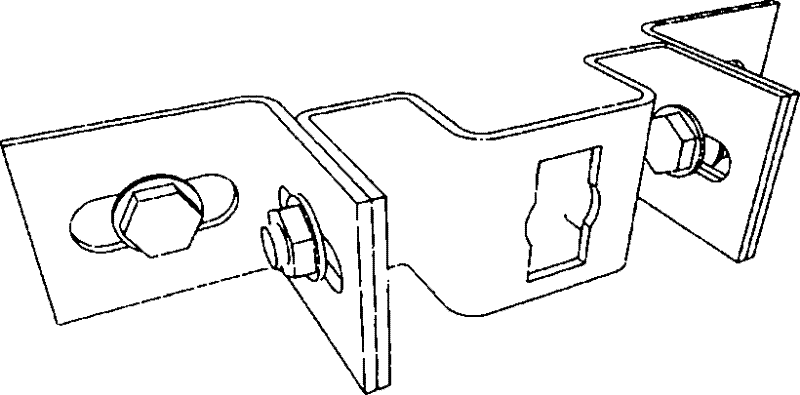

[0034] Such as Figure 9 As shown, a stone facade dry-hanging installation structure includes components such as a keel 2, a wall part 1, a bridge connector 4, a slider 5, and a stone dry-hanging part. The structures of each part can be referred to in the accompanying drawings.

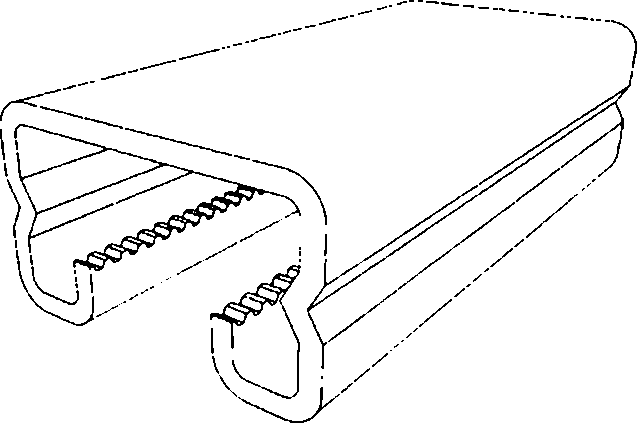

[0035] Keel Structure Reference figure 1 , the keel can be divided into vertical keel 2 and horizontal keel 3 according to the different directions of setting, and the vertical keel 2 and the horizontal keel 3 are connected by bridge connector 4 .

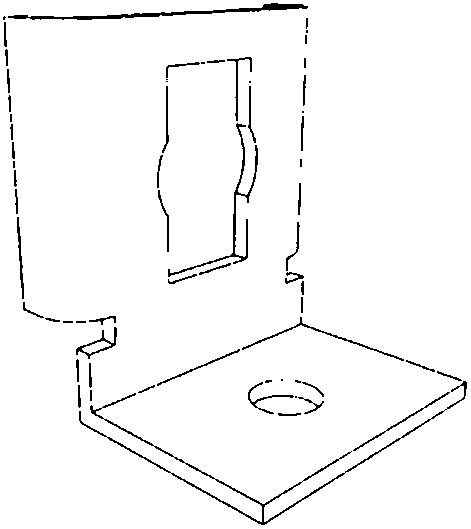

[0036] The transverse keel 3 is fixed to the wall body through the wall connecting piece 1, and the wall connecting piece 1 is fixed to the wall body through expansion bolts or chemical anchor bolts. The slider 5 is installed on the vertical keel 2 through an adjustable fixing piece. The slider 5 can move along the vertical keel 2 when adjustment is required. The structure of the vertical slider refers to image 3 , the stone dry hanger is fixedly connec...

Embodiment 2

[0046] Such as Figure 10 As shown, the difference between this embodiment and the first embodiment is that the vertical keel 2 is located behind the horizontal keel 3 and close to the wall. The vertical keel 2 is fixed to the wall through the wall piece 1 . Such as Figure 4 As shown, the transverse slider can move along the transverse keel 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com