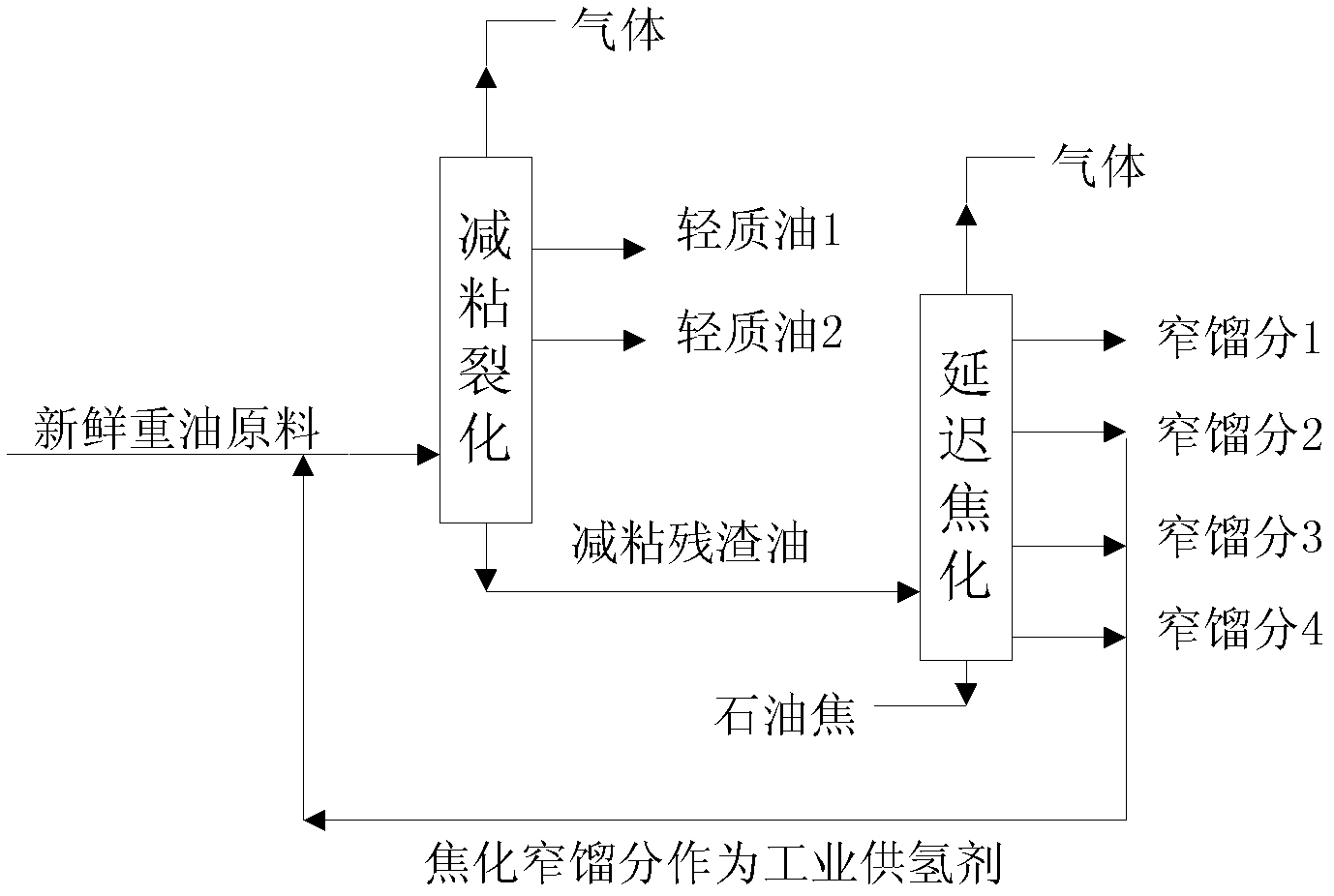

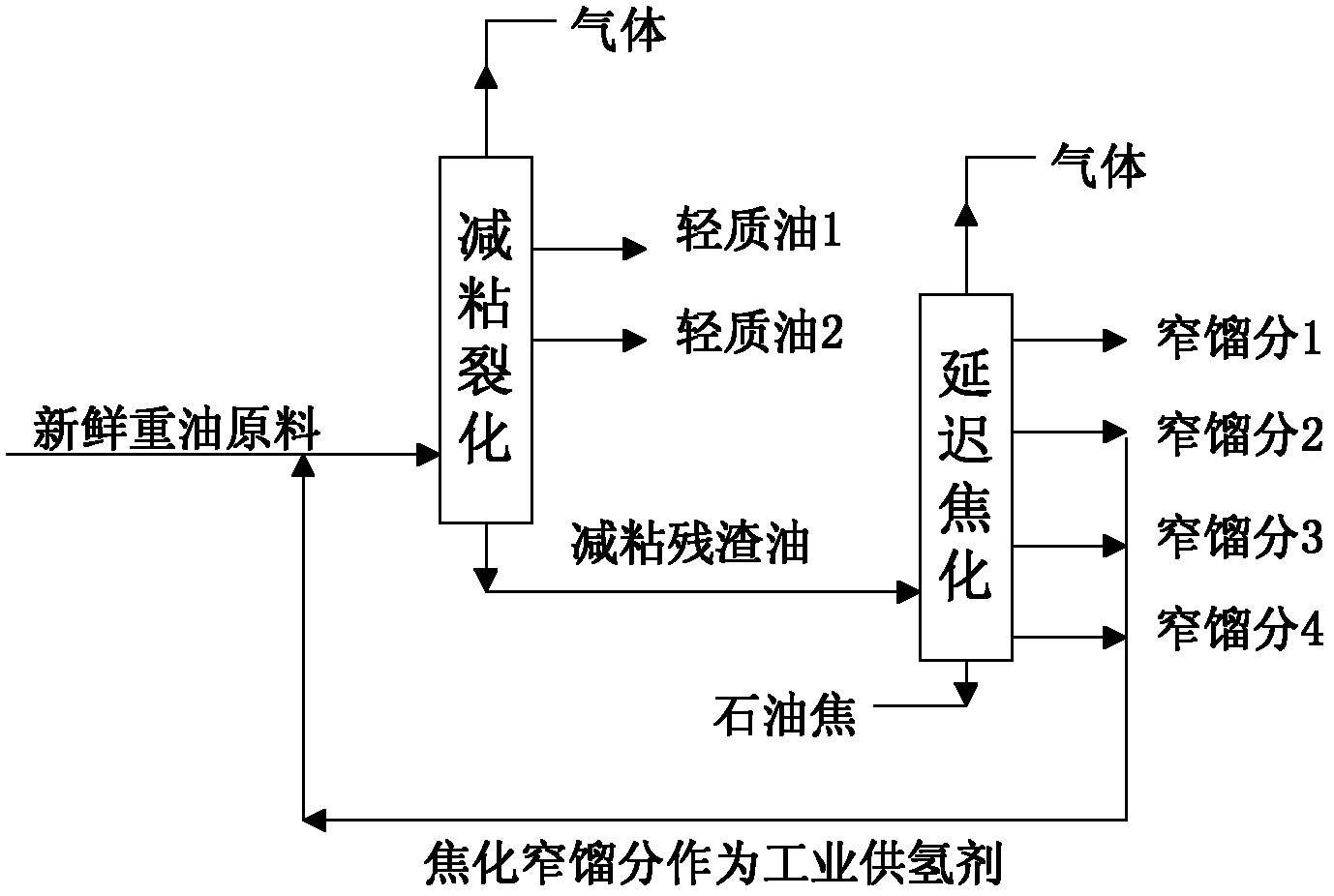

Visbreaking-coking combined process method by hydrogen generated from heavy oil

A combined process and hydrogen supply technology, which is applied in the direction of only multi-stage series refining and cracking process treatment, to achieve the effects of increasing diesel yield, strong competitiveness, and reducing hydrogen supply costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Fresh heavy oil raw material (a kind of super heavy oil, wherein the viscosity at 80°C is 1454mm 2 / s) and coking narrow fraction (350-420°C) are blended at a ratio of 0.05-0.50, and the obtained blended oil is subjected to visbreaking process. The reaction conditions are: reaction temperature 420°C, residence time 30min, reaction pressure 0.4 MPa(G), the viscosity-reduced product is separated by a fractionation tower, and the gas and gasoline fractions are separated, and the obtained viscosity-reduced residual oil is subjected to delayed coking processing. The coking reaction conditions are: reaction temperature 490 ° C, coke tower top pressure 0.18MPa(G). Results The product yields of the combined process were as follows: coke yield 11.94%, gas yield 7.42%, liquid yield 80.64%, light oil 54.10% (including diesel oil 32.26%).

Embodiment 2

[0025] Fresh heavy oil raw material (a kind of super heavy oil, wherein the viscosity at 80°C is 1454mm 2 / s) and coking narrow fraction (240-350°C) are blended at a ratio of 0.05-0.50, and the obtained blended oil is subjected to visbreaking process. The reaction conditions are: reaction temperature 420°C, residence time 30min, reaction pressure 0.4 MPa(G), the viscosity-reduced product is separated by a fractionation tower, and the gas and gasoline fractions are separated, and the obtained viscosity-reduced residual oil is subjected to delayed coking processing. The coking reaction conditions are: reaction temperature 490 ° C, coke tower top pressure 0.18MPa(G). Results The combined process yields were as follows: coke yield 12.44%, gas yield 7.46%, liquid yield 80.10%, light oil 55.65% (including diesel oil 32.49%).

[0026] Comparative Example 1: The fresh raw material of heavy oil is directly processed according to the conditions of delayed coking in Example 1, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com