Bidirectional bias cutting device of triple-side book cutting machine

A technology of oblique cutting and face cutting, which is applied in metal processing and other directions, and can solve problems such as increasing the workload, difficulty in cutting on three sides, and affecting the production efficiency of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

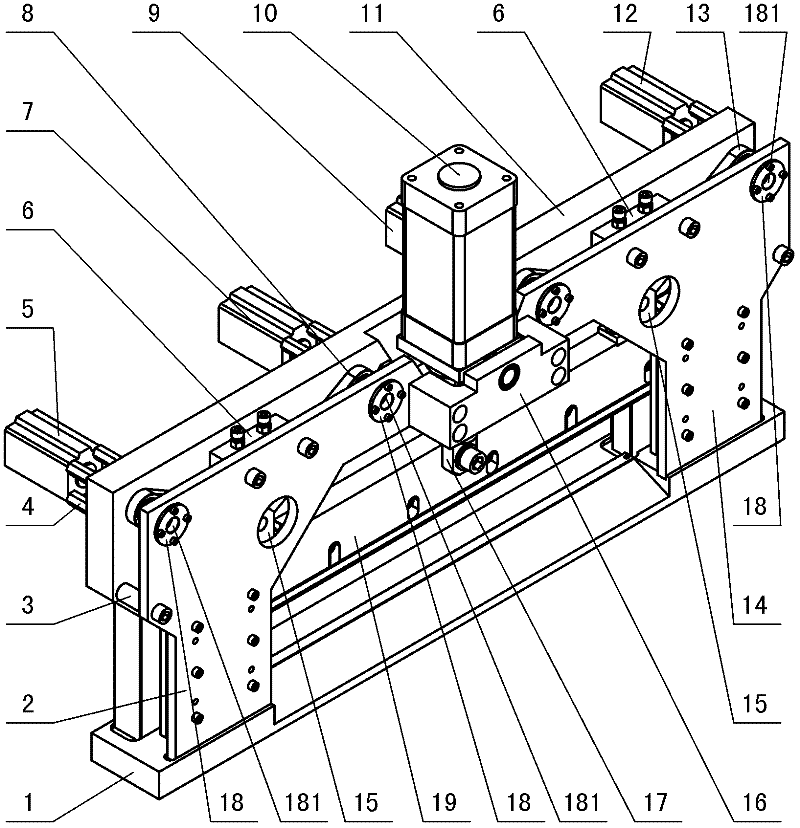

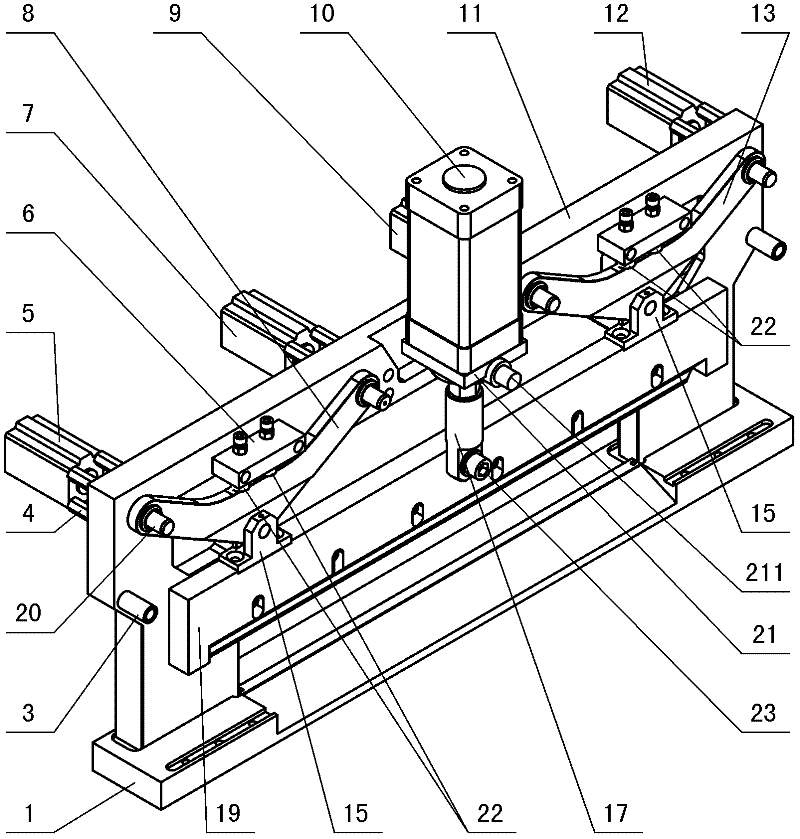

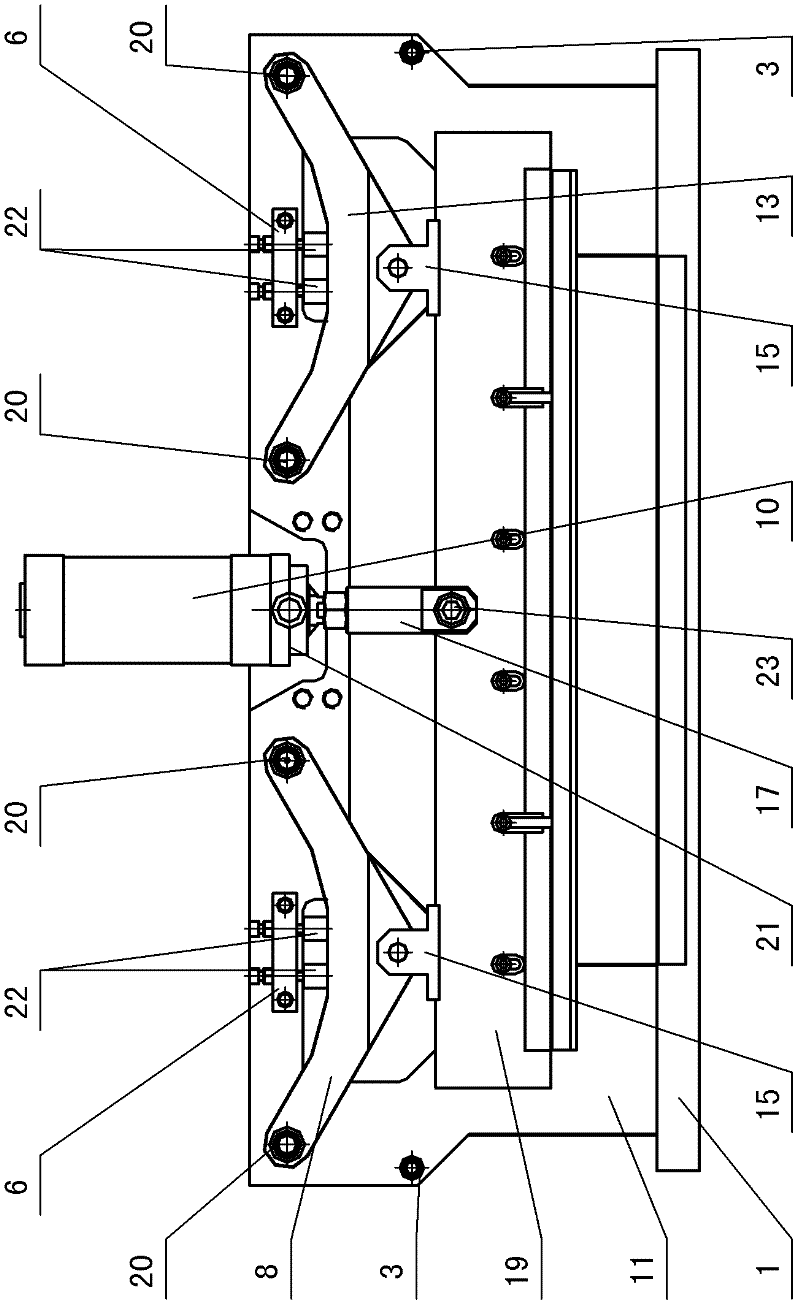

[0022] The two-way beveling device of the three-sided book cutter has a main workbench 1, on which a gantry frame 11, a left front riser 2, and a right front riser 14 are connected, and between the gantry frame and the left and right front risers Riser spacer 3 and contour block 6, the main workbench, gantry frame, left front vertical panel, right front vertical panel, vertical panel spacer and contour block are connected into a whole frame by screws; contour pad Block 6 is connected with cutter upper buffer pad 22 below, and the effect of this buffer pad is to make auxiliary positioning to cutter body when cutter body is returned to the highest position, and the height position of cutter upper buffer pad can pass the screw on its top. Nuts are used to adjust; left and right front vertical plates 2, 14 tops facing each other are connected with a cylinder fixed front seat 16 with screws, and the cylinder fixed front seat and the gantry frame are pivotally straddled by a shaft co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com