Eight-degree-of-freedom series-parallel combined automatic welding robot

An automatic welding, degree of freedom technology, applied in the field of robots, can solve the problems of inability to meet high-precision welding operations, low carrying capacity of welding robots, and large power consumption, achieve large robot dexterity, avoid limited activity space, and high load. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

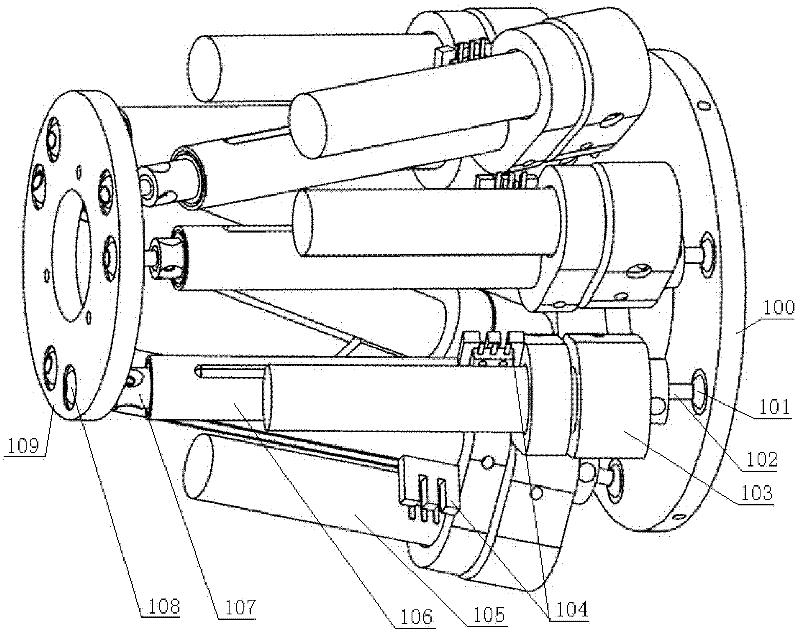

[0016] Such as Figures 1 to 4 As shown, a specific embodiment of the present invention is given. In the figure, an eight-degree-of-freedom hybrid automatic welding robot is composed of two parts: a six-degree-of-freedom parallel robot 1 and a two-degree-of-freedom orientation adjustment mechanism 2, the above The two parts are connected in series through a mechanism static platform 200 .

[0017] Such as figure 2 , Figure 4 As shown, the above-mentioned six-degree-of-freedom parallel robot 1 includes a base 100, a moving platform 109, and mechanical legs 106 between the two. Respectively hinged with the first ball hinge 101 and the second ball hinge 108 on the base 100 and the moving platform 109; the mechanical leg 106 is driven by a ball screw nut mechanism; the mechanical leg 106 adopts a double-layer sleeve structure, wherein the outer sleeve 115 It runs through the entire mechanical leg, and its bottom is installed in the sleeve box 116. A drive motor 105 and a supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com