Process for producing lactic acid bacterium having enhanced immunomodulating activity

An immunomodulation and manufacturing method technology, which is applied in the directions of microorganism-based methods, cosmetic preparations, biochemical equipment and methods, etc., can solve the problems of increased raw materials, undisclosed immunomodulatory effects, and increased processes, and achieves mild efficacy. , The effect of preventing excessive immune function and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

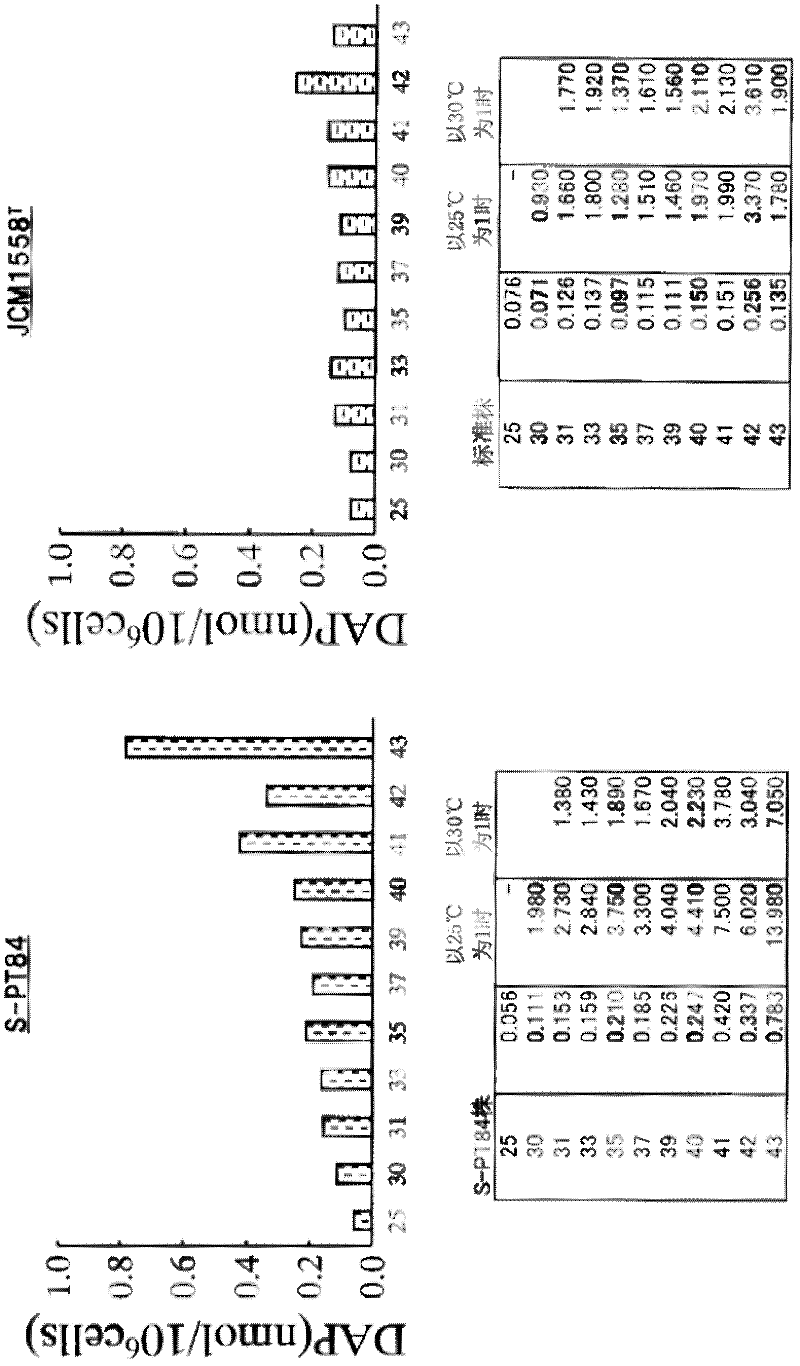

[0079] (The concentration of lactic acid bacteria, the amount of cell wall components, and the induction of interleukin-12 changed according to the culture temperature)

[0080] Lactic acid bacteria culture and cell preparation

[0081] Lactobacillus pentosus S-PT84 (FERM BP-10028) and Lactobacillus pentosus JCM1558 T They were cultured in MRS medium at various temperatures (25°C to 43°C) for 24 hours.

[0082] After the cultivation, centrifuge at 8000rpm for 10 minutes, collect the bacterial cells, wash with physiological saline, and centrifuge again. Then, wash once with normal saline and once with ion-exchanged water, resuspend with appropriate amount of ion-exchanged water to prepare lactic acid bacteria suspension, and measure the final bacterial concentration (unit / mL). Then, it sterilized at 95 degreeC for 1 minute, and freeze-dried. After drying, the total weight was measured to calculate the number of bacteria per unit weight. In addition, Lactobacillus pentosus...

Embodiment 2

[0091] (Concentration of lactic acid bacteria changed by culture temperature, interleukin-12 induction)

[0092] Lactic acid bacteria culture and cell preparation

[0093] Lactobacillus plantarum JCM1149 T At various temperatures (30°C-38°C), Lactobacillus casei JCM1134 T They were cultured in MRS medium at various temperatures (25°C to 44°C) for 24 hours.

[0094] After the cultivation, centrifuge at 8000rpm for 10 minutes, collect the bacterial cells, wash with physiological saline, and centrifuge again. Then, wash once with normal saline and once with ion-exchanged water, resuspend with appropriate amount of ion-exchanged water to prepare lactic acid bacteria suspension, and measure the final bacterial concentration (unit / mL). Then, it sterilized at 95 degreeC for 1 minute, and freeze-dried. After drying, the total weight was measured to calculate the number of bacteria per unit weight.

[0095] In addition, Lactobacillus plantarum JCM1149 T The recommended culture ...

Embodiment 3

[0104] (Cell wall synthetase gene expression analysis and cell wall component amount changed by culture temperature)

[0105] Cell wall synthesis-related enzyme expression analysis primers

[0106] Preparation of primers for Q-RT-PCR of phospho-N-acetylmuramoyl-pentapeptide transferase (mraY), penicillin-binding protein 1A (pbp1A), and penicillin-binding protein 2A (pbp2A) based on the gene information of the genus Lactobacillus whose genome information has been published . 关于引物,作为mraY用引物,使用mraY116:aggaaggtcctaagtggca / mraY895actcgctccaacccttcat,作为pbp 1A用引物,使用pbp1A304:gccgtcgtctcaatcgaaga / pbp1A1724:gtaccagtcttaccagcttg,作为pbp2A用引物,使用pbp2A592:gcgatgtatttgaataacgc / pbp2A1688:agcatcatactggtcatttc。 In addition, all expression analyzes were performed using 16S rRNA gene expression as a control, and primers (S-PT84-16S-f: accgacttcgggtgttacaa / S-PT84 -16S-r: cgcctacatgaagtcggaat).

[0107] expression inducing condition

[0108] Differences in temperature: After culturing lactic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com