Protecting jacket of collecting ring of motor

A protective sleeve and current collection technology, applied in the field of craft tools, can solve the problems of falling off, tight fitting, unable to guarantee the shaft end section, etc., and achieve the effect of ensuring the tightness of the sleeve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

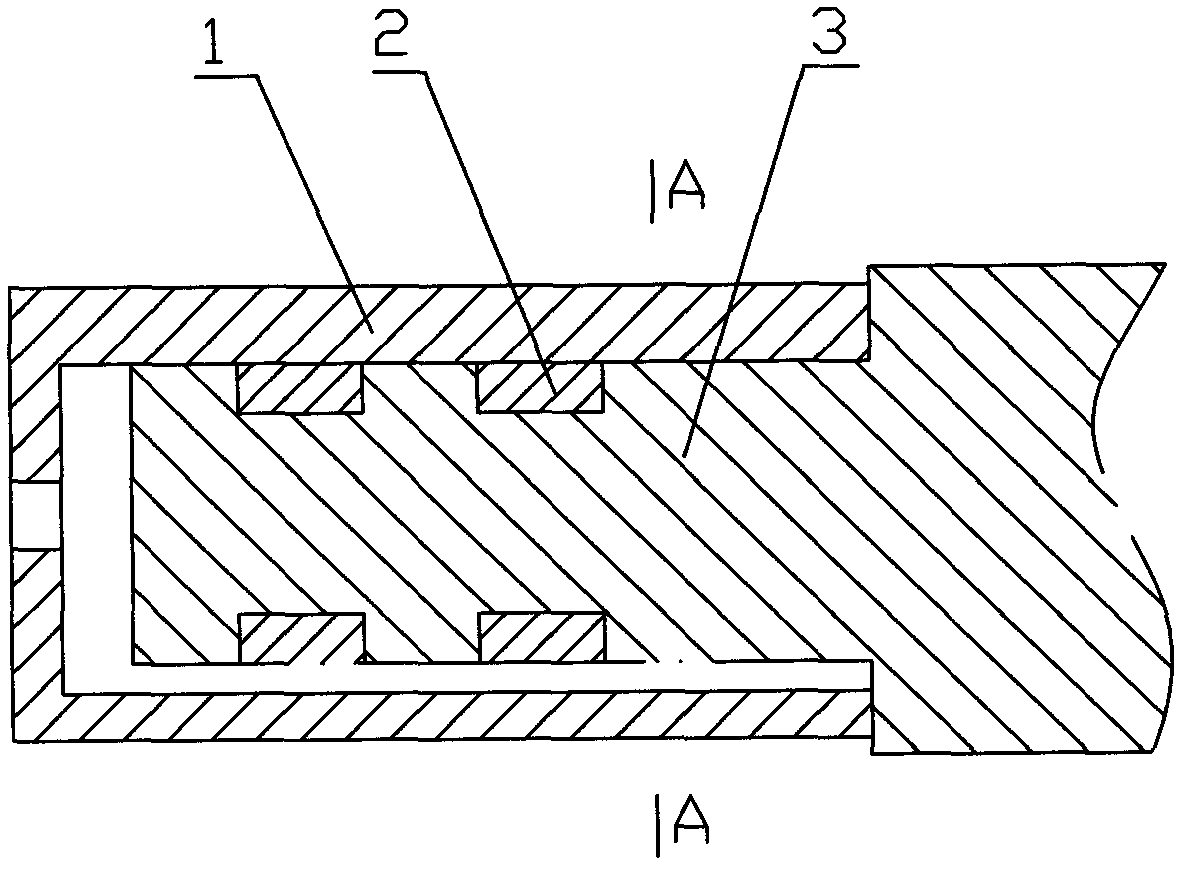

[0009] The structure of the present invention is characterized in that: the protective cover 1 is a cylindrical body, the length of the inner cavity of the protective cover 1 is greater than the length of the shaft end section 3, the inner diameter of the protective cover 1 is greater than the outer diameter of the shaft end section 3, and the inner wall of the protective cover 1 is evenly connected to the inner body. Three radial ribs are extended, and the diameter surrounded by the front edges of the three ribs is smaller than the outer diameter of the shaft end section 3; the bottom cover of the protective sleeve 1 is provided with a through hole in the center.

[0010] The radial height of the radial ribs is 0.3-0.5mm.

[0011] The plastic protective sleeve 1 is formed by injection molding on an injection molding machine. When the three ribs are inserted, elastic deformation occurs and can be compressed backwards or obliquely, so that it can be fixed in close contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com