Method and device for testing control cabinet of electric locomotive

A technology for electric locomotives and testing devices, applied in electrical testing/monitoring and other directions, can solve problems such as high cost, data loss, unfavorable maintenance, etc., and achieve the effect of improving real-time response rate, facilitating maintenance and upgrading, and meeting real-time requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present application provides a test method and device for a control cabinet of an electric locomotive, which can not only meet the requirement of storing various motor models, but also facilitate the maintenance and function expansion of the test device.

[0080] In order to make the purpose, features, and advantages of the present application more obvious and understandable, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

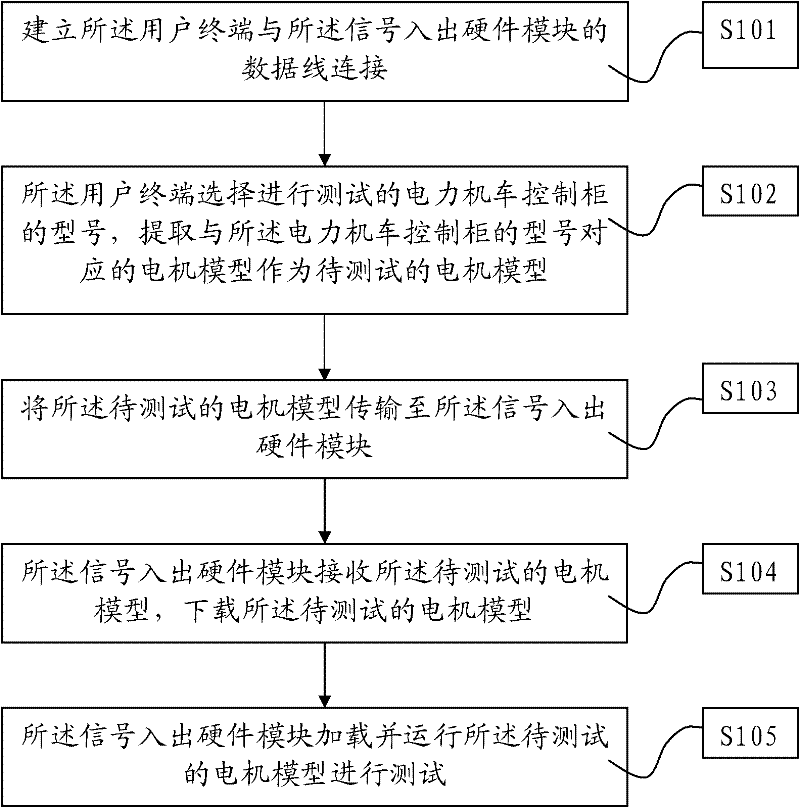

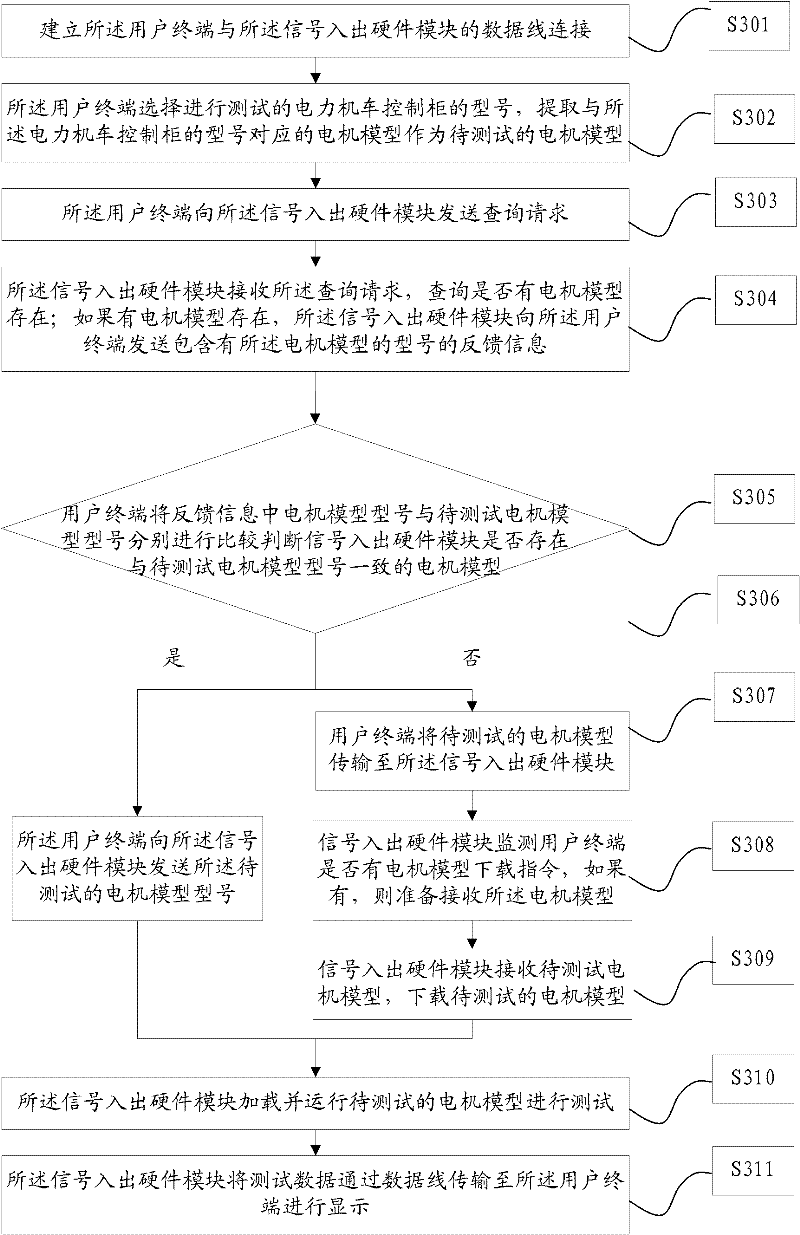

[0081] see figure 1 , is the flow chart of the first embodiment of the test method for the electric locomotive control cabinet of the present application.

[0082] The present application provides a test method for an electric locomotive control cabinet. The method uses an electric locomotive control cabinet test device to test the electric locomotive control cabinet. The electric locomotive control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com