Production line system adaptive to dynamic configuration of equipment and process sequence method thereof

A technology of dynamic configuration and sorting methods, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of not considering the cost, not fully considering the optimal configuration, not being able to adapt to the production line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

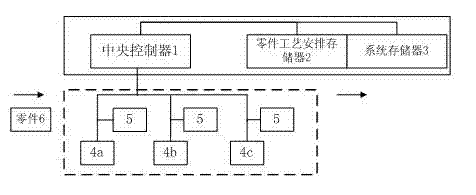

[0042] Such as figure 1 As shown, the present invention is an embodiment of a production line system adapting to the dynamic configuration of equipment. The production line system includes a control system, and the control system includes a central processing unit 1, a parts process arrangement storage 2 and a system storage 3 respectively connected to the central processing unit 1.

[0043] Among them, the central processing unit 1 adopts Intel IPC-601 / P4 2.0G, the part process arrangement memory adopts Kingston 1G SD card, the system memory adopts 80GHDD, and the display device 5 is a 15-inch liquid crystal display.

[0044] The production line system also includes a production line connected to the circuit of the central processing unit 1, and the production line includes three processing devices 4a, 4b and 4c. Display devices 5 are provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com