Apparatus and method for determining high temperature wettability

A technology of wettability and high temperature, which is applied in the direction of measuring devices, furnaces, instruments, etc., can solve the problem that it is difficult to measure the initial contact angle of the system and the kinetics of droplet spreading at isothermal conditions, and the metal samples are easy to oxidize and cannot truly reflect the melting of metals. Eliminate stress, improve test accuracy, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

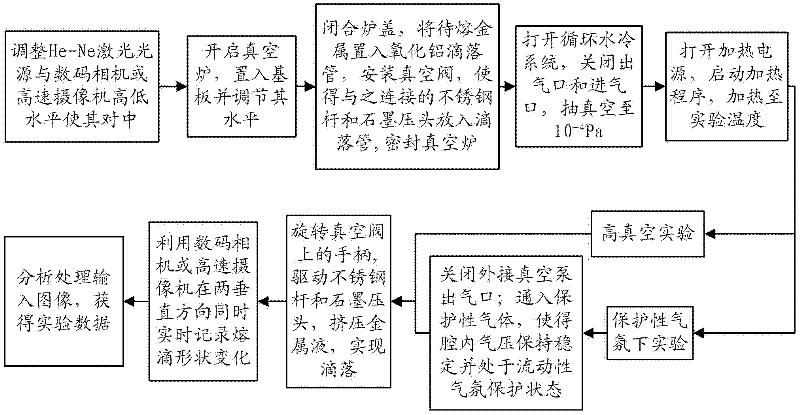

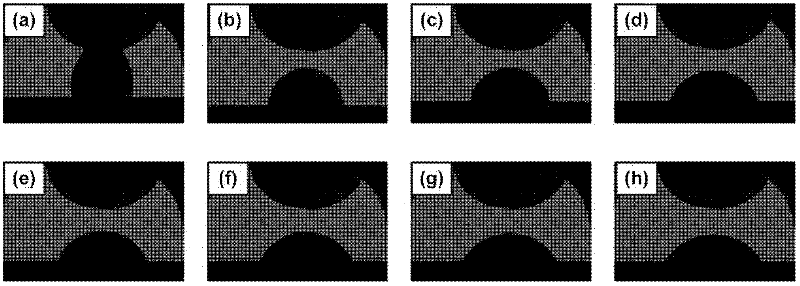

[0062] Embodiment: at 1000 ℃ and purity is 99.999% and the wettability of measuring pure Al on SiC substrate under the Ar gas protection of purification treatment (referring to Figure 1 to Figure 4 ).

[0063] 1. Adjust the position of He-Ne laser light source 21 and CCD digital camera or CMOS high-speed camera 23, so that CCD digital camera or CMOS high-speed camera 23 lens, quartz glass observation window 13, middle shield layer middle position wall through hole, heating body 16 The through hole of the heating body and the axis of symmetry of the He-Ne laser light source 21 are on the same horizontal line. Adjust the focal length of CCD digital camera or CMOS high-speed video camera 23 lenses.

[0064] 2. Open the fastening bolts connecting the lower end of the drip tube support flange 7 and the welding flange on the upper end of the upper cover 3, remove the drip tube support flange 7, and take out the drip tube 9 made of high-purity alumina.

[0065] Open the furnace co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com