Heat pump hot-water supply floor heating device

A heating system and hot water technology, applied in heating systems, hot water central heating systems, heating methods, etc., can solve problems such as detachment or imbalance of the compression mechanism, reduced reliability, low operating efficiency, etc., to reduce refrigerant Effects of reducing load, improving reliability, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

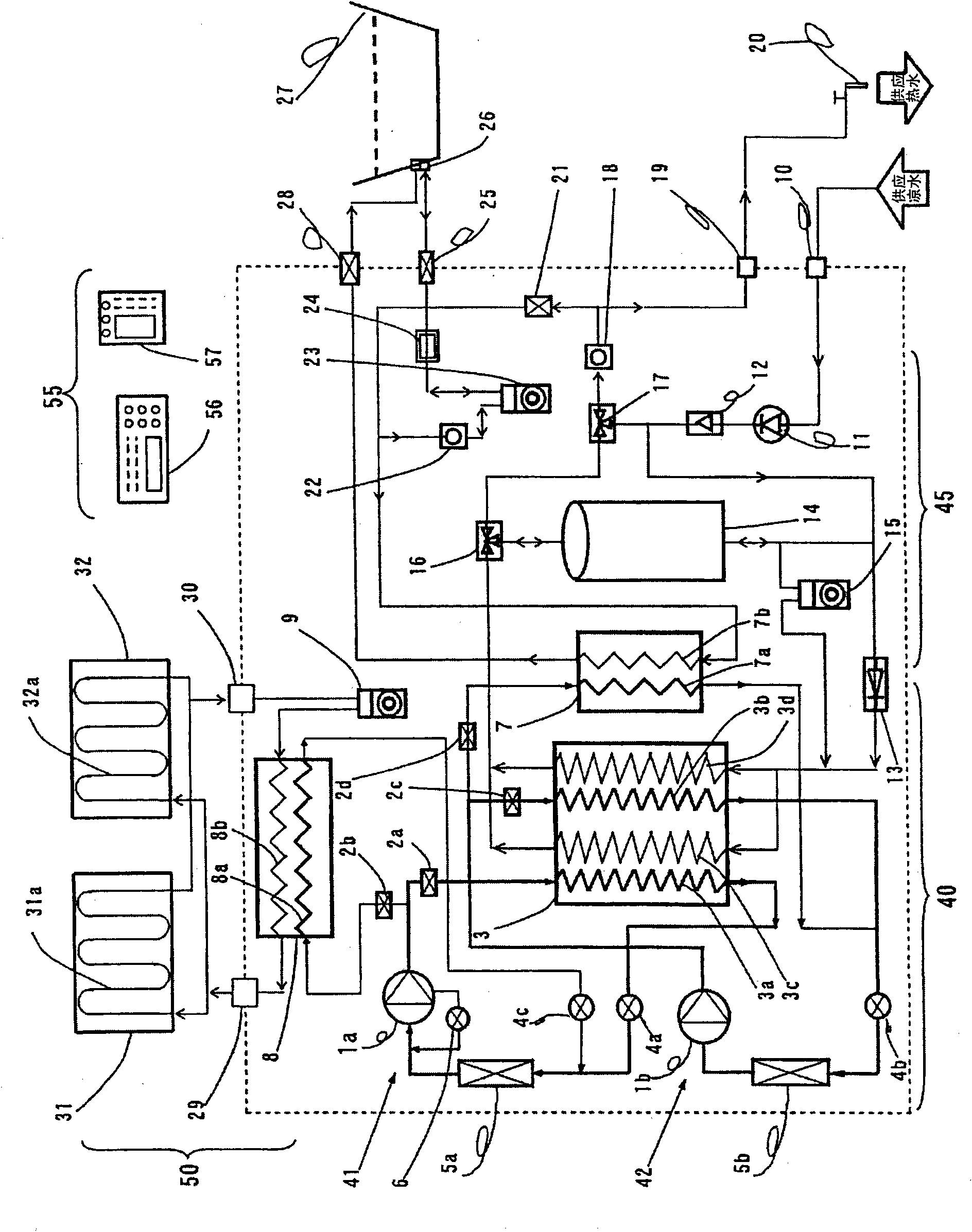

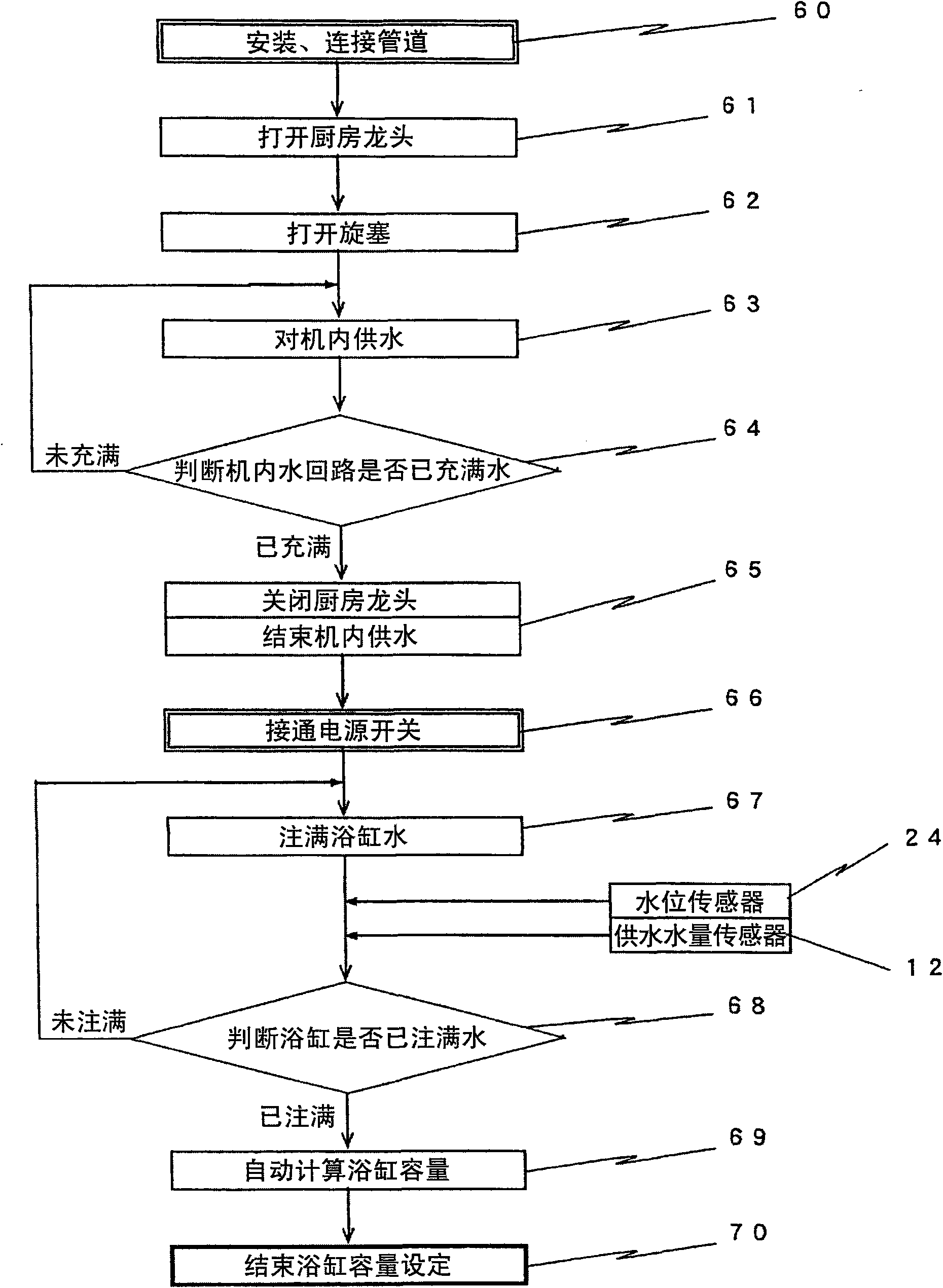

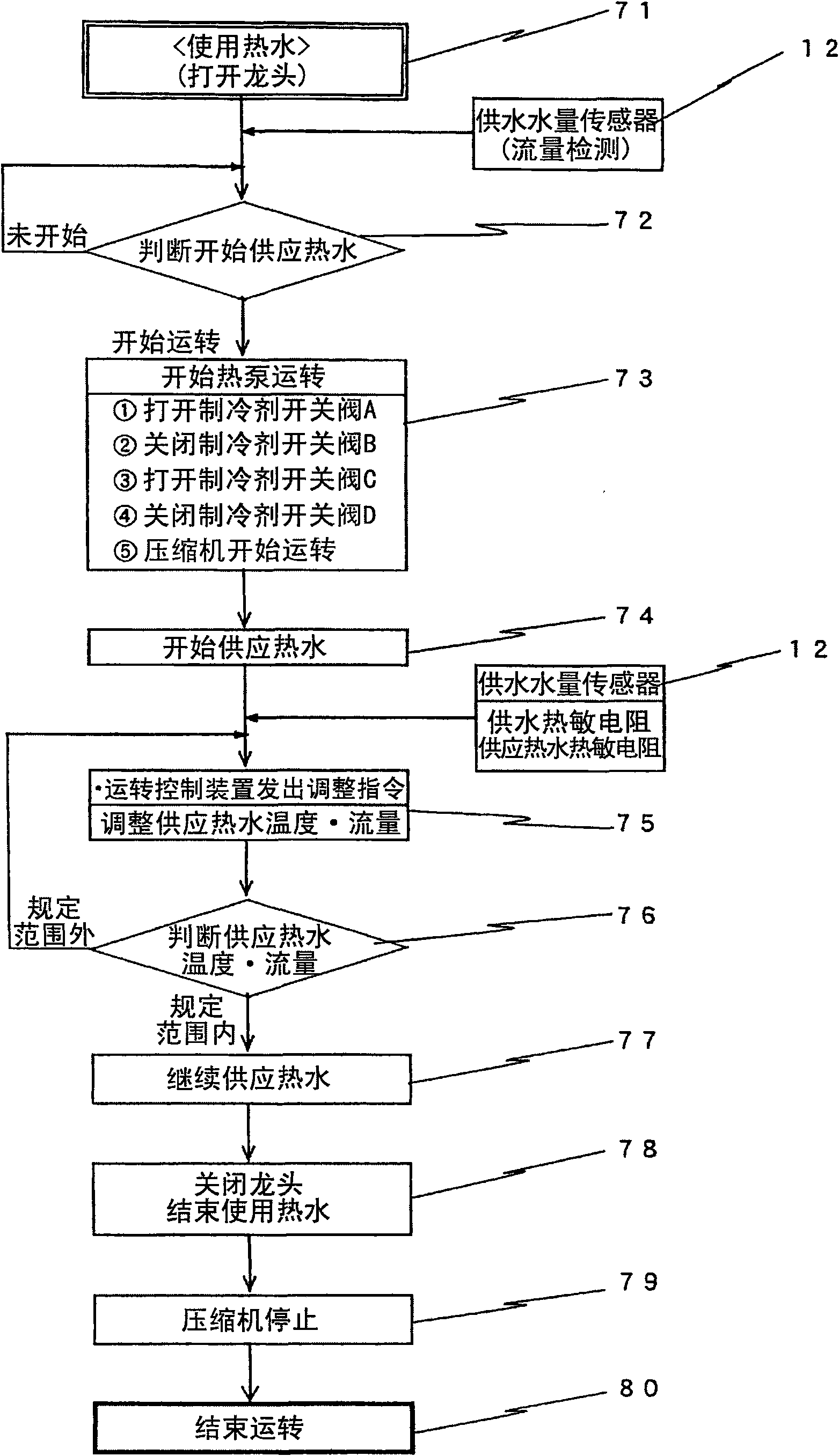

[0035] Below, according to Figure 1-Figure 6 A first embodiment of the present invention will be described.

[0036] figure 1 Among them, the structure of the heat pump hot water supply type floor heating system has: a heat source circuit 40 composed of two heat pump refrigerant circuits of the floor heating side refrigerant circuit 41 and the bath water side refrigerant circuit 42, and a hot water supply circuit 45 , the floor heating heat exchanger 8 and the operation control device 55 as constituent members of the floor heating circuit 50 .

[0037] The heat source circuit 40, the hot water supply circuit 45, and the floor heating heat exchanger 8 are integrally accommodated in the same box, and the operation control device 55 is composed of a separate kitchen remote control 56 and bath water remote control 57.

[0038] In addition, the floor heating devices 31 and 32 as the constituent parts of the above-mentioned floor heating circuit 50 are installed separately from t...

Embodiment 2

[0094] Below, according to Figure 7 A second embodiment of the present invention will be described.

[0095] Figure 7 in, with figure 1 There are three different components: a heating water pipe 37a on the heating side of the bath water heat exchanger 37, a heating water switch valve 35 for switching the heating water flowing to the heating water pipe 37a, and a heat exchange valve 35 for detecting and supplying hot water. The flow sensor 36 for heat exchange of the flow rate of the device 3 .

[0096] Figure 7 in, with in figure 1 The point of difference of the first embodiment described in the above is that the refrigerant pipe 7a for bath water used as the heating side of the heat exchanger 7 for bath water is replaced with the water heating pipe 37a; the water pipe 37a for heating is used to make the slave The hot water supplied by the water supply side heat transfer pipes 3 c and 3 d heated by the heat exchanger 3 flows through the hot water flowing in through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com