Light emitting diode (LED) backlight module and liquid crystal display (LCD) device

A technology for a liquid crystal display device and a backlight module, which can be applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve problems such as wasted man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

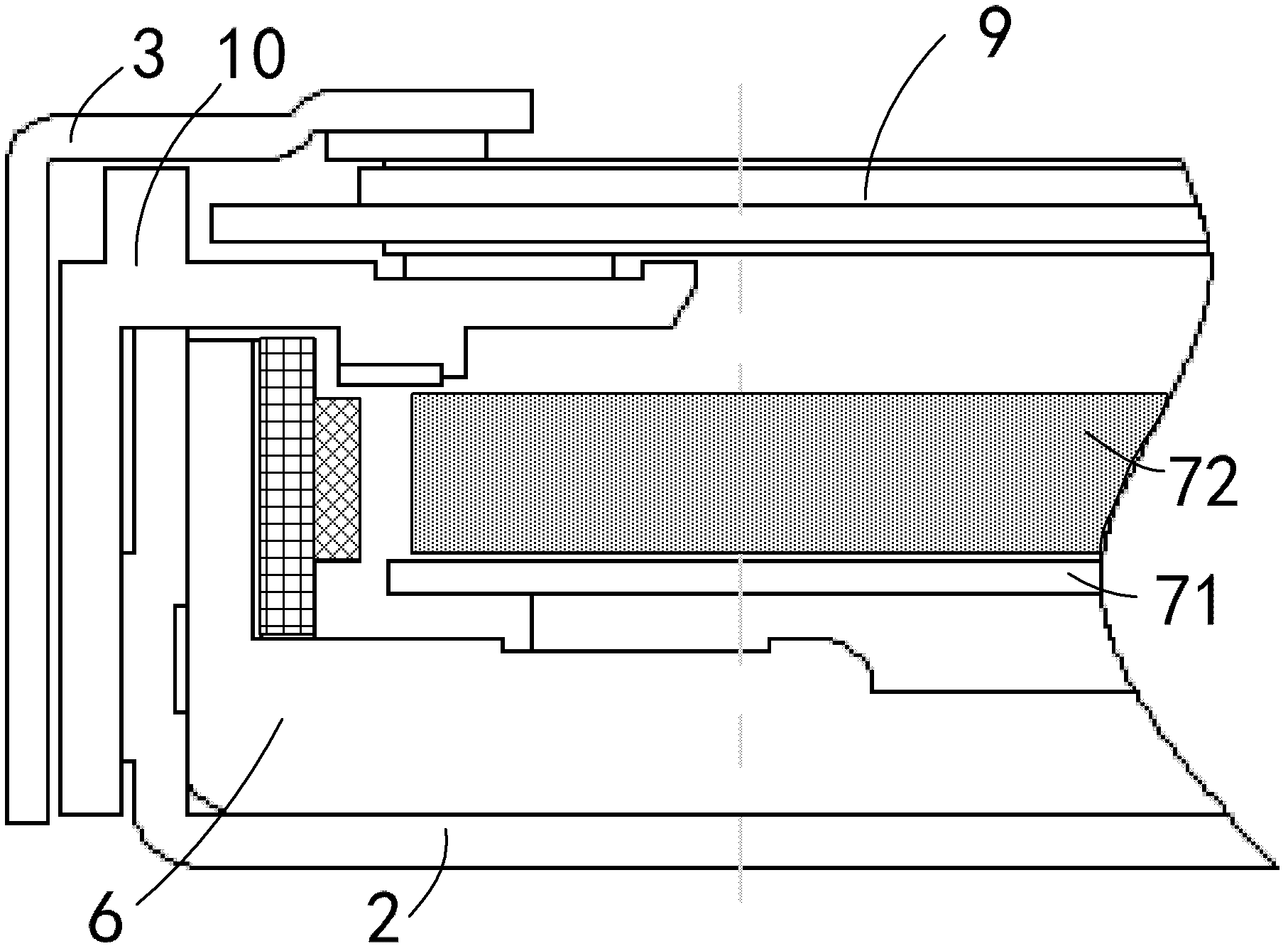

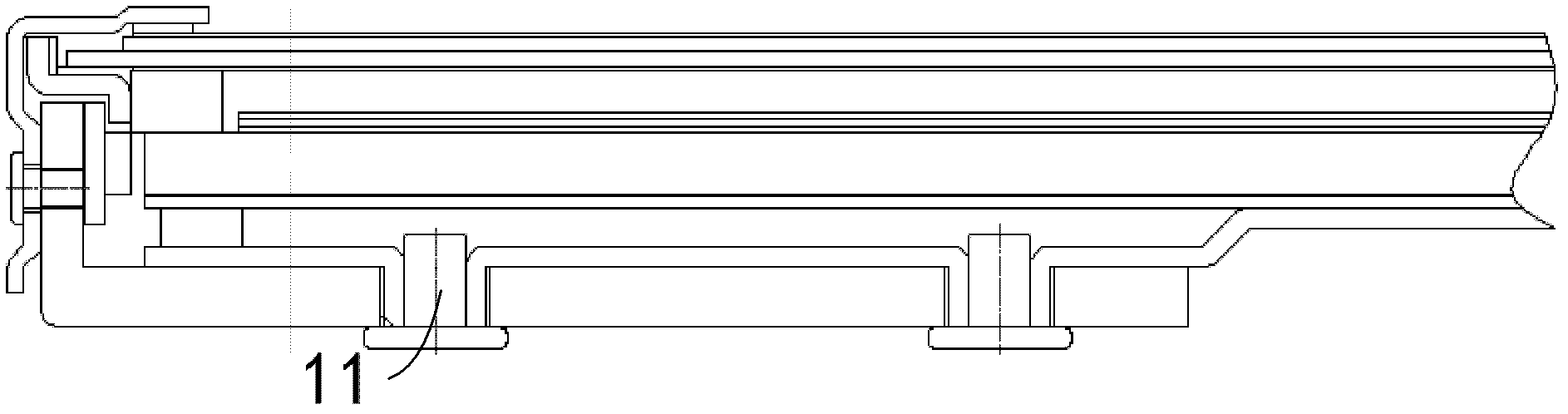

[0024] The backlight module and the liquid crystal display are fixed through the front frame 3 , preferably, the front frame 3 is fixedly connected to the light source fixing device 6 . The existing liquid crystal display device, viewed from the side from the outside to the inside, includes a front frame 3, a plastic frame 10, a back plate 2, and a light source fixing device 6, with a total of four layers of structure; while the front frame 3 and the light source in this embodiment The fixing device 6 is directly fixed and connected, and the plastic frame 10 is directly omitted, and the back plate 2 can be fixedly connected with the light source fixing device 6 behind the LED backlight module without extending to the side of the LED backlight module for fixing, so this implementation On the one hand, the method can reduce the cost; on the other hand, it can also reduce the width of the frame of the liquid crystal display device, which is in line with the trend of thinning and t...

Embodiment 2

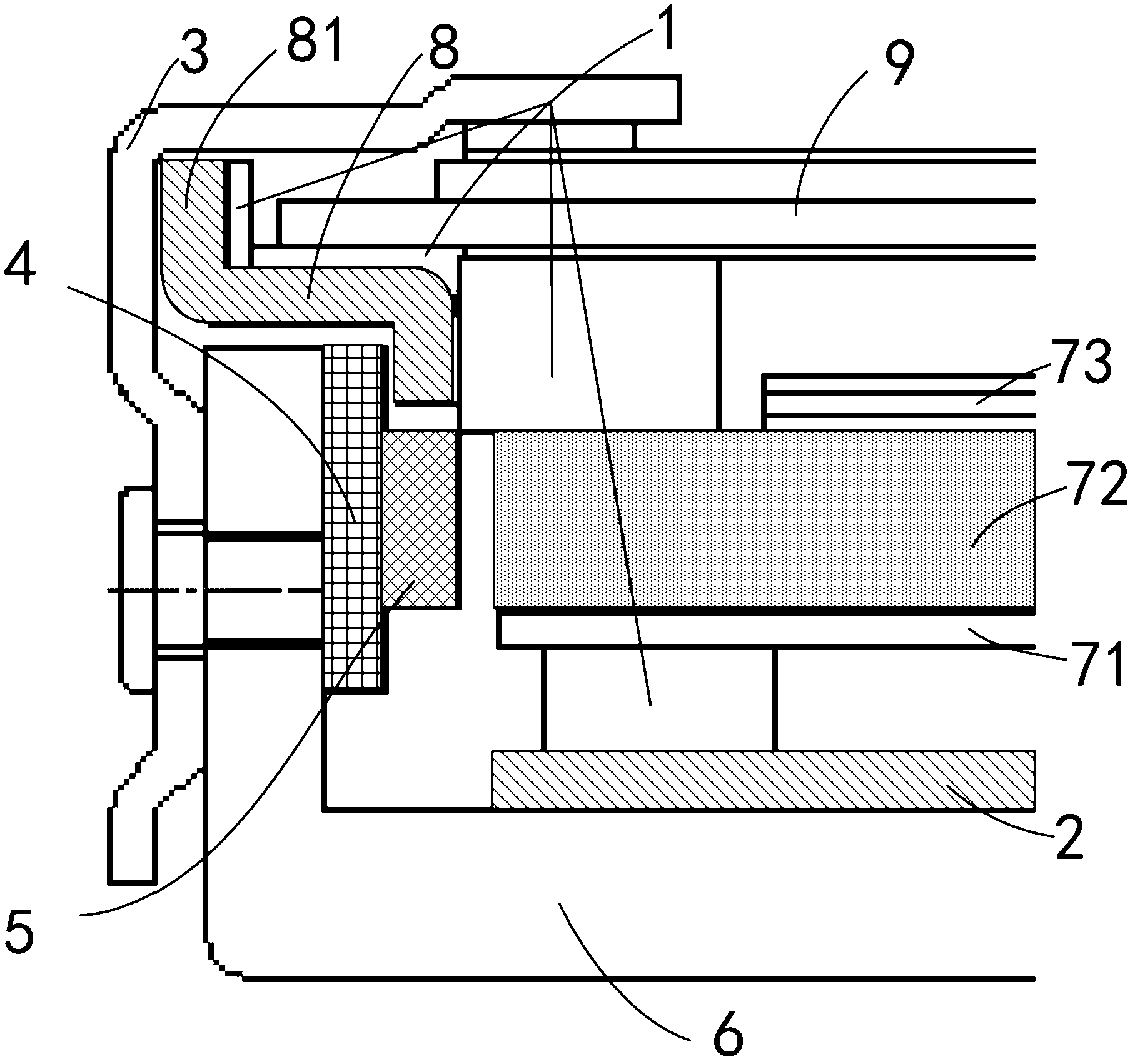

[0029] One end of the light source fixing device 6 fixing the LED5 light bar is located on the side of the light guide plate 72, and a positioning plate 8 is arranged between the top of the end and the liquid crystal display 9; 9 the first end portion 81 between the side and the front frame 3. The positioning plate 8 increases the clamping force on the liquid crystal display 9 , and the first end 81 can limit the side of the liquid crystal display 9 . Preferably, a buffer material 1 can be added on the surface of the positioning plate 8 in contact with the liquid crystal display 9 , and a buffer material 1 can also be added between the liquid crystal display 9 and the light guide plate 72 to increase the clamping force. Adding buffer material 1 to the side and bottom of the liquid crystal display 9 can give the liquid crystal display 9 better clamping force, and at the same time the liquid crystal display 9 is not easily crushed. In addition, the buffer material 1 added at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com