Optimal design method of cross-flow fan based on orthogonal test

A cross-flow fan and optimized design technology, which is applied to mechanical equipment, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problem of backward technology of cross-flow fans, poor environmental adaptability, and insufficient air volume Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

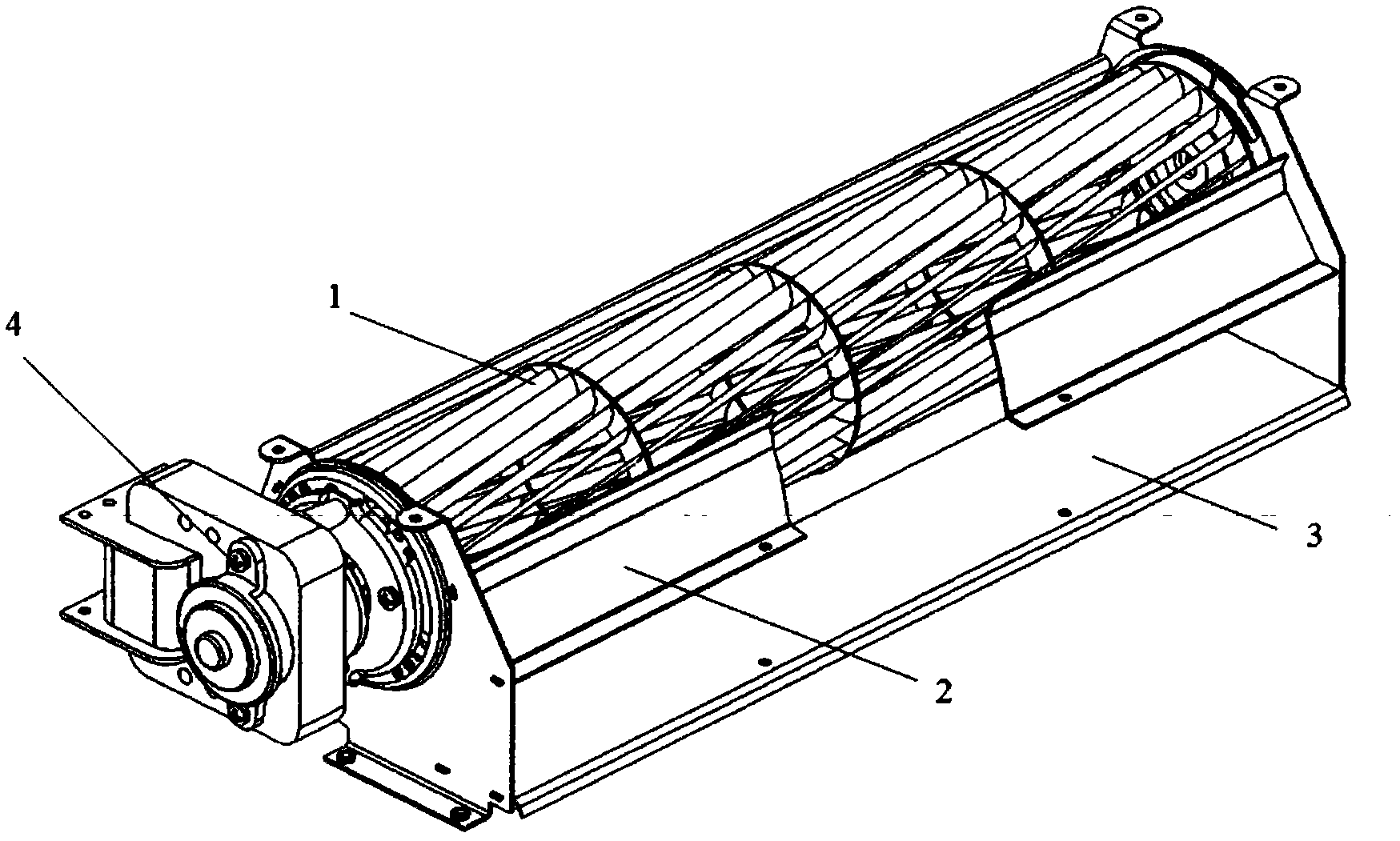

[0027] figure 1 It is a three-dimensional schematic diagram of the whole machine of the cross-flow fan of the present invention. The fan blades adopt twisted blades 1, and the twisted blades 1 are distributed equidistantly along the circumferential direction of the impeller. In the axial length direction of the entire cross-flow fan, each blade is twisted The angle is the blade twist angle. The motor 4 drives the impeller 5 to rotate, 2 is a volute tongue, and 3 is a volute.

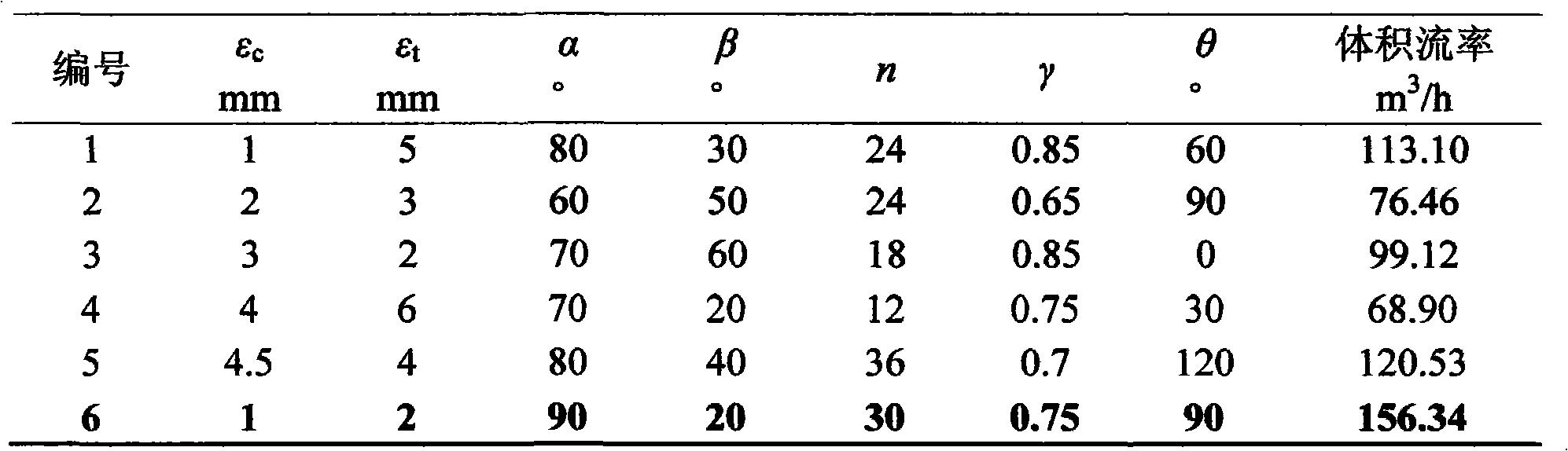

[0028] Such as figure 2 As shown, D is the outer diameter of the impeller (unit mm), d is the inner diameter of the impeller (unit mm), α is the inner circumference angle of the blade (unit °), β is the outer circumference angle of the blade (unit °), ε c is the clearance of the volute (in mm), ε t is the volute tongue gap (in mm), n is the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com