A Free Boundary Simulator for Horizontal Vibration Experiments

A simulation device and experiment technology, which is applied in the field of free boundary simulation device of horizontal vibration experiment, can solve the problems such as the inability to meet the three-way vibration reduction and isolation, and achieve the effect of improving the research level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

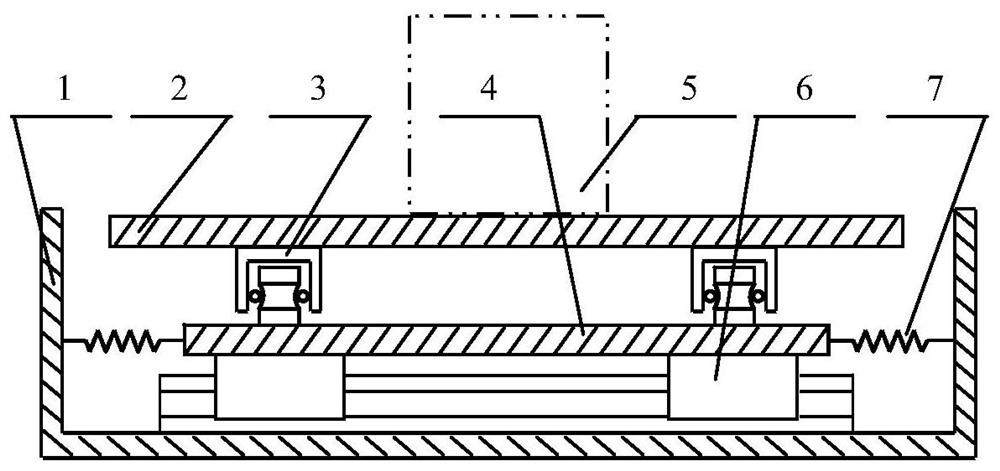

[0025] Specific implementation mode one: refer to Figure 1 to Figure 3 To illustrate this embodiment, this embodiment provides a free boundary simulation device for horizontal vibration experiments, the simulation device includes a box body 1, an upper platform assembly, a lower platform assembly, an upper level adjustment unit and a lower level adjustment unit;

[0026] The top of the box body 1 is provided with an opening, the upper platform assembly and the lower platform assembly are all arranged in the box body 1, the bottom of the lower platform assembly is fixed on the bottom plate in the box body 1, and the bottom of the upper platform assembly is fixed on the The lower platform assembly is on the platform surface, and the lower platform assembly is connected to one set of opposite inner walls of the box 1 through the lower level adjustment unit, and the upper platform assembly is connected to another set of opposite inner walls of the box 1 through the upper level adj...

specific Embodiment approach 2

[0028] Specific implementation mode two: refer to Figure 1 to Figure 3 Describe this embodiment. This embodiment is to further limit the lower platform assembly described in the first specific embodiment. In this embodiment, the lower platform assembly includes a lower platform 4 and two lower rail units 6;

[0029] The lower guide rail unit 6 includes a No. 1 guide rail and two No. 1 sliders, the two No. 1 sliders are arranged on the No. 1 guide rail, and the two No. 1 sliders are slidably connected to the No. 1 guide rail;

[0030] The two lower rail units 6 are arranged relatively parallel, and the bottom of the No. 1 rail in each lower rail unit 6 is fixedly connected to the bottom plate in the box body 1, and the lower platform 4 is arranged on the two lower rail units 6, and the lower platform The bottom of 4 is fixedly connected with each No. 1 slide block, and the lower platform 4 is connected with a group of opposite inner walls in the box body 1 through the lower le...

specific Embodiment approach 3

[0031] Specific implementation mode three: refer to Figure 1 to Figure 3 Describe this embodiment. This embodiment is to further limit the lower level adjustment unit described in the second specific embodiment. In this embodiment, the lower level adjustment unit includes two lower spring groups, and each lower spring group includes Two lower springs 7, and the axes of the two lower springs 7 are arranged in parallel, and the two lower spring groups are respectively arranged on opposite sides in the lower platform 4, and one end of each lower spring 7 is fixed to one side of the lower platform 4 The other end of each lower spring 7 is fixedly connected with the inner wall of the corresponding box body 1 . Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com