Four-step energy-saving cold-bridge-free heat insulation plate for dwelling house

A technology for insulation boards and housing, applied in covering/lining, construction, climate sustainability, etc., can solve problems such as high cost, multiple processes, and out-of-sync life of insulation materials, so as to improve standardization, reduce dehumidification operations, and improve the overall The effect of the level of modernization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

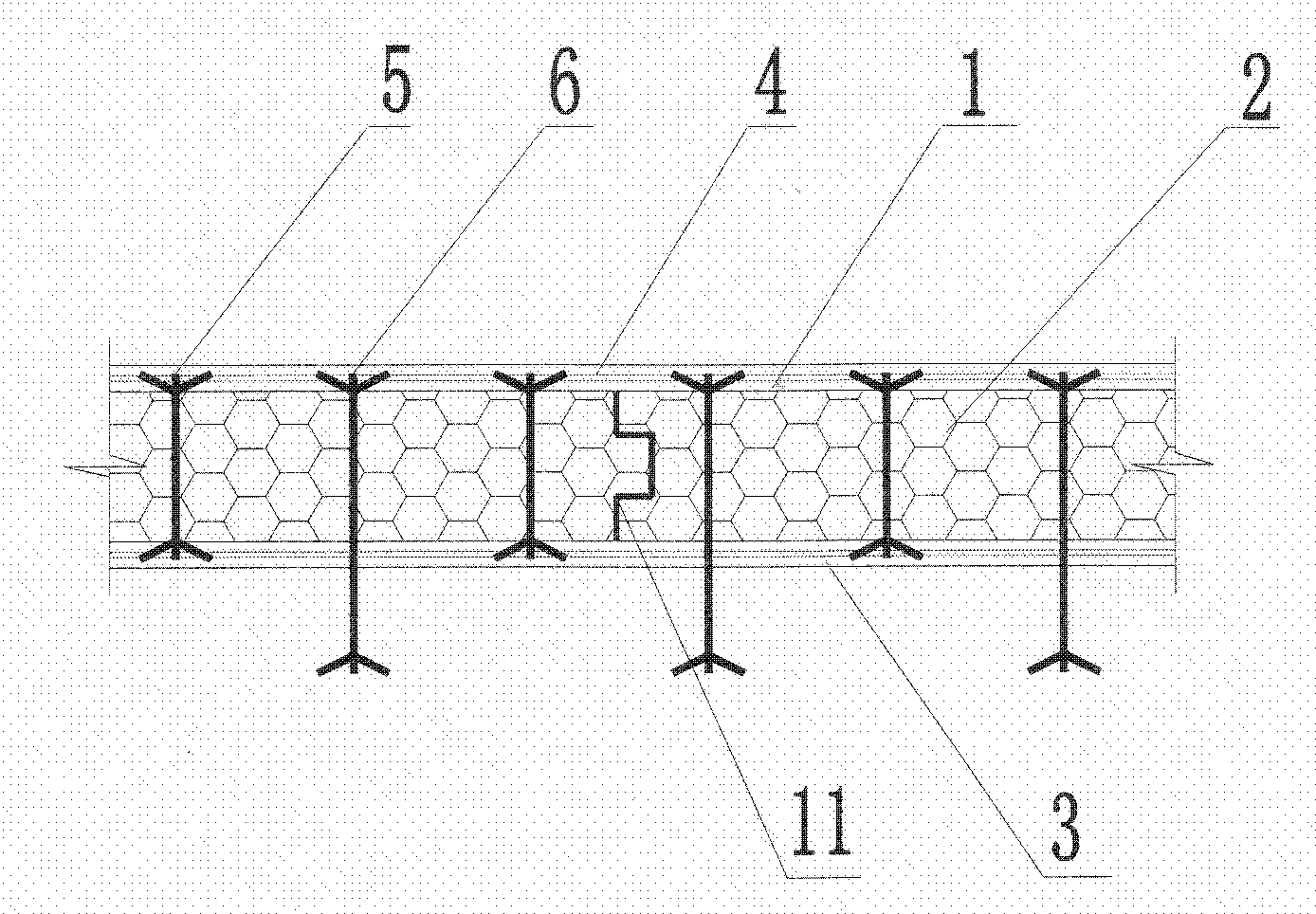

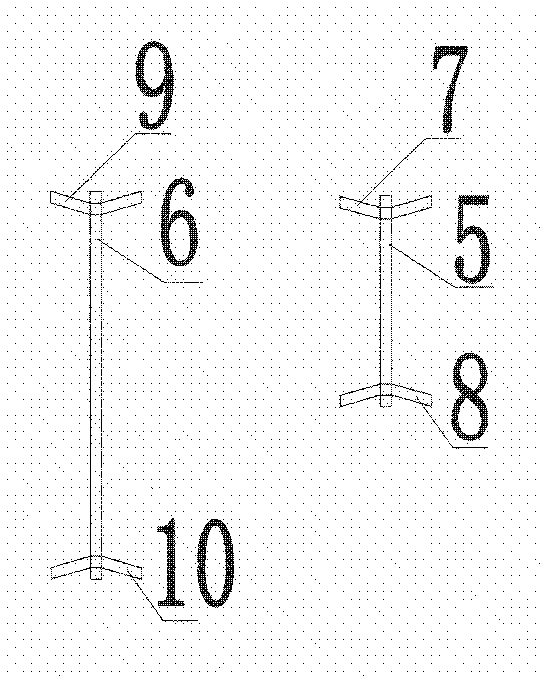

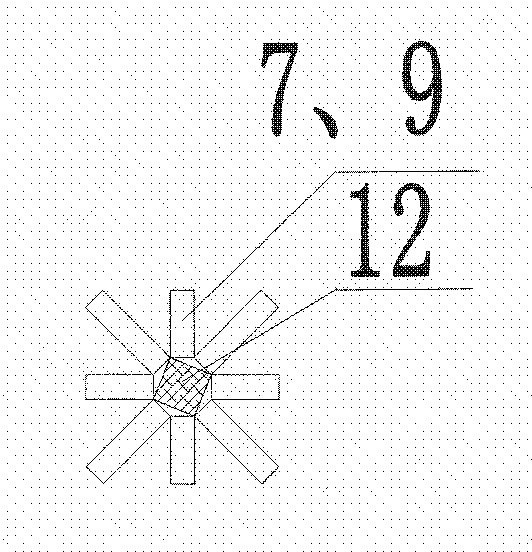

[0020] In order to further understand the characteristics and effects of the invention of the present invention, the following embodiments are given, and detailed descriptions are as follows in conjunction with the accompanying drawings, please refer to Figure 1-Figure 3 .

[0021] like figure 1 Shown: Four-step energy-saving residential thermal insulation board without cold bridge includes outer high-strength gypsum board layer 1, light insulation material layer 2, inner high-strength gypsum board layer 3, fiber reinforcement 4, A connection reinforcement 5, B connection reinforcement 6 and waterproofing agent; from the outside to the inside are the outer high-strength gypsum board layer 1, the light insulation material layer 2, and the inner high-strength gypsum board layer 3; each layer is composed of uniformly distributed and staggered A connecting ribs 5 and B connecting ribs 6 connection; the lightweight thermal insulation material in the lightweight thermal insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com