Arrangement method for down feathers with antibacterial function

A down and functional technology, which is applied in the field of antibacterial function down finishing, can solve the problems of down performance damage, loss of antibacterial function of down products, serious environmental pollution, etc., and achieve the effect of not reducing the antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of chitosan with different molecular weight and degree of acetylation:

[0019] Preparation scheme of chitosan with different molecular weights: high polymer chitosan (molecular weight 1.85×10 5 , the degree of deacetylation is 70%) under the condition of pH 3.0-4.5, the process adopts glacial acetic acid to adjust the pH value, and the concentration is 30% H 2 o 2 Degradation, where high polymer chitosan and 30% H 2 o 2 The mass ratio of the chitosan solution is 1:1.05-1.2; the degradation temperature is 80-85°C, and the degradation time is 2-2.5h; after the degradation is completed, the pH value of the degraded chitosan solution is adjusted to 8.5-9 with NaOH solution, and then suction filtered and evaporated. water, vacuum-dried, by controlling different oxidative degradation reaction conditions such as H 2 o 2 Concentration, reaction temperature, reaction time, pH value, etc., can prepare chitosan with different molecular weights. h 2 o 2 The hig...

Embodiment 2

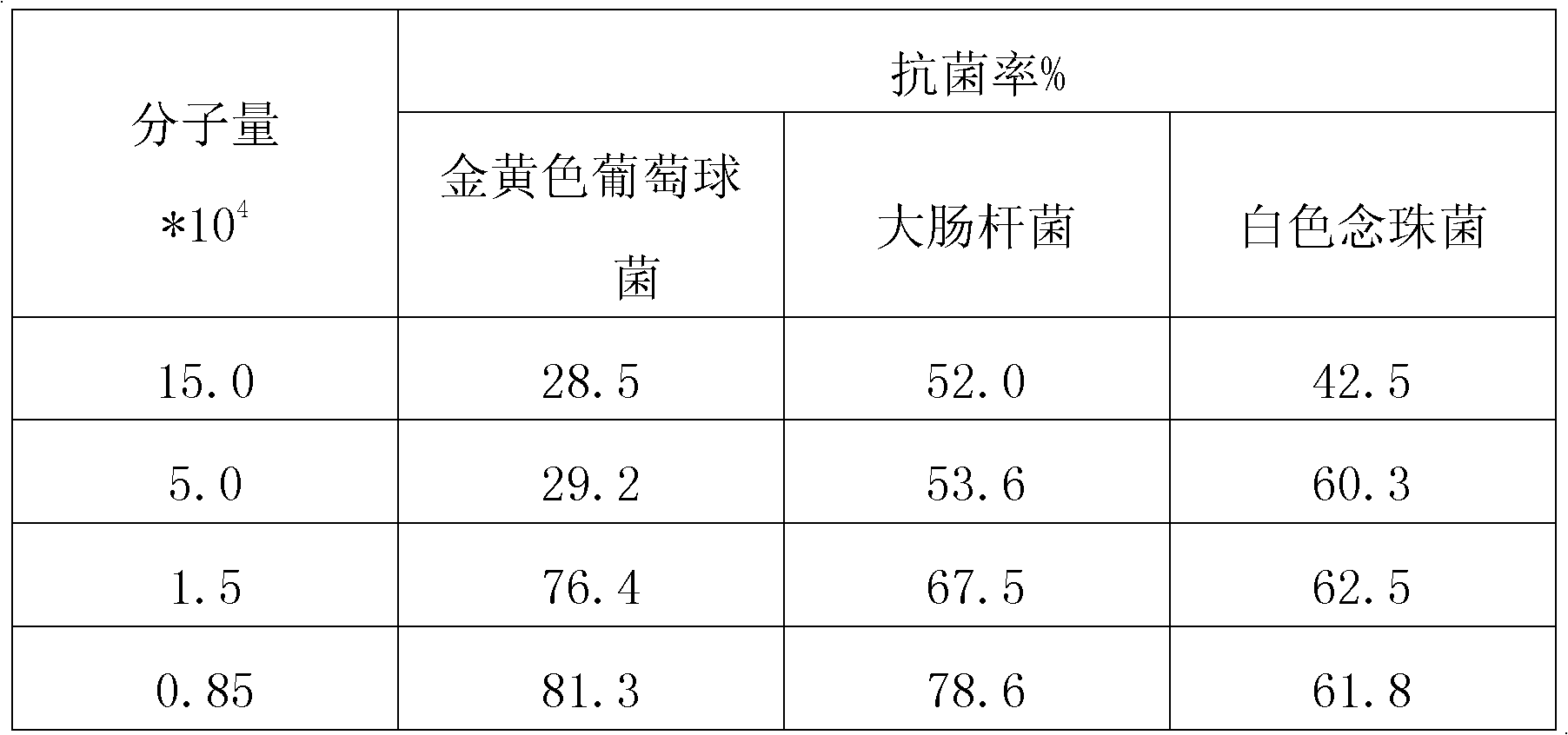

[0022] Effect of Chitosan Molecular Weight on Antibacterial Properties of Finished Down

[0023] Take 10kg of white duck down, after the dehydration process, use chitosan antibacterial finishing, test the effect of different molecular weight chitosan on the antibacterial rate of down. Other process conditions are: the degree of deacetylation of chitosan is 80.0%, the concentration of chitosan in the finishing solution is 20g / l; dipping for 10 minutes, one dipping and one rolling, the liquid rolling rate is 300%, 100 ° C opening and drying Dry.

[0024] Table 1. The effect of chitosan with different molecular weights on the antibacterial properties of down

[0025]

[0026] Note: Antibacterial performance is tested according to FZ / T 73023-2006

[0027] It can be seen from Table 1 that the molecular weight of chitosan has a great influence on the antibacterial properties of down. The smaller the molecular weight of chitosan, the better the antibacterial effect. This is bec...

Embodiment 3

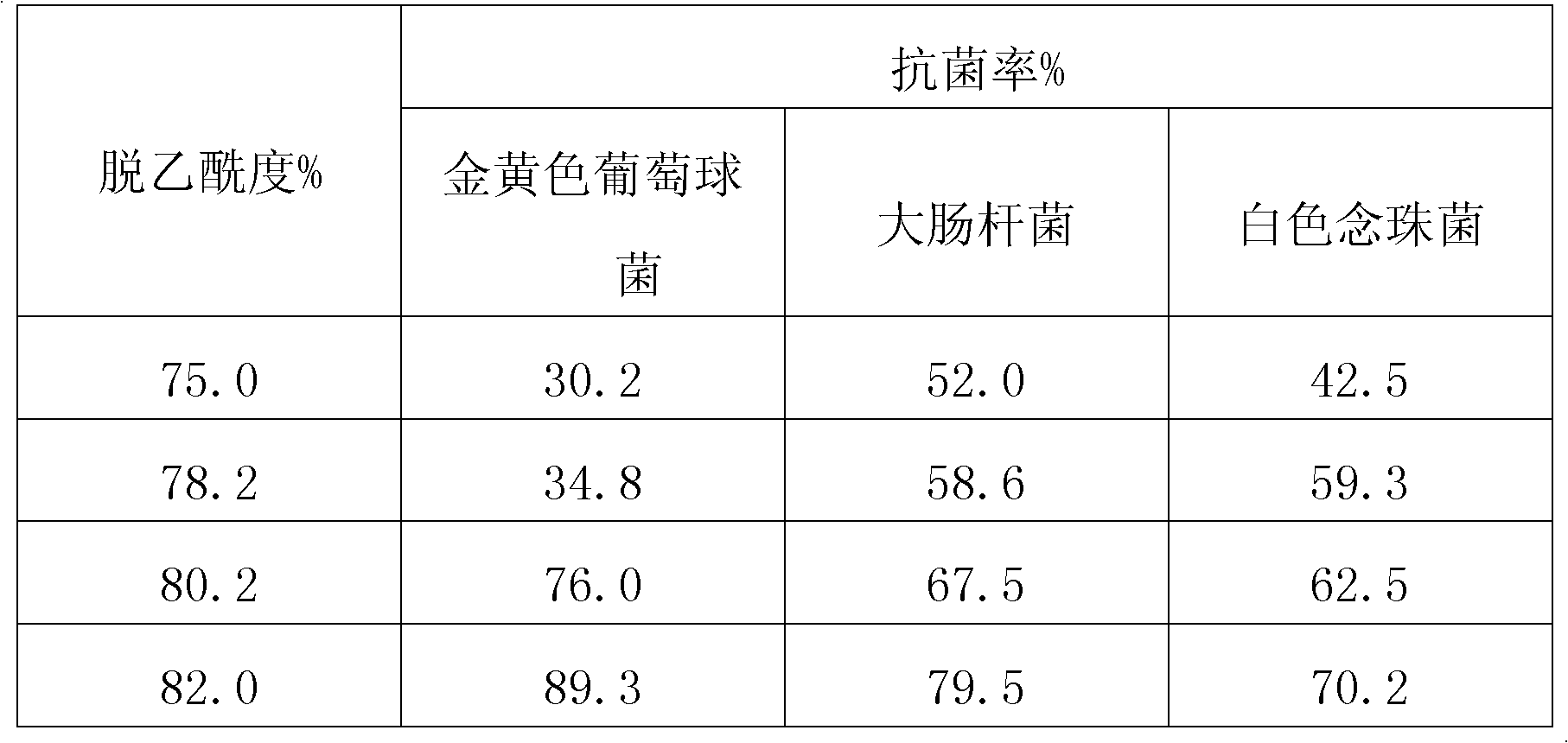

[0030] Effect of deacetylation degree of chitosan on antibacterial properties of finished down

[0031] Take 10kg of white duck down, after the dehydration process, use chitosan for antibacterial finishing, and test the effect of chitosan with different degrees of deacetylation on the antibacterial rate of down. Other process conditions are: the molecular weight of chitosan is 1.5*10 4 , the concentration of chitosan in the finishing solution is 20g / l; dipping for 10min, one dipping and one rolling, the liquid rolling rate is 300%, and it is opened and dried at 100°C.

[0032] Table 2. The effect of chitosan with different degrees of deacetylation on the antibacterial properties of down

[0033]

[0034] It can be seen from Table 2 that the down treated with chitosan with different degrees of deacetylation has different antibacterial properties, and with the increase of the degree of deacetylation, the antibacterial properties of chitosan are significantly enhanced. Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com